Mold for growing rare earth ion doped crystals with heterogeneous high-melting-point arc-shaped seed crystals and growth method

A rare earth ion, high melting point technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of low growth efficiency, easy melting of seed crystals, single growth type, etc., to achieve stable growth interface and reduce melt Volatile, no mechanical disturbance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

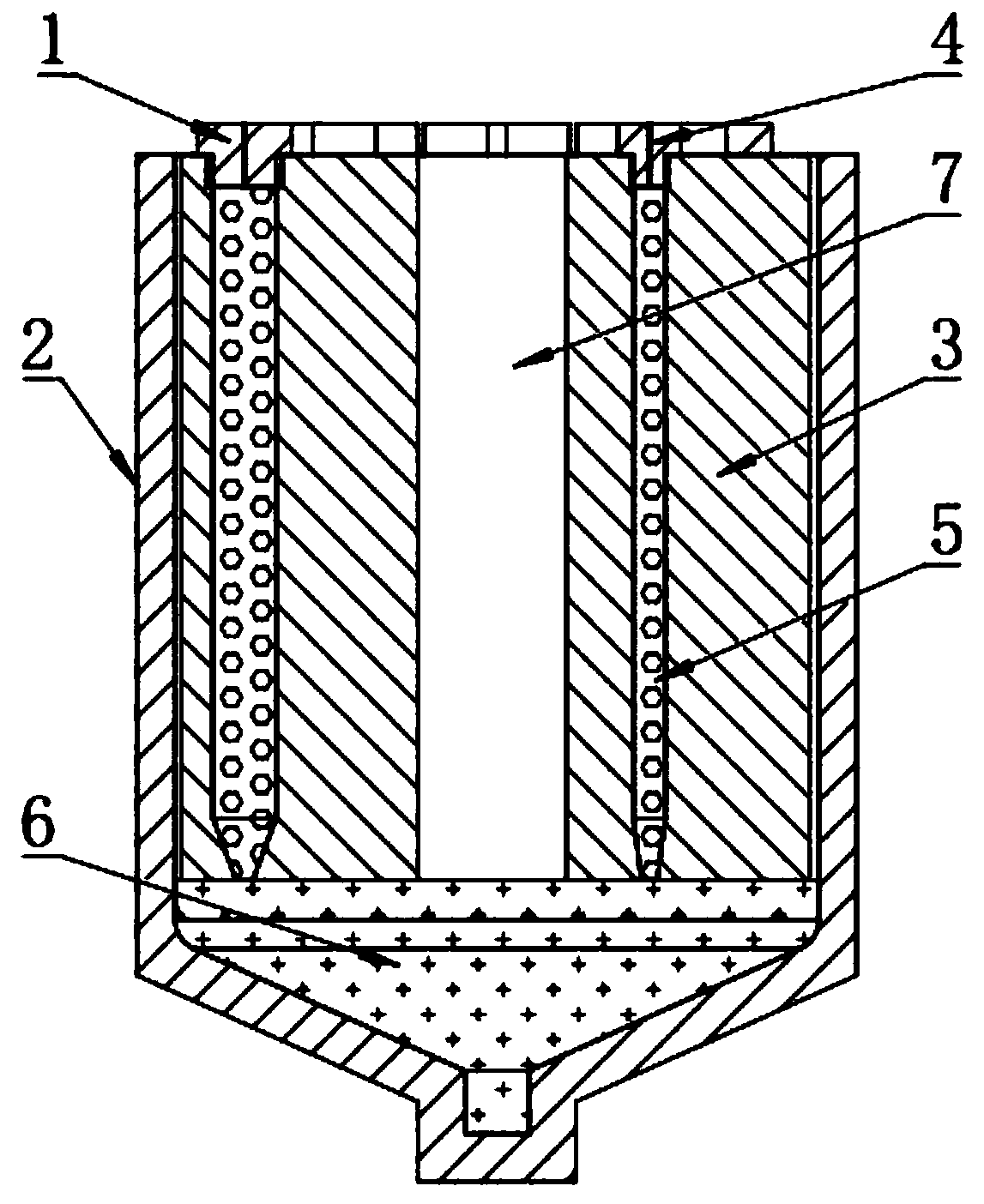

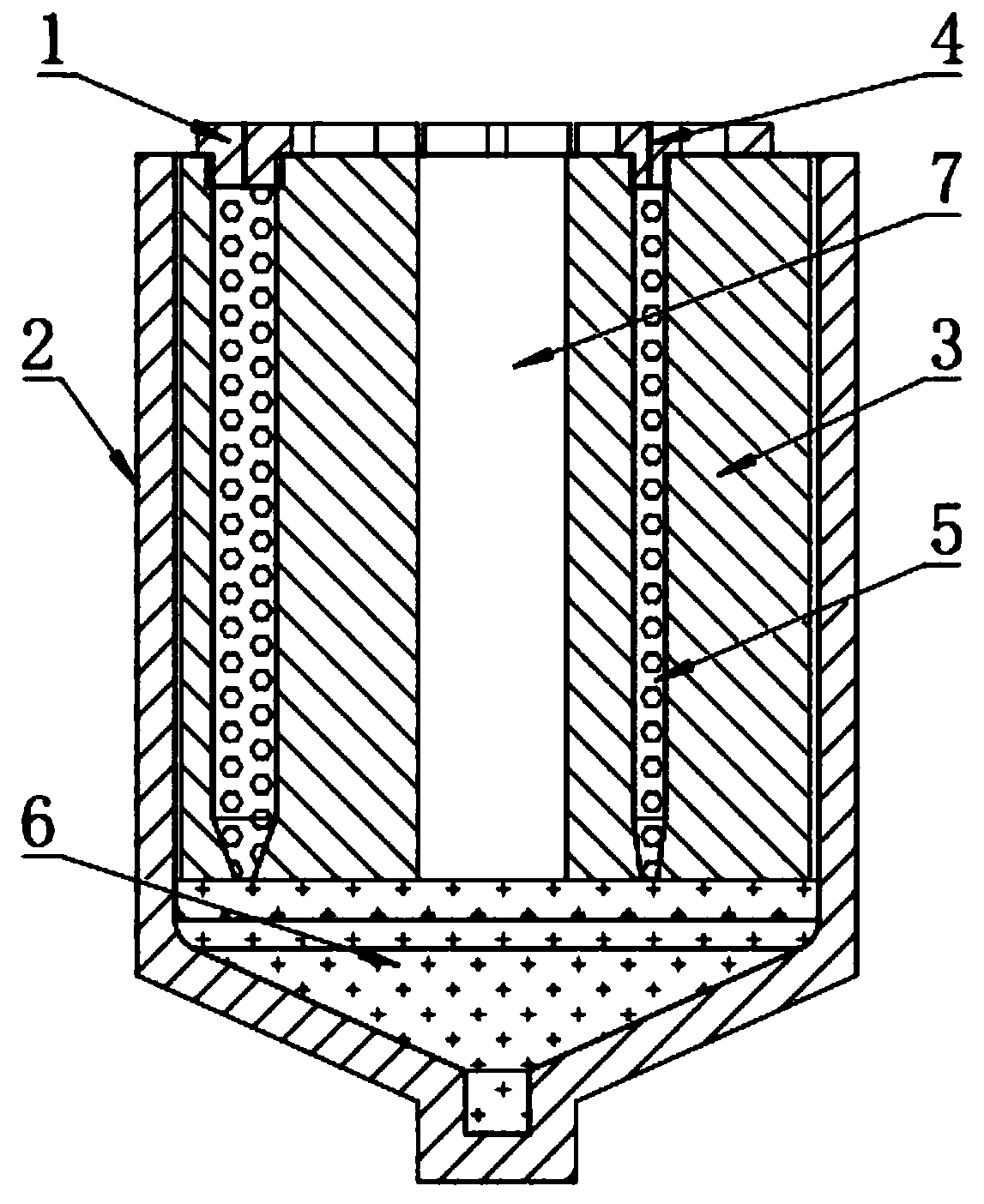

[0036] The mold used was a 12 cylinder mold with a diameter of 10 mm and a length of 210 mm.

[0037] S01, firstly, an arc-shaped pure calcium fluoride crystal seed crystal is placed in the arc-shaped seed crystal region 6 of the crucible 2 . According to Dy x Pb (1-x) f 2+x (x=0.01, 0.02, 0.03...) Chemical formula, weigh all high-purity raw materials and 1% oxygen scavenger of the total mass of raw materials in proportion, mix well and put them into cylindrical molds respectively, and screw on the crucible cover;

[0038] S02, vacuumize, and pass helium gas as a protective atmosphere;

[0039] S03, heating up to 150°C, and keeping it warm for 5 hours, to remove the moisture in the raw materials;

[0040] S04, continue to heat up until the raw materials are completely melted, and heat-treat at a constant temperature for 5 hours;

[0041] S05, slowly lower the temperature at 0.5-1.0°C / h to crystallize the melt in the crucible from bottom to top;

[0042]S06, after the cry...

Embodiment 2

[0045] The mold used was a 24 cylinder mold with a diameter of 20 mm and a length of 210 mm.

[0046] S01, firstly, an arc-shaped pure YAG crystal seed crystal is placed in the arc-shaped seed crystal region 6 of the crucible 2 . According to Ca 3 Nb 1.6875 Ga 3.1875 o 12 and xRe 3 Ga 5 o 12 (Re=Pr, Dy, Ho, Tb..., x=0.01, 0.02, 0.03...) chemical formula, weigh all the high-purity raw materials in proportion, mix them well and press them, and sinter them at high temperature, and then put them into cylindrical molds Inside, screw on the crucible lid;

[0047] S02, vacuumize, and pass helium gas as a protective atmosphere;

[0048] S03, heating up to 200°C, and keeping it warm for 5 hours, to remove the moisture in the raw materials;

[0049] S04, continue to heat up until the raw materials are completely melted, and heat-treat at a constant temperature for 5 hours;

[0050] S05, slowly lower the temperature at 0.5-1.0°C / h to crystallize the melt in the crucible from bo...

Embodiment 3

[0054] The molds used were 22 cylindrical molds 3 with a diameter of 15 mm and a length of 240 mm.

[0055] S01, firstly, an arc-shaped pure YAG crystal seed crystal is placed in the arc-shaped seed crystal region 6 of the crucible 2 . According to Ca 3 Nb 1.6875 Ga 3.1875 o 12 and xRe 3 Ga 5 o 12 (Re=Pr, Dy, Ho, Tb..., x=0.01, 0.02, 0.03...) chemical formula, weigh all the high-purity raw materials in proportion, mix them well and press them, and sinter them at high temperature, and then put them into cylindrical molds 3, screw on the crucible cover 1;

[0056] S02, vacuumize, and pass helium gas as a protective atmosphere;

[0057] S03, heat up to 350°C, and keep it warm for 7 hours, to remove the moisture in the raw materials;

[0058] S04, continue to heat up until the raw materials are completely melted, and heat treatment at constant temperature for 3 hours;

[0059] S05, slowly lowering the temperature at 0.25-1.0°C / h to crystallize the melt in the crucible 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com