Quantum dot photoelectric detector based on atomic layer deposition and preparation method thereof

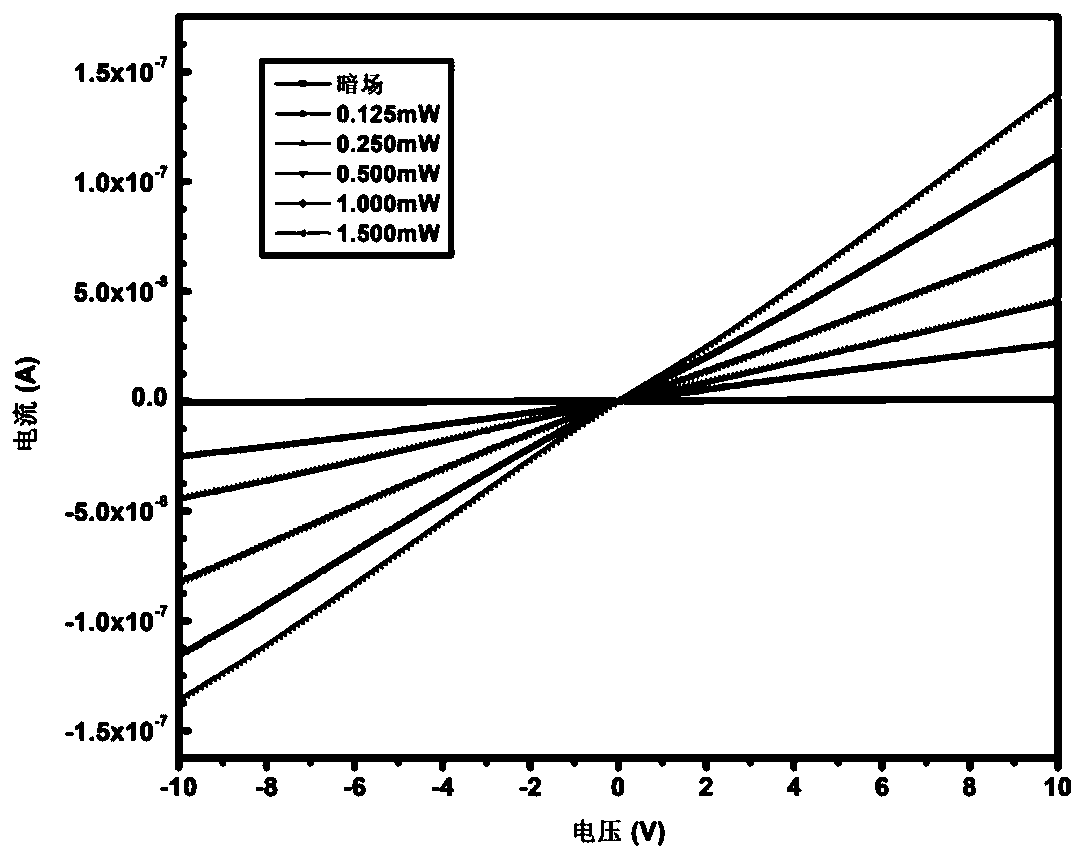

A photodetector, atomic layer deposition technology, applied in photovoltaic power generation, electric solid state device, semiconductor/solid state device manufacturing, etc. Slow device response speed and other problems, to achieve the effect of increasing life and mobility, reducing dark current, and improving the ratio of light to dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

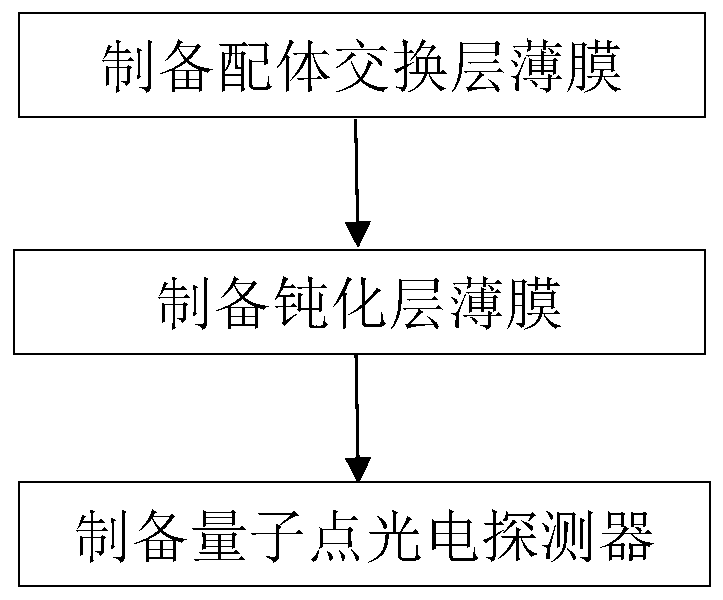

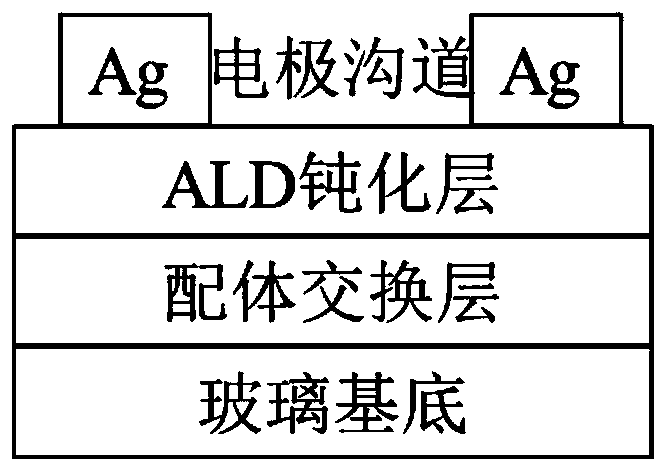

[0029] Such as figure 1 Shown, the present invention proposes a kind of preparation method based on the quantum dot photodetector of atomic layer deposition, and this method comprises the steps:

[0030] (a) Set the rotation speed of the spin coater at 1500rpm to 3000rpm, and the acceleration at 15m / s 2 ~30m / s 2 , the quantum dot solution is spin-coated on a clean substrate with a spin coater to obtain a single-layer quantum dot film with a thickness of 10nm to 50nm, and the first quantum dot is obtained by controlling the number of cycles of the spin coater to be 1 to 10 times film, the first quantum dot film is composed of 1-10 layers of single-layer quantum dot film, the thickness of the single-layer quantum dot film is preferably 10nm-50nm, and then the organic ligand solution is drip-coated on the first quantum dot Put it on the film and let it stand for 10s ~ 100s, after the ligand exchange is completed, wash it with a solvent such as methanol, acetonitrile or hexane, ...

Embodiment 1

[0044] (a) Configure a PbS solution with a concentration of 50mg / mL as the quantum dot solution, set the spin coater’s speed at 1500rpm, and the acceleration at 15m / s 2 , Spin-coat the PbS solution on a clean substrate with a spin coater to obtain a single-layer quantum dot film with a thickness of 50nm, cycle once to obtain the first quantum dot film, and then use the TBAI solution with a concentration of 1mg / mL as the organic compound The body solution is dripped on the first quantum dot film for 20s and left to stand for 10s, and after the ligand exchange is completed, it is washed with methanol, thereby completing the preparation of the ligand exchange layer film;

[0045] (b) Set the rotational speed of the spin coater to 1500rpm and the acceleration to 15m / s 2 , using a spin coater to spin-coat the PbS solution with a concentration of 5 mg / mL on the ligand exchange layer film to prepare a single-layer quantum dot film with a thickness of 50 nm, and then in the vacuum cha...

Embodiment 2

[0047] (a) Configure the PbSe solution with a concentration of 5mg / mL as the quantum dot solution, set the spin coating apparatus to rotate at 3000rpm, and accelerate at 30m / s 2 , Spin-coat the PbSe solution on a clean substrate with a spin coater to obtain a single-layer quantum dot film with a thickness of 10nm, cycle 10 times to obtain the first quantum dot film, and then use a CTAB solution with a concentration of 100mg / mL as the organic compound The body solution is dripped on the first quantum dot film for 60s and left to stand for 80s, and after the ligand exchange is completed, it is washed with methanol, thereby completing the preparation of the ligand exchange layer film;

[0048] (b) Set the rotational speed of the spin coater to 3000rpm and the acceleration to 30m / s 2 , using a spin coater to spin-coat the PbSe solution with a concentration of 50 mg / mL on the ligand exchange layer film to prepare a single-layer quantum dot film with a thickness of 10 nm, and then i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com