Smoke gas composite tube waste heat recovery device

A waste heat recovery device and composite tube technology, applied in indirect heat exchangers, heat exchanger types, climate sustainability, etc., can solve the problems of environmental pollution, production shutdown losses, low efficiency, etc., and achieve high heat exchange efficiency and savings. Energy cost, effect of increased temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

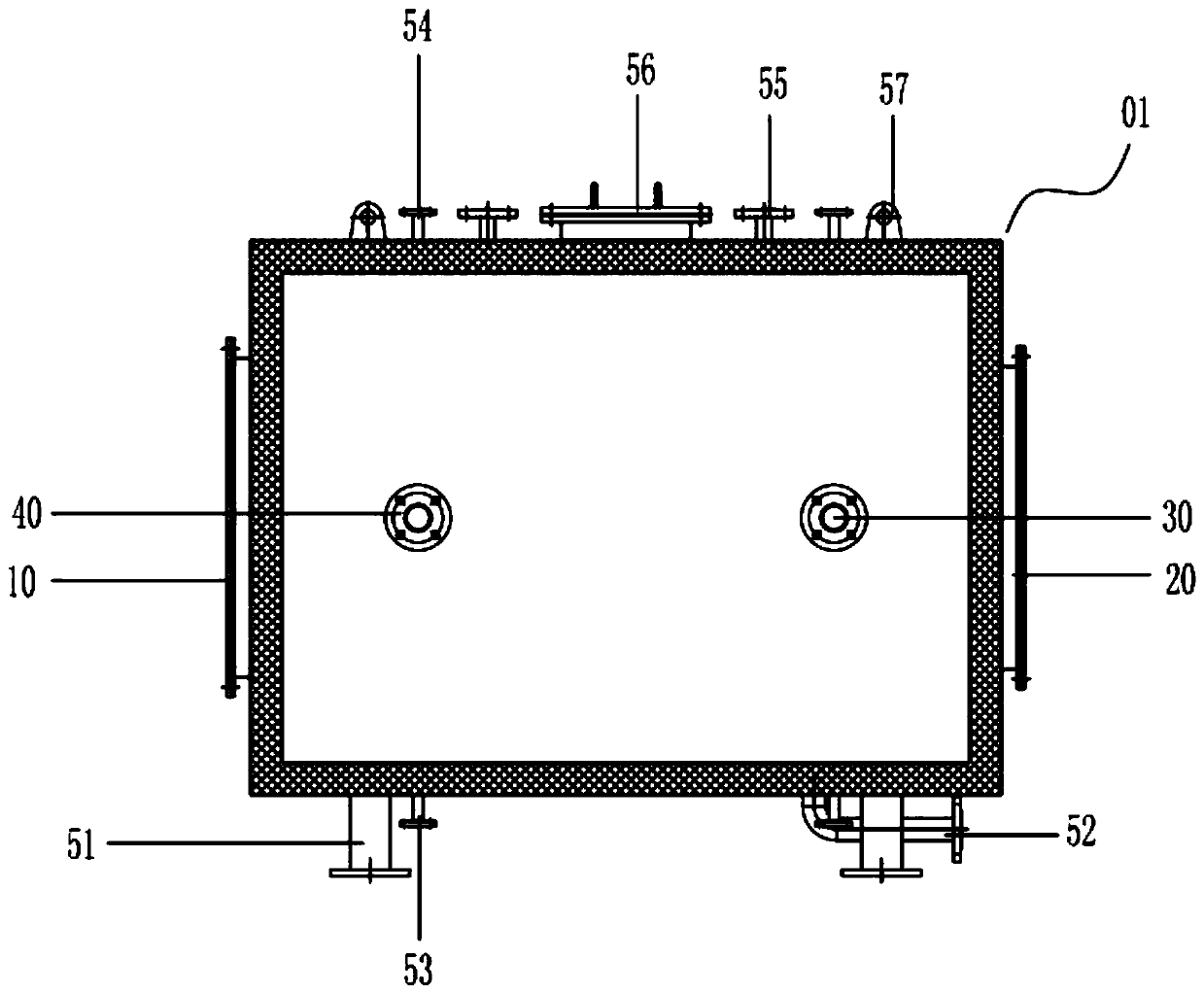

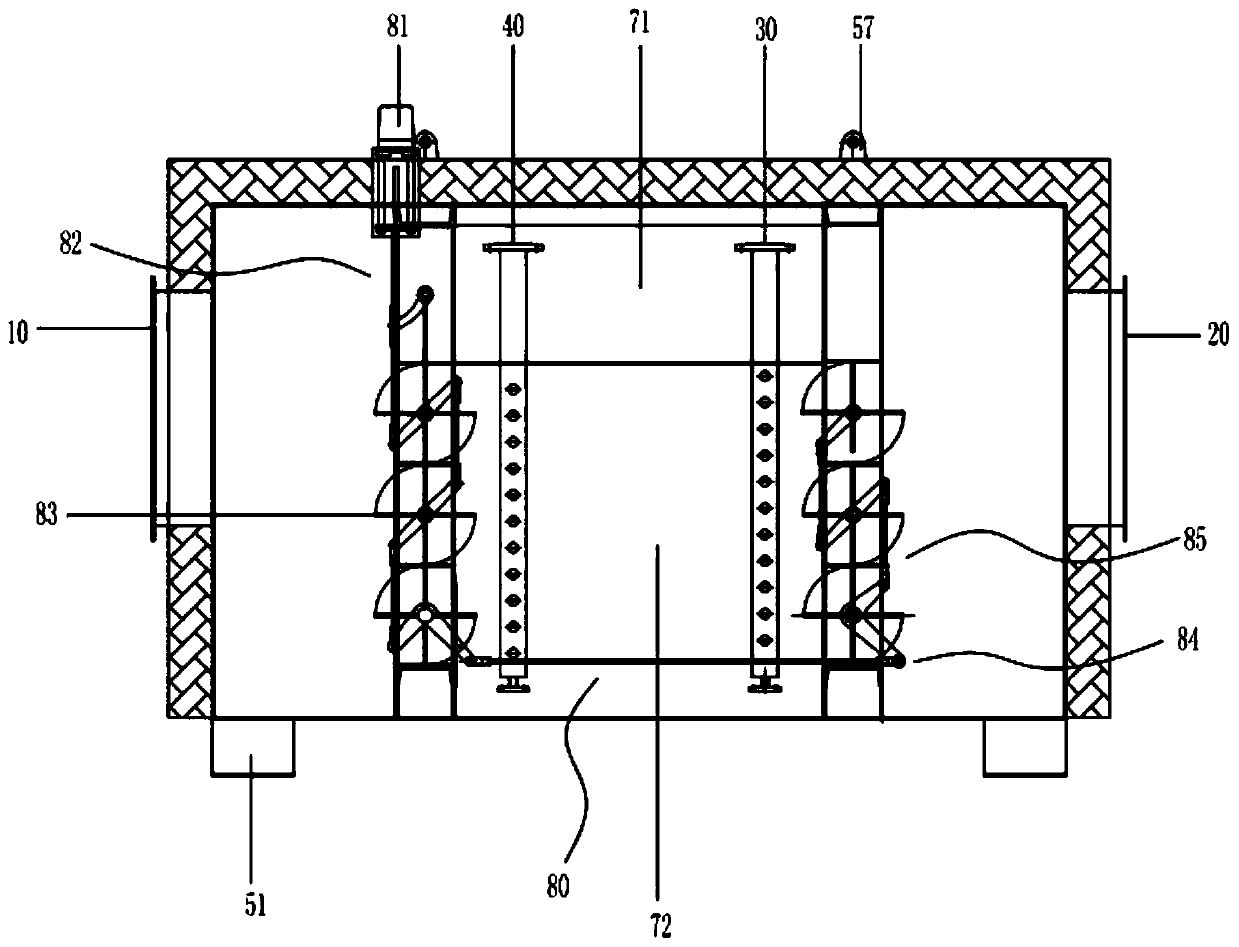

[0029] see Figure 1 to Figure 2 , is a flue gas composite pipe waste heat recovery device as Embodiment 1 of the present invention, which is mainly used for waste heat recovery and utilization of high-temperature flue gas discharged from automobile coating ovens. A plurality of heat exchange tubes, the outer casing is provided with a smoke inlet, a smoke outlet, a liquid inlet and a liquid outlet, the liquid inlet and the liquid outlet are arranged at both ends of the outer casing, and several heat exchange tubes are arranged side by side set, and the axis of the heat exchange tube is perpendicular to the axis of the liquid inlet and the liquid outlet. Specifically, the inside of the outer shell is covered with heat exchange tubes, and the heat exchange tubes are arranged in an array; at the same time, the flue gas passes through the smoke inlet It enters, passes through the heat exchange tube, and is discharged from the smoke outlet, while the circulating liquid enters throu...

Embodiment 2

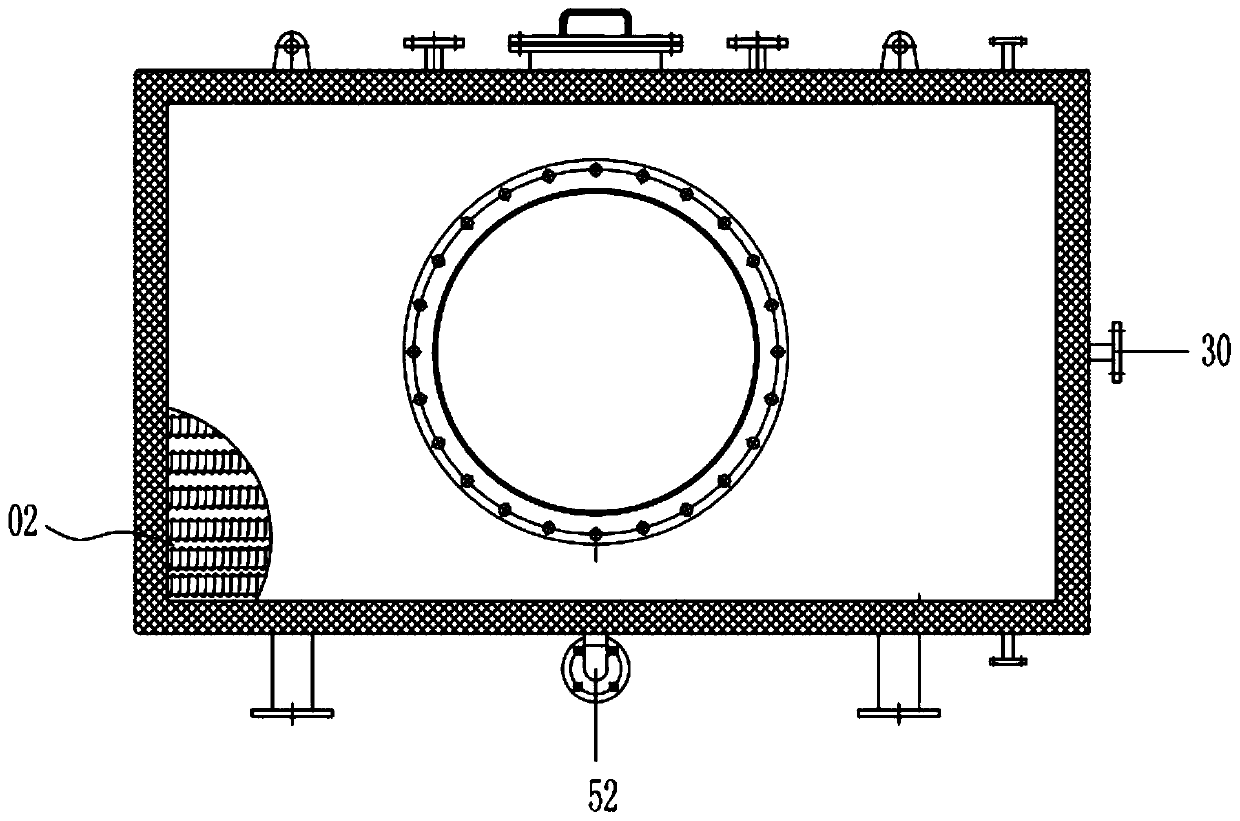

[0034] see Figure 3 to Figure 4 , is a flue gas composite pipe waste heat recovery device as Embodiment 1 of the present invention, which is mainly used for waste heat recovery and utilization of high-temperature flue gas discharged from an automobile coating incinerator. A plurality of heat exchange tubes, the outer casing is provided with a smoke inlet, a smoke outlet, a liquid inlet and a liquid outlet, the liquid inlet and the liquid outlet are arranged at both ends of the outer casing, and several heat exchange tubes are arranged side by side set, and the axis of the heat exchange tube is set perpendicular to the axis of the liquid inlet and the liquid outlet. Specifically, a first channel and a second channel are arranged inside the outer casing, and the inside of the second channel is covered with heat exchange tubes. And the heat exchange tubes are arranged in an array; when heat needs to be recovered, the second channel can be opened directly; at the same time, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com