Environment-friendly antibacterial sponge and preparation method thereof

A sponge and environmental protection technology, applied in the field of sponge products, can solve the problems of difficult degradation of artificial polymers, environmental pollution, and large pollution, and achieve excellent foaming effect, good sterilization effect, and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

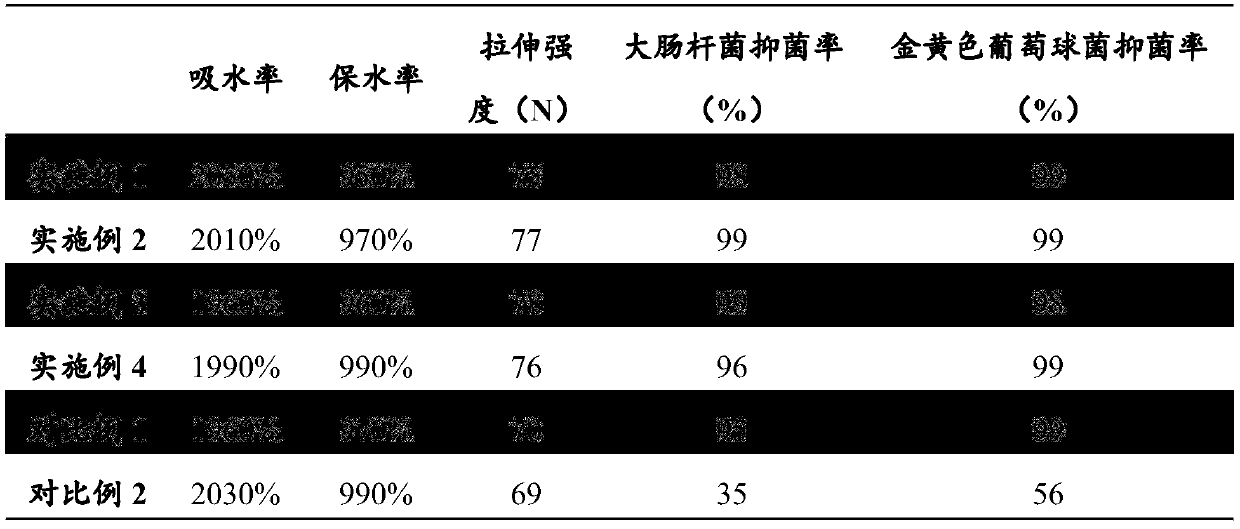

Examples

Embodiment 1

[0032] Preparation of S1, nanometer Ag-Zn / chitosan antibacterial agent:

[0033] 1) Dissolve 17gAgNO3 and 136gZnCl2 in deionized water, then add 150gPVP and mix them. After the sample is completely dissolved, place it in a microwave oven and heat it for 10min to obtain a mixed solution;

[0034] 2) Weigh 200g of chitosan and add it to the mixed solution prepared in step 1), after ultrasonication for 10min, filter, and vacuum-dry at 250°C to obtain the micronano Ag-Zn / chitosan antibacterial material;

[0035] S2, the preparation of environment-friendly antibacterial sponge:

[0036] 1) Dissolve 60g of nanocellulose material in 100mL of dilute acetic acid solution, then add dropwise 0.1N sodium hydroxide solution until the pH value of the solution is 8.0, precipitate and filter to obtain a gel solution;

[0037] 2) the nanocellulose gel solution that step 1) is obtained is diluted to the gel aqueous solution that mass fraction is 10%, and 45g guar gum hydroxypropyl trimethyl am...

Embodiment 2

[0042] Preparation of S1, nanometer Ag-Zn / chitosan antibacterial agent:

[0043]1) Dissolve 17gAgNO3 and 203gZnCl2 in deionized water, then add 280gPVP and mix them. After the sample is completely dissolved, place it in a microwave oven and heat it for 10min to obtain a mixed solution;

[0044] 2) Weigh 500g of chitosan and add it to the mixed solution prepared in step 1), after ultrasonication for 10min, filter, and vacuum-dry at 250°C to obtain the micronano Ag-Zn / chitosan antibacterial material;

[0045] S2, the preparation of environment-friendly antibacterial sponge:

[0046] 1) Dissolve 65g of nanocellulose material in 100mL of dilute acetic acid solution, then add dropwise 0.1N sodium hydroxide solution until the pH value of the solution is 7.5, precipitate and filter to obtain a gel solution;

[0047] 2) the nanocellulose gel solution that step 1) is obtained is diluted to the gel aqueous solution that mass fraction is 10%, and 35g guar gum hydroxypropyl trimethyl amm...

Embodiment 3

[0052] Preparation of S1, nanometer Ag-Zn / chitosan antibacterial agent:

[0053] 1) Weigh 17gAgNO3 and 136gZnCl2 and dissolve them in deionized water, then add 200gPVP and mix them. After the samples are completely dissolved, place them in a microwave oven and heat them for 10min to obtain a mixed solution;

[0054] 2) Weigh 300g of chitosan and add it to the mixed solution prepared in step 1), after ultrasonication for 10min, filter, and vacuum dry at 250°C to obtain a micronano Ag-Zn / chitosan antibacterial material;

[0055] S2, the preparation of environment-friendly antibacterial sponge:

[0056] 1) Dissolve 70g of nanocellulose material in 100mL of dilute acetic acid solution, then add dropwise 0.1N sodium hydroxide solution until the pH value of the solution is 8.0, precipitate and filter to obtain a gel solution;

[0057] 2) the nanocellulose gel solution that step 1) is obtained is diluted to the gel aqueous solution that mass fraction is 10%, and 30g guar gum hydroxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com