Mold for growth of transistor through heat exchange method and growth method of transistor by using mold

A heat exchange method and transistor technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problem of low utilization rate of crystal materials, and achieve the effects of saving manpower, smooth surface and regular appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

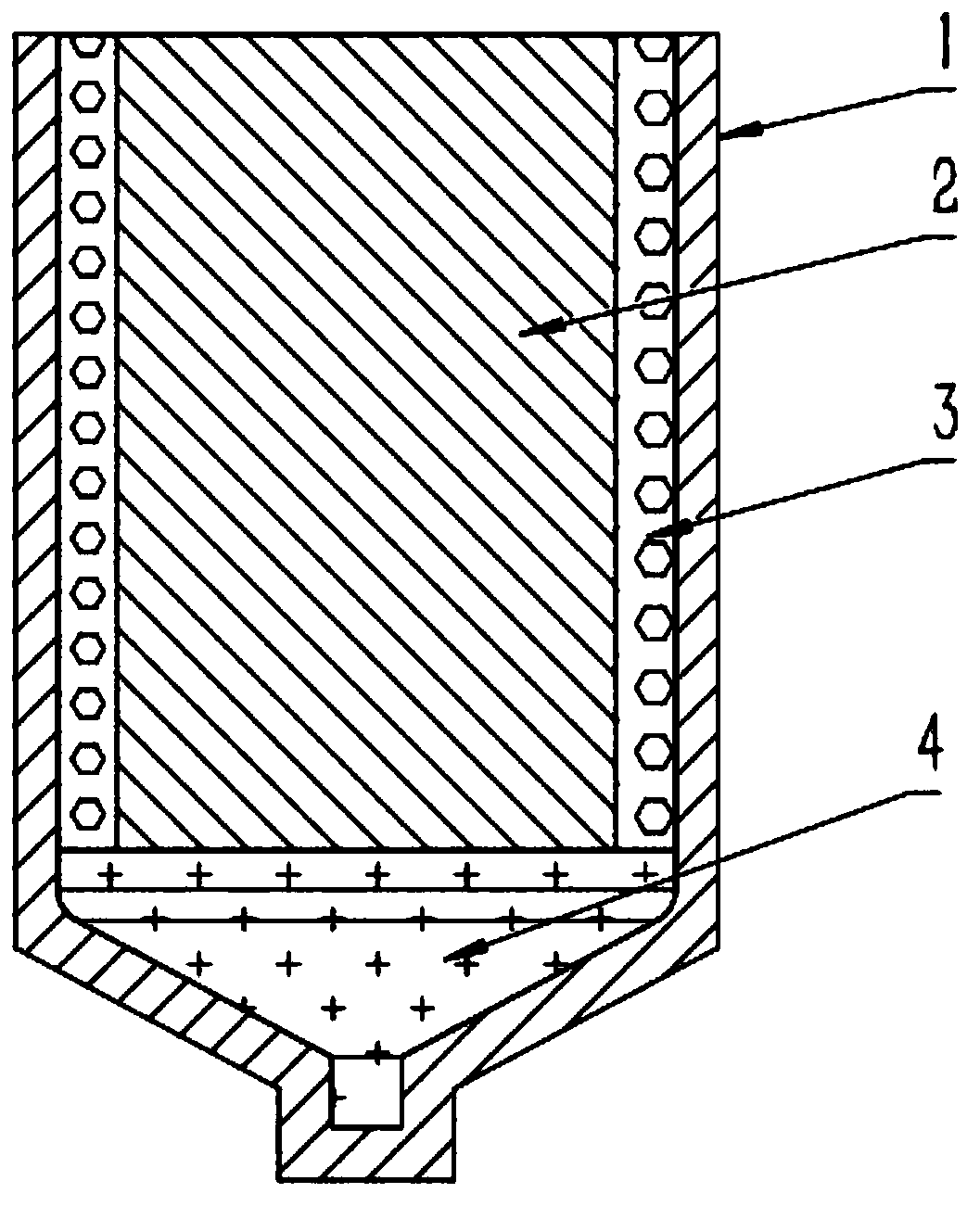

[0038] The inner diameter of the crucible 1 used is 200 mm, the diameter of the cylinder 2 is 190 mm, and the height is 260 mm.

[0039] S01, first the seed crystal area 4 is loaded into Y 3 Al 5 o 12 (YAG) seed crystal; loaded into cylinder 2 above; according to Y 3 Al 5 o 12 Chemical formula, weigh Y in proportion 2 o 3 、Al 2 o 3 High-purity raw materials are fully mixed and loaded into the transistor growth area 3;

[0040] S02, vacuumize, and pass inert gas as a protective atmosphere;

[0041] S03, raise the temperature until the raw material is completely melted, heat treatment at constant temperature for 17 hours, and control the seed crystal not to melt by controlling the power and the rate of feeding inert gas;

[0042] S04, slowly lower the temperature at 0.5-1.0°C / h to crystallize the melt in the mold from bottom to top;

[0043] S05, after the growth of the transistor is completed, drop to a certain temperature at 1.5-2.2°C / h to complete the annealing pro...

Embodiment 2

[0046] The inner diameter of the crucible 1 used is 100 mm, the diameter of the cylinder 2 is 80 mm, and the height is 260 mm.

[0047] S01, first load the sapphire seed crystal in the seed crystal area 4; install the above-mentioned cylinder 2; weigh the Al 2 o 3 High-purity raw materials are loaded into the transistor growth area 3;

[0048] S02, vacuumize, and pass inert gas as a protective atmosphere;

[0049] S03, raise the temperature until the raw material is completely melted, heat treatment at constant temperature for 15 hours, and control the seed crystal not to melt by controlling the power and the rate of feeding inert gas;

[0050] S04, slowly lower the temperature at 0.5-1.0°C / h to crystallize the melt in the mold from bottom to top;

[0051] S05, after the growth of the transistor is completed, drop to a certain temperature at 1.5-3.0°C / h to complete the annealing process;

[0052] S06, cooling down to room temperature at a cooling rate of 25-30° C. / h, takin...

Embodiment 3

[0054] The inner diameter of the crucible 1 used is 50 mm, the diameter of the cylinder 2 is 20 mm, and the height is 270 mm.

[0055] S01, first load the sapphire seed crystal in the seed crystal area 4; install the above-mentioned cylinder 2; weigh the Al 2 o 3 High-purity raw materials are loaded into the transistor growth area 3;

[0056] S02, vacuumize, and pass inert gas as a protective atmosphere;

[0057] S03, heat up until the raw material is completely melted, heat treatment at constant temperature for 8 hours, and control the seed crystal not to melt by controlling the power and the rate of feeding inert gas;

[0058] S04, slowly lower the temperature at 0.6-0.8°C / h, so that the melt in the mold crystallizes from bottom to top;

[0059] S05, after the growth of the transistor is completed, drop to a certain temperature at 2.5-3.0°C / h to complete the annealing process;

[0060] S06, cooling down to room temperature at a cooling rate of 10-30° C. / h, taking out the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com