Nitrogen-doped ultra-thin carbon nanosheet loaded monoatomic catalyst and preparation method and application thereof

A technology of carbon nanosheets and nitrogen doping, which is applied in the direction of catalyst activation/preparation, amino compound preparation, chemical instruments and methods, etc., can solve the problem of low catalyst activity, and achieve simple and easy preparation methods, good reproducibility, The effect of adjustable metal loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

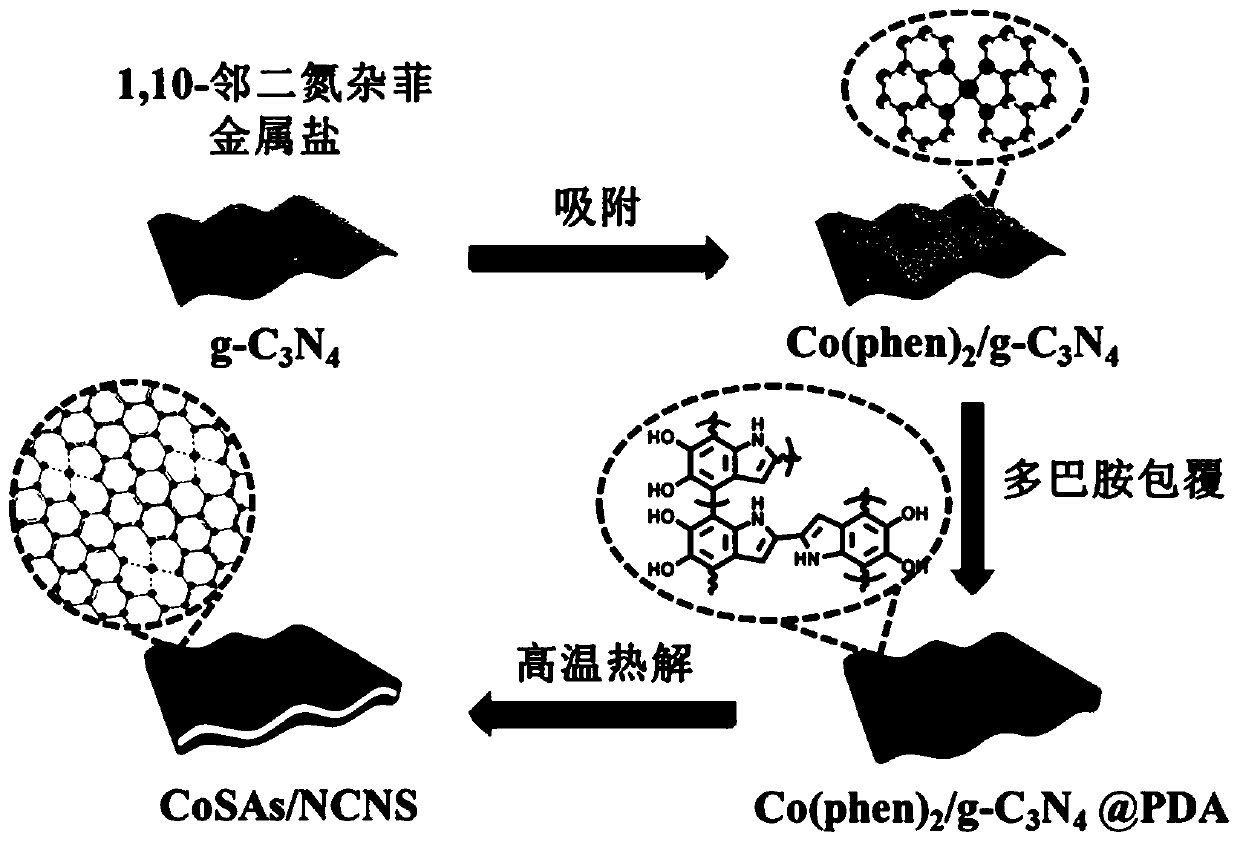

[0054] Example 1 Preparation of nitrogen-doped ultrathin carbon nanosheet-supported cobalt single-atom catalyst

[0055] 1) Weigh 12.7mg of cobalt acetate tetrahydrate and 18.4mg of 1,10-phenanthroline into a 100mL single-necked bottle, add 25mL of ethanol, and obtain Co(phen) after ultrasonication for 15 minutes 2 solution.

[0056] 2) Weigh 500mg g-C 3 N 4 Add to the aforementioned solution, sonicate for 15 minutes to make g-C 3 N 4 Disperse evenly. The one-necked bottle was placed in an 80°C oil bath to reflux for 4 hours, and then rotary evaporated at 40°C and 60 rpm for 30 minutes.

[0057] 3) The obtained solid Co(phen) 2 / g -C 3 N 4 Disperse in 150mL of methanol and sonicate at 50W for 5 minutes. Weigh 1.814g of pH buffer solution Tris (Tris) and dissolve it in 140mL of methanol, weigh 1.360g of polymerized monomer dopamine hydrochloride (DA) and dissolve it in 60mL of methanol, and dissolve the methanol of Tris and DA under stirring. The solution was added dr...

Embodiment 2

[0061] Example 2 Preparation of nitrogen-doped ultrathin carbon nanosheet-supported nickel single-atom catalyst

[0062] 1) Weigh 8.29mg of nickel acetate tetrahydrate and 18.4mg of 1,10-phenanthroline into a 100mL single-necked bottle, add 50mL of ethanol, and obtain Ni(phen) after ultrasonication for 15 minutes 3 solution.

[0063] 2) Weigh 1g g-C 3 N 4 Add to the aforementioned solution, sonicate for 30 minutes to make g-C 3 N 4 Disperse evenly. The one-necked bottle was refluxed in an oil bath at 60°C for 15 hours, and then rotary evaporated at 40°C and 60 rpm for 30 minutes.

[0064] 3) The obtained solid Ni(phen) 3 / g -C 3 N 4 Disperse in 150mL methanol and ultrasonicate for 5 minutes. Weigh 1.814g Tris and dissolve in 140mL of methanol, weigh 1.360g of dopamine hydrochloride and dissolve in 60mL of methanol, add the methanol solution of Tris and DA dropwise to the above dispersion liquid successively under stirring, and stir for 30h Afterwards, the solid was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com