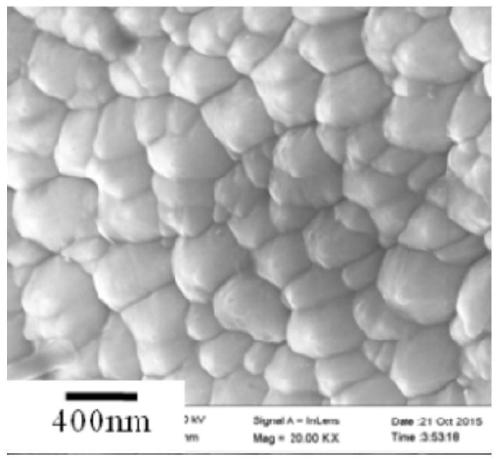

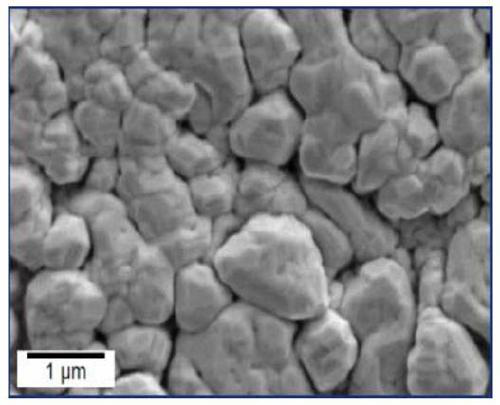

Method for preparing compact copper protection layer on surface of aluminum mold core

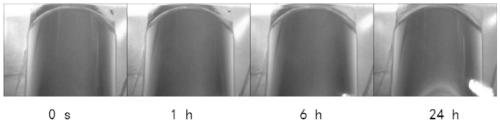

A protective layer and aluminum mold technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of non-dense copper protective layer, poor bonding force between copper protective layer and aluminum mold core, etc., to achieve Avoid the sharp increase of surface roughness, control the surface roughness, and prolong the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Embodiment 1: This embodiment is a method for preparing a dense copper protective layer on the surface of an aluminum mold core, which is specifically completed according to the following steps:

[0024] 1. Copper target pretreatment: first anneal the two copper targets, then put them into the coating device, and the center normal of the two copper targets is 90°, and then pre-sputter for 18 minutes to 22 minutes;

[0025] 2. Aluminum mold core assembly: Clean the aluminum mold core with acetone, absolute ethanol and deionized water in sequence, and then install it into the coating device to ensure that the distance between the aluminum mold core and the two copper targets is adjusted to 100mm-200mm. And the normal line of the center line of the two copper targets and the plane where the aluminum mold core is located are at an angle of 45°, and a baffle is set between the two copper targets and the aluminum mold core;

[0026] 3. Vacuum heating degassing treatment and i...

specific Embodiment approach 2

[0031] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the copper target described in step 1 is an oxygen-free copper target, and the purity of the oxygen-free copper target is >99.95%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the specific process of the annealing treatment described in Step 1 is as follows: two copper targets are annealed at a temperature of 650° C. 2h. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com