Soft moisture-absorbing curly fiber easy to dye and preparation method thereof

A crimped fiber and softening technology is applied in the field of soft, moisture-absorbing and dyeable crimped fibers and their preparation. The invention can solve the problems of low moisture absorption rate, poor dyeability, and poor fiber softness, and achieve easy curling, easy dyeing and low operation difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

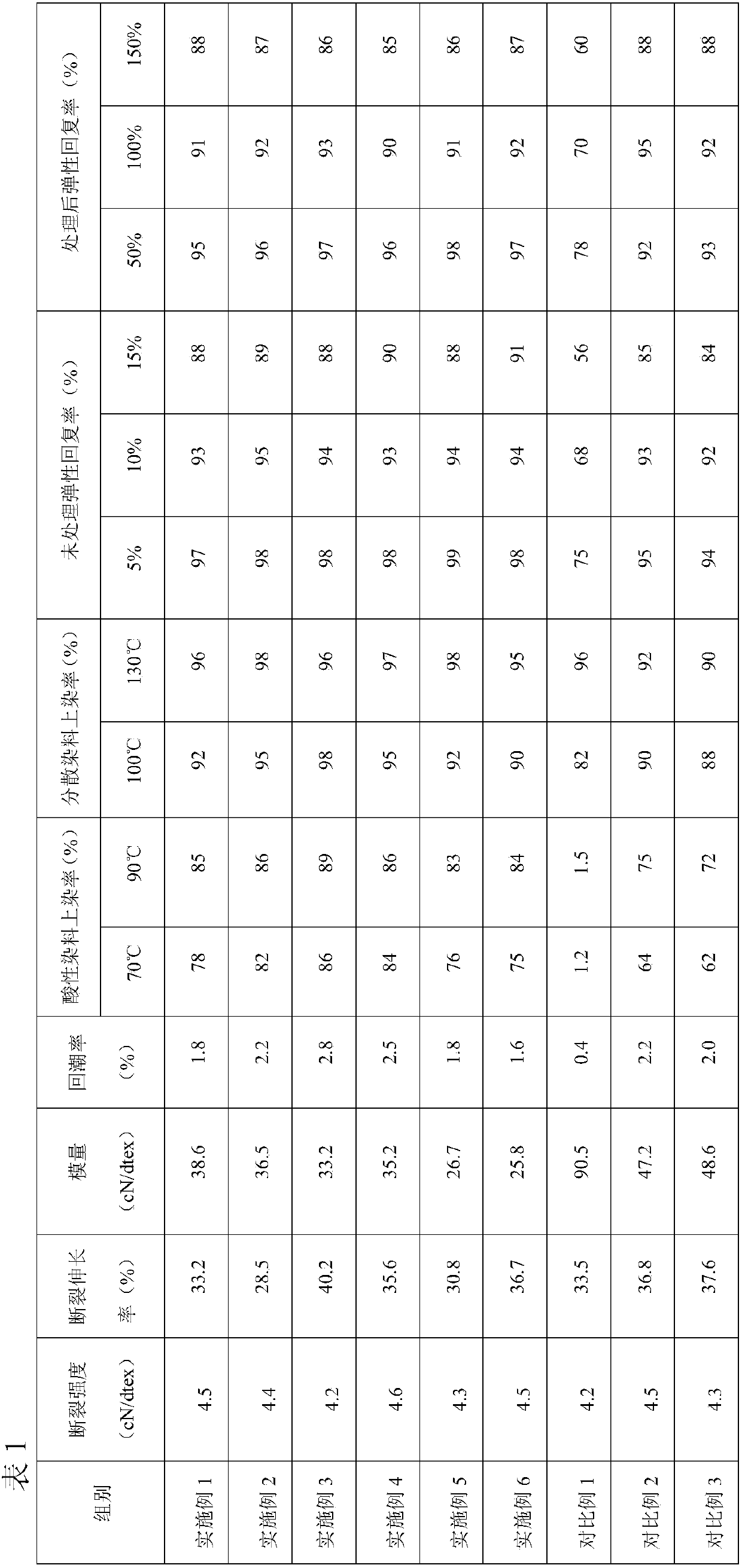

Examples

Embodiment 1

[0055] The preparation method of the soft, hygroscopic and easy-to-dye curly fibers of the present embodiment is as follows:

[0056] 1) The polyamide 56 melt and the polyethylene terephthalate melt are merged in the spinning assembly in the spinning box through their respective melt pipes, sprayed out through the eccentric composite spinneret, and cooled. form spun silk;

[0057] Among them, the skin-core component ratio is accurately adjusted by a metering pump, the polyamide 56 content of the skin layer is 20wt%, and the polyethylene terephthalate content of the core layer is 80wt%;

[0058] Wherein, the temperature of the spinning box is 285° C., and the pressure of the spinning assembly of the spinning box is 15 MPa.

[0059] 2) post-processing the above-mentioned as-spun silk to obtain soft, hygroscopic and easy-to-dye curly fibers;

[0060] Among them, the cooling treatment is side blowing cooling, the wind speed of the side blowing is 0.6m / s, the temperature of the s...

Embodiment 2

[0072] The preparation method of the soft, hygroscopic and easy-to-dye curly fibers of the present embodiment is as follows:

[0073] 1) The polyamide 56 melt and the polytrimethylene terephthalate melt are combined in the spinning box through their respective melt pipes, and then sprayed out through the eccentric composite spinneret and cooled to form a primary Silk;

[0074] Among them, the skin-core component ratio is accurately adjusted by a metering pump, the polyamide 56 content of the skin layer is 30wt%, and the polyethylene terephthalate content of the core layer is 70wt%;

[0075] Wherein, the temperature of the spinning box is 290° C., and the pressure of the spinning assembly of the spinning box is 17 MPa.

[0076] 2) post-processing the above-mentioned as-spun silk to obtain soft, hygroscopic and easy-to-dye curly fibers;

[0077] Wherein, the cooling treatment is side blowing cooling, the wind speed of the side blowing is 0.5m / s, the temperature of the side blo...

Embodiment 3

[0083] The preparation method of the soft, hygroscopic and easy-to-dye curly fibers of the present embodiment is as follows:

[0084] 1) The polyamide 56 melt and the polyethylene terephthalate melt are merged in the spinning assembly in the spinning box through their respective melt pipes, sprayed out through the positive core composite spinneret, and cooled. form spun silk;

[0085] Wherein, the skin-core component ratio is accurately adjusted by a metering pump, the polyamide 56 content of the skin layer is 50wt%, and the polyethylene terephthalate content of the core layer is 50wt%;

[0086] Wherein, the temperature of the spinning box is 292° C., and the spinning assembly pressure of the spinning box is 16 MPa.

[0087] 2) post-processing the above-mentioned as-spun silk to obtain soft, hygroscopic and easy-to-dye curly fibers;

[0088] Among them, the cooling treatment is side blowing cooling, the wind speed of the side blowing is 0.8m / s, the temperature of the side bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com