Milk protein grading membrane integrated treatment technology

A treatment process, milk protein technology, which is applied in the field of membrane integrated treatment process for milk protein grading, which can solve the problems of milk component damage, difficult cleaning, and easy pollution of organic membranes, and achieve reduced production costs, small footprint, and concentration multiples high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

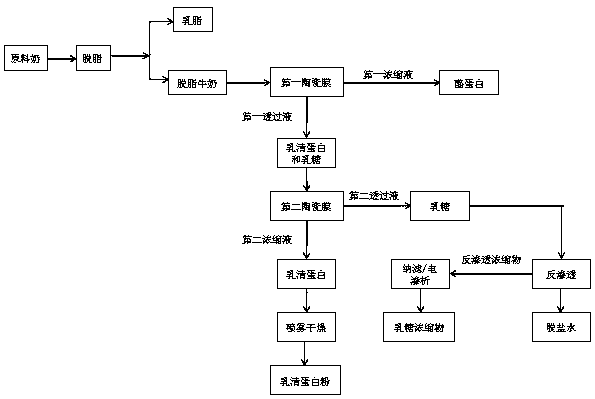

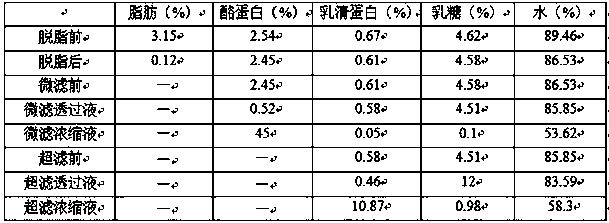

[0026] Such as figure 1 The present embodiment shown provides a membrane-integrated treatment process for milk protein fractionation, comprising the following steps:

[0027] Step 1: Preheat the raw milk first, the preheating temperature is 45°C, and then degrease the raw milk by centrifugal degreasing or membrane separation. In this embodiment, the centrifugal degreasing method is preferred, and the centrifugal speed is 5000r / min. The centrifugation time is 25 minutes, and the centrifugal degreasing temperature is 40°C to obtain skim milk and milk fat. After the milk fat is separated, store it for later use. It can be used as raw material for butter or cream. The fat content in skim milk is less than 0.5%;

[0028] Step 2: Separating the skim milk through the first ceramic membrane to obtain the first concentrate and the first permeate, wherein the first concentrate contains casein, the first permeate contains whey protein and lactose, and the first The ceramic membrane adop...

Embodiment 2

[0035] Such as figure 1 The present embodiment shown provides a membrane-integrated treatment process for milk protein fractionation, comprising the following steps:

[0036] Step 1: Preheat the raw milk first, the preheating temperature is 50°C, and then degrease the raw milk by centrifugal degreasing, the centrifugal speed is 4800r / min, the centrifugation time is 30min, and the centrifugal degreasing temperature is 50°C , to obtain skimmed milk and butterfat, and store the milkfat after separation for use as a raw material for butter or cream, and the fat content in the skimmed milk is less than 0.5%;

[0037] Step 2: Separating the skim milk through the first ceramic membrane to obtain the first concentrate and the first permeate, wherein the first concentrate contains casein, the first permeate contains whey protein and lactose, and the first The ceramic membrane adopts a dynamic ceramic membrane system. The rotation speed of the ceramic membrane is controlled at 1000rpm,...

Embodiment 3

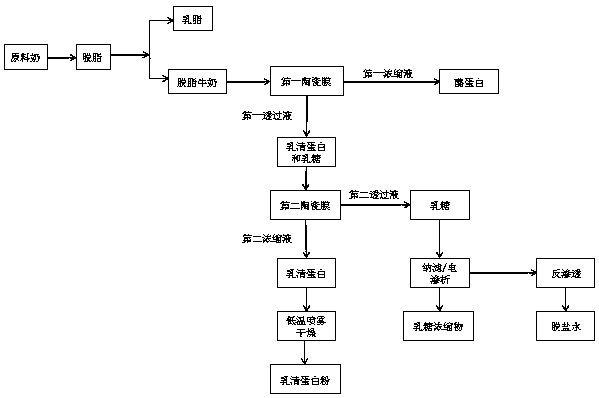

[0044] Such as figure 2 The present embodiment shown provides a membrane-integrated treatment process for milk protein fractionation, comprising the following steps:

[0045] Step 1: Preheat the raw milk first, the preheating temperature is 50°C, and then degrease the raw milk by centrifugal degreasing, the centrifugal speed is 5200r / min, the centrifugation time is 30min, and the centrifugal degreasing temperature is 55°C , to obtain skimmed milk and butterfat, and store the milkfat after separation for use as a raw material for butter or cream, and the fat content in the skimmed milk is less than 0.5%;

[0046] Step 2: Separating the skim milk through the first ceramic membrane to obtain the first concentrate and the first permeate, wherein the first concentrate contains casein, the first permeate contains whey protein and lactose, and the first The ceramic membrane adopts a dynamic ceramic membrane system, the speed of the ceramic membrane is controlled at 1200rpm, the sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com