Once-formed composite material board and notebook computer shell prepared from once-formed composite material board

A technology for composite material boards and notebook computers, which is applied in the fields of electrical digital data processing, synthetic resin layered products, instruments, etc., can solve the problems of low yield, easy aging, and monotonous color of die-casting parts, so as to achieve social benefits and improve Production efficiency, the effect of avoiding investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described below in conjunction with the drawings and implementation cases:

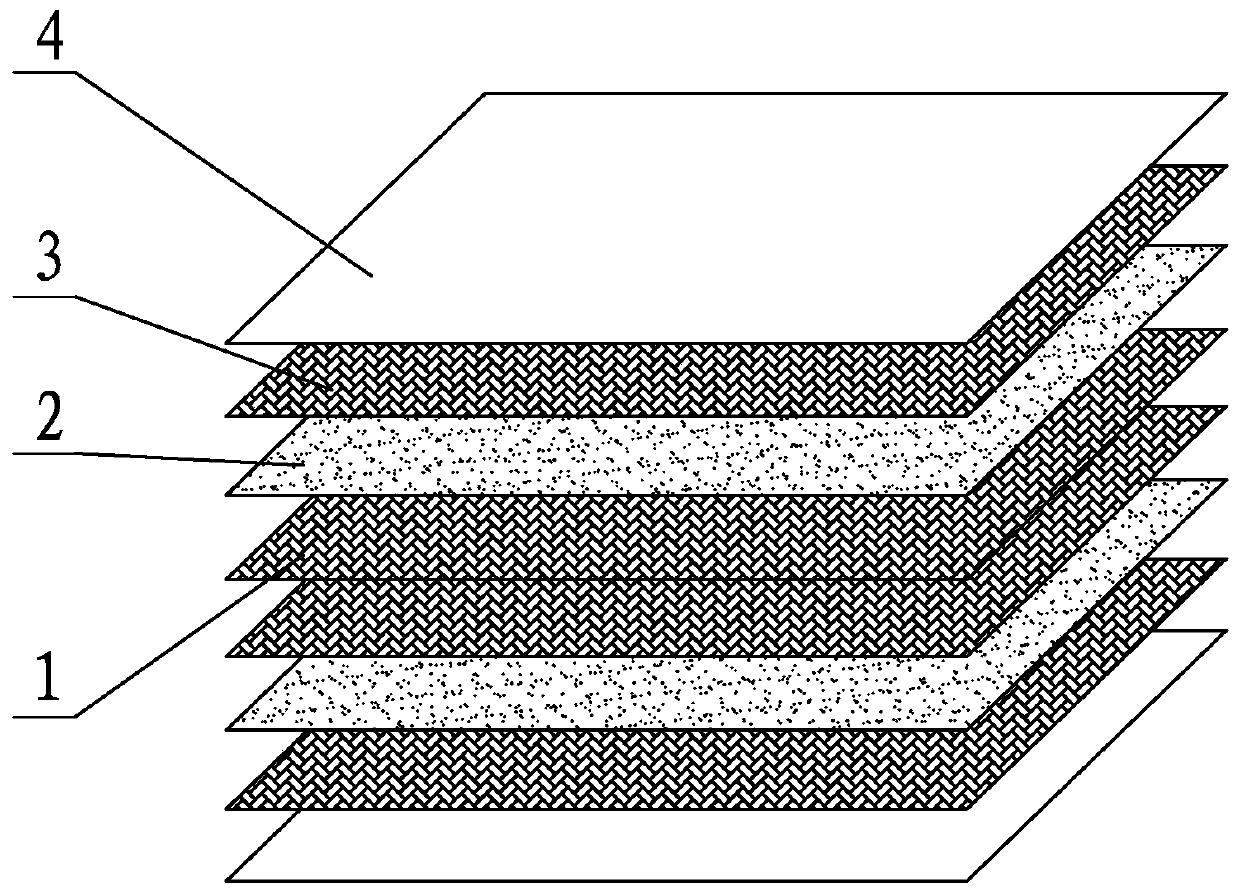

[0024] Such as figure 1 The one-shot composite material board shown includes a central woven fabric layer 1, an inner PC film layer located on both sides of the central woven fabric layer 2, a spacer woven fabric layer 3 located on both sides of the inner PC film layer 2, and a spacer woven fabric layer 3 The outer PC film layer 4 on both sides of the cloth layer 3.

[0025] In this embodiment: the composite material board is composed of two central woven fabric layers 1, an inner PC film layer located on both sides of the central woven fabric layer 1, and an interval woven layer located on both sides of the inner PC film layer 2. The cloth layer 3 and the outer PC film layer 4 on both sides of the spacer woven cloth layer 3 are composed of a total of 8 layers.

[0026] Wherein: the melting point of the outer PC film layer 4 is lower than that of the inner PC film layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com