Method for recovering methyl lactate by using supported ionic liquid as catalyst for alcoholysis of waste polylactic acid

A technology of ionic liquid and methyl lactate, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of large amount of ionic liquid, low purity, corrosion Equipment and other issues, to achieve good economic and environmental benefits, simple recycling process, to overcome the effect of corrosion equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

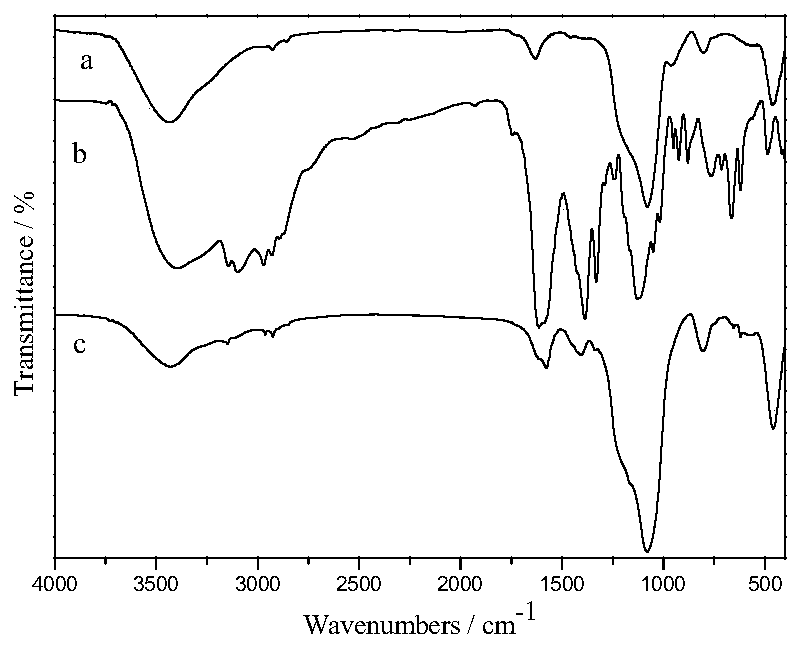

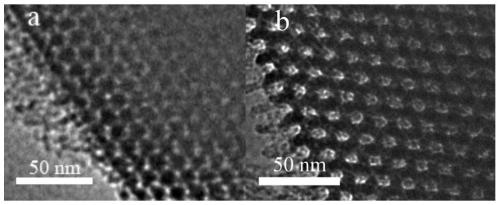

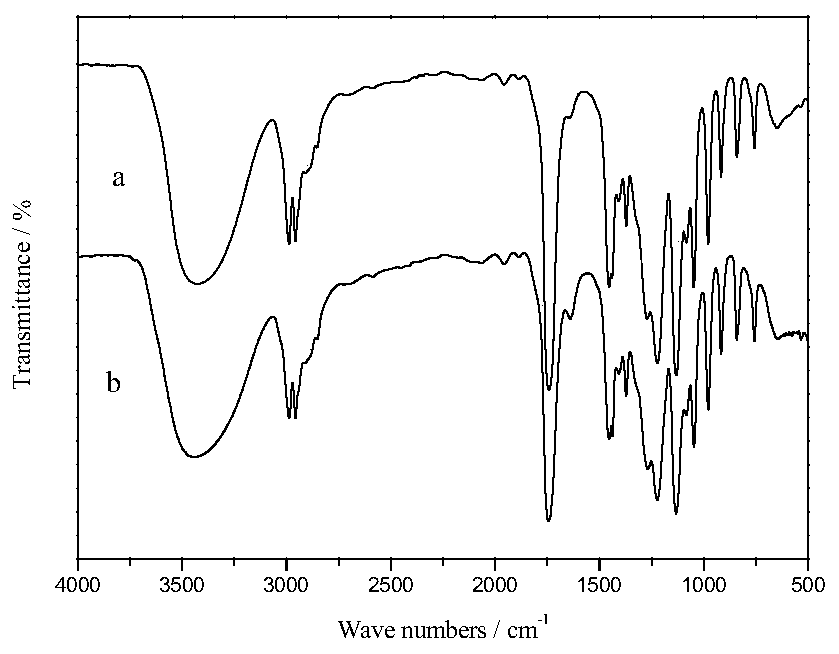

Image

Examples

Embodiment 1

[0031] Catalyst preparation

[0032] (1) Preparation of [tespmim][Cl]

[0033] Put the refined 0.1mol N-methylimidazole in a 250mL three-necked round-bottomed flask, add 0.14mol 3-chloropropyltriethoxysilane (CPTES) dropwise under an ice-water bath, and stir the reaction at room temperature for 1.0h after the dropwise reaction, in N 2Under the atmosphere, heat, stir and reflux at 80°C for 72 hours, transfer the colorless viscous liquid to a 250mL separatory funnel while hot, wash the product with anhydrous ether (10mL×3) for several times to remove unreacted substances, pour the ether layer, the lower thick liquid was transferred to a 250mL single-necked flask, ether was removed by rotary evaporation, and vacuum-dried for 4.0h to obtain a light yellow viscous liquid [tespmim][Cl] with a yield of 91.4%.

[0034] (2) Preparation of [tespmim][OAc]

[0035] Put 0.07mol solid potassium acetate in a 100mL single-necked flask, add 30g of absolute ethanol, stir to dissolve to form ...

Embodiment 2

[0050] The experimental conditions and steps were the same as in Example 1, except that the reaction temperature was changed to 125° C., the conversion rate of PLA was 100%, and 5.55 g of methyl lactate was obtained with a yield of 96.0%.

Embodiment 3

[0052] Experimental condition and step are with embodiment 1, just with 0.04g catalyst [tespmim][OAc]-Zn(OAc) 2 / SBA was changed to 0.06g, the conversion rate of PLA was 100%, and 5.56g of methyl lactate was obtained, with a yield of 96.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com