Preparation method of electret polylactic acid meltblown nonwoven material

A non-woven material, polylactic acid technology, used in non-woven fabrics, rayon manufacturing, textiles and papermaking, etc., can solve problems such as poor charge storage performance, and achieve the effect of improving service life, low energy consumption, and improving charge storage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

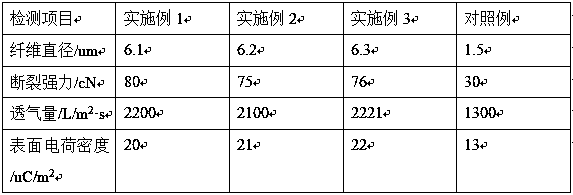

Embodiment 1

[0031] In parts by weight, weigh 20 parts of polytetrafluoroethylene, 1 part of nano-silicon nitride, 0.1 part of silane coupling agent KH-151, and 40 parts of deionized water, and mix nano-silicon nitride and silane coupling agent KH-151 Mix -151 with deionized water, stir magnetically at room temperature for 10 minutes at a stirring speed of 1500r / min to obtain a mixed solution, place the mixed solution in an ultrasonic cleaner for ultrasonic dispersion for 10 minutes to obtain a dispersion, filter to obtain a filter residue, and use Wash twice with deionized water, dry to constant weight at 60°C, and cool to room temperature to obtain the modified product. Mix the modified product and polytetrafluoroethylene in a high-speed food mixer to obtain a total The mixture is placed under a pressure of 30 MPa and pre-pressed for 10 minutes to obtain a pre-pressed product. The pre-pressed product is placed in a muffle furnace, and the temperature is raised to 100 ° C at a heating rate...

Embodiment 2

[0033] In parts by weight, weigh 25 parts of polytetrafluoroethylene, 3 parts of nano-silicon nitride, 0.2 parts of silane coupling agent KH-151, and 45 parts of deionized water, and mix nano-silicon nitride and silane coupling agent KH-151 -151 was mixed with deionized water, stirred magnetically at room temperature for 12min at a stirring speed of 1550r / min, and the mixed solution was obtained. The mixed solution was ultrasonically dispersed in an ultrasonic cleaner for 15min to obtain the dispersion, and filtered to obtain the filter residue, and used Wash 3 times with deionized water, dry to constant weight at 70°C, and cool to room temperature to obtain the modified product. Mix the modified product and polytetrafluoroethylene in a high-speed food mixer to obtain a total The mixture is placed under a pressure of 32 MPa and pre-pressed for 12 minutes to obtain a pre-pressed product. The pre-pressed product is placed in a muffle furnace, and the temperature is raised to 110 ...

Embodiment 3

[0035] In parts by weight, weigh 30 parts of polytetrafluoroethylene, 5 parts of nano-silicon nitride, 0.3 parts of silane coupling agent KH-151, and 50 parts of deionized water, and mix nano-silicon nitride and silane coupling agent KH-151 Mix -151 with deionized water, stir magnetically at room temperature for 15 minutes at a stirring speed of 1600r / min to obtain a mixed solution, place the mixed solution in an ultrasonic cleaner for ultrasonic dispersion for 20 minutes to obtain a dispersion, filter to obtain a filter residue, and use Wash with deionized water for 4 times, dry to constant weight at 80°C, and cool to room temperature to obtain the modified product. Mix the modified product and polytetrafluoroethylene in a high-speed food mixer to obtain a total The mixture is placed under a pressure of 35 MPa and pre-pressed for 15 minutes to obtain a pre-pressed product. The pre-pressed product is placed in a muffle furnace, and the temperature is raised to 120 ° C at a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com