A kind of technology of industrial production aluminum trichloride

A technology of aluminum trichloride and process, applied in the field of inorganic fine powder materials, to achieve the effects of avoiding moisture absorption and generation of hydrochloric acid mist, reducing natural heat dissipation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

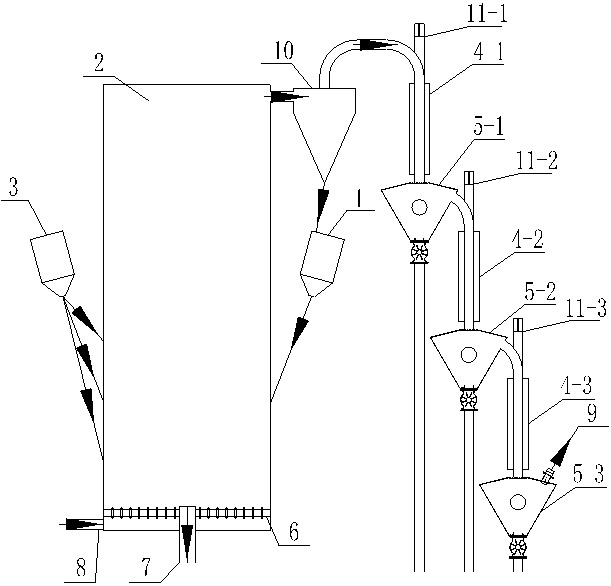

Method used

Image

Examples

Embodiment 1

[0033] a. Preheating: Add 160 parts by weight of reaction raw material alumina with a particle size of 60~150 μm and 80 parts by weight of reaction raw material petroleum coke with a particle size of 100~150 μm, respectively, through their respective belt scales. The pre-mixing silo, the mixture is quantitatively fed to the electric induction heating furnace through the discharge valve, and the feeding amount of the electric induction heating furnace is calculated by two belt scales and the pre-mixing silo weighing instrument, the pre-mixing silo and the electric induction heating The furnace is sealed with the outside world, and the nitrogen is continuously ventilated, and the nitrogen gas is replaced during the start-up. After the start-up, the nitrogen gas maintains a certain pressure to prevent the chlorine gas from returning to the chlorination furnace. The mixture is heated to 1000°C by an electric induction heating furnace. Considering that the chlorination furnace as a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com