Fuel cell anode catalyst, preparation method thereof and proton exchange membrane fuel cell

A fuel cell and catalyst technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve the problems of high cost of proton exchange membrane fuel cells, poor resistance to carbon monoxide poisoning, and low activity of anode catalysts , to achieve the effect of improving the resistance to carbon monoxide poisoning, improving stability, and reducing platinum loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

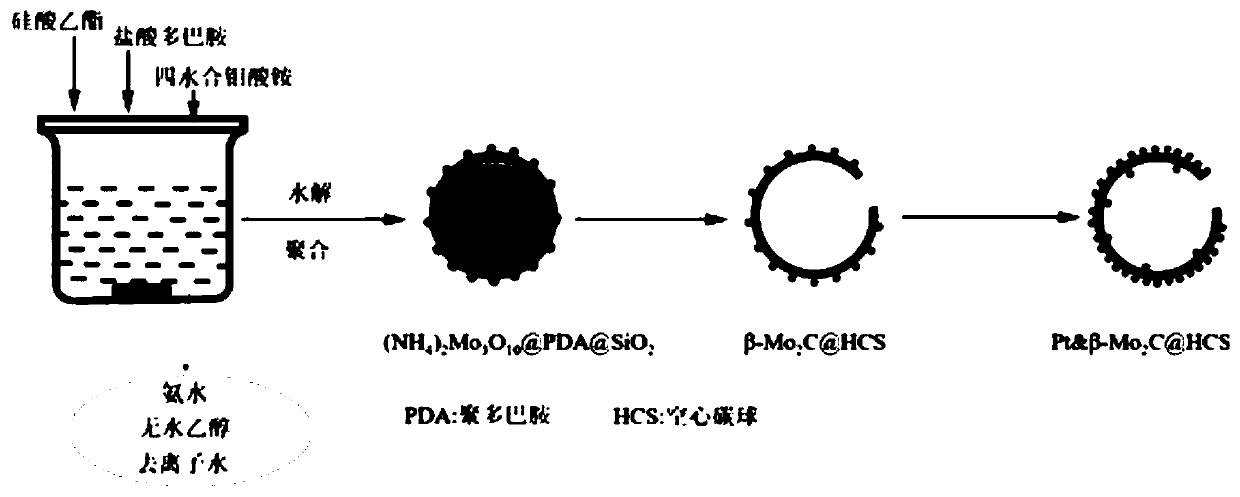

[0044] see figure 1 , the preparation method of the fuel cell anode catalyst comprises the following steps:

[0045]Step S01. Dissolving ammonia water in a mixed solvent of ethanol and deionized water to obtain an alkaline mixed solvent;

[0046] Step S02. adding ethyl silicate into the alkaline mixed solvent to obtain a mixed solution;

[0047] Step S03. Add dopamine hydrochloride to the mixed solution, add ammonium molybdate tetrahydrate after mixing, and evaporate to dryness at constant temperature to obtain the precursor material (the composition of the precursor material is: (NH 4 ) 2 Mo 3 o 10 @PDA @SiO 2 );

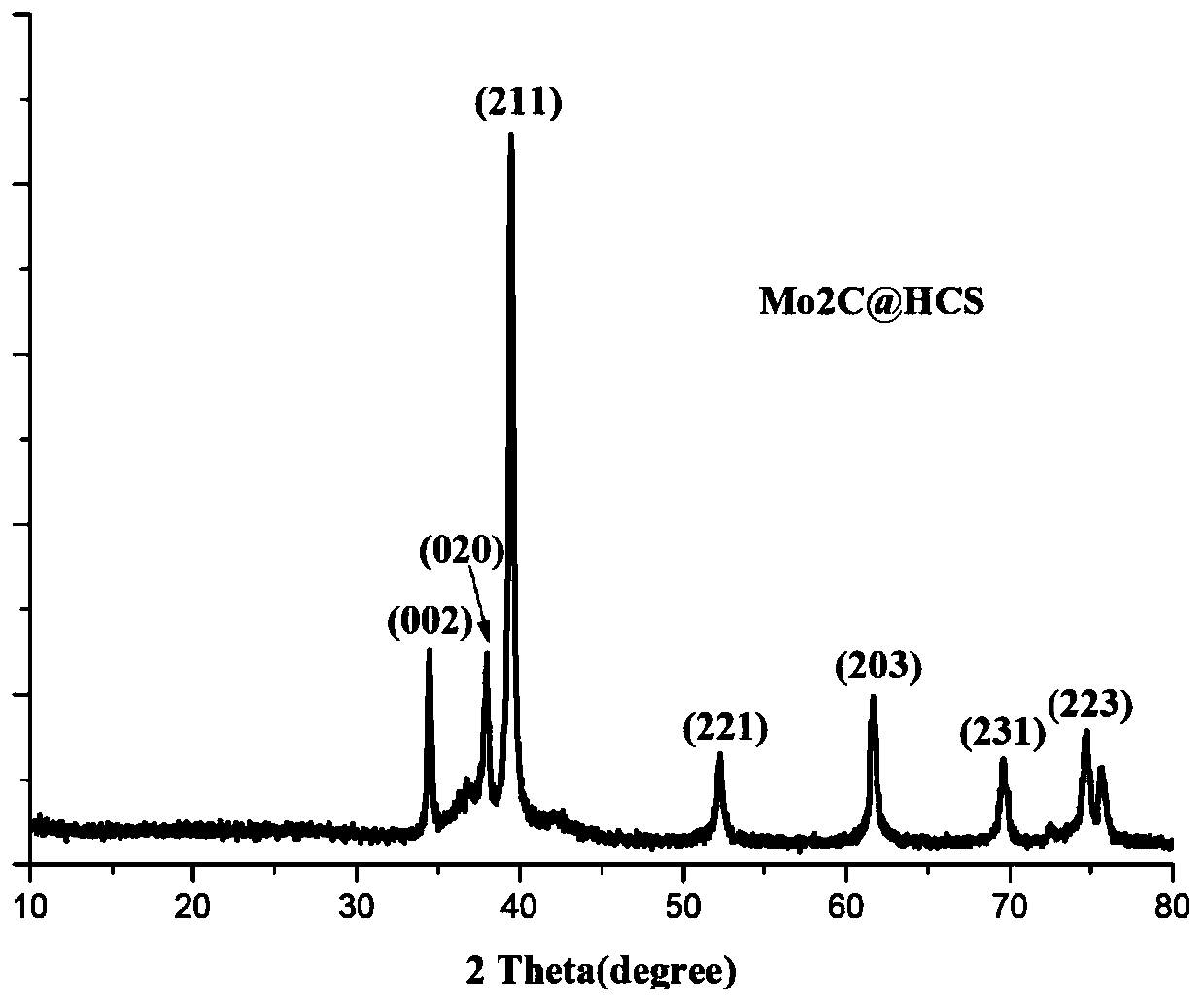

[0048] Step S04. Carry out heat treatment on the precursor material, pass through oxygen to carry out passivation treatment after natural cooling to room temperature; After passivation treatment, use hydrofluoric acid to carry out impregnation treatment, obtain molybdenum carbide@hollow carbon sphere (β-Mo 2 C@HCS);

[0049] Step S05. Impregnating and loadi...

Embodiment 1

[0072] A method for preparing a fuel cell anode catalyst, comprising the steps of:

[0073](a). Take a 500mL beaker, add 160mL of deionized water and 48mL of absolute ethanol to the beaker in turn, stir at room temperature for 15min at a speed of 600rpm, and mix well to obtain a mixed solvent.

[0074] (b). Add 2 mL of ammonia water with a mass concentration of 25% to 28% dropwise into the above mixed solvent, stir at room temperature for 30 min at a speed of 600 rpm, and mix evenly to obtain an alkaline mixed solution.

[0075] (c). Add 2 mL of ethyl silicate with a purity ≥ 98% dropwise into the above alkaline mixed solution, stir at room temperature for 30 min at a speed of 600 rpm, mix well, and then add 8 mL of prepared 100 mg / mL Add dopamine hydrochloride solution dropwise, and control the amount of dopamine hydrochloride entering the alkaline mixed solution to be (500-800) mg every (2-3) minutes; stir at room temperature at 600 rpm for 36 hours to fully react.

[0076]...

Embodiment 2

[0080] A method for preparing a fuel cell anode catalyst, comprising the steps of:

[0081] (a). Take a beaker with a capacity of 500mL, add 160mL of deionized water and 48mL of absolute ethanol to the beaker in turn, stir at room temperature for 15min at a speed of 600rpm, and mix well to obtain a mixed solvent.

[0082] (b). Add 2 mL of ammonia water with a mass concentration of 25% to 28% dropwise into the above mixed solvent, stir at room temperature for 30 min at a speed of 600 rpm, and mix evenly to obtain an alkaline mixed solution.

[0083] (c). Add 2 mL of ethyl silicate with a purity ≥ 98% dropwise into the alkaline mixed solution, stir at room temperature at 600 rpm for 30 min, mix well, and then add 8 mL of prepared hydrochloric acid with a concentration of 100 mg / mL For the dopamine solution, control the amount of dopamine hydrochloride entering the alkaline mixed solution to be (500-800) mg every (2-3) minutes; stir at room temperature for 36 hours at a speed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com