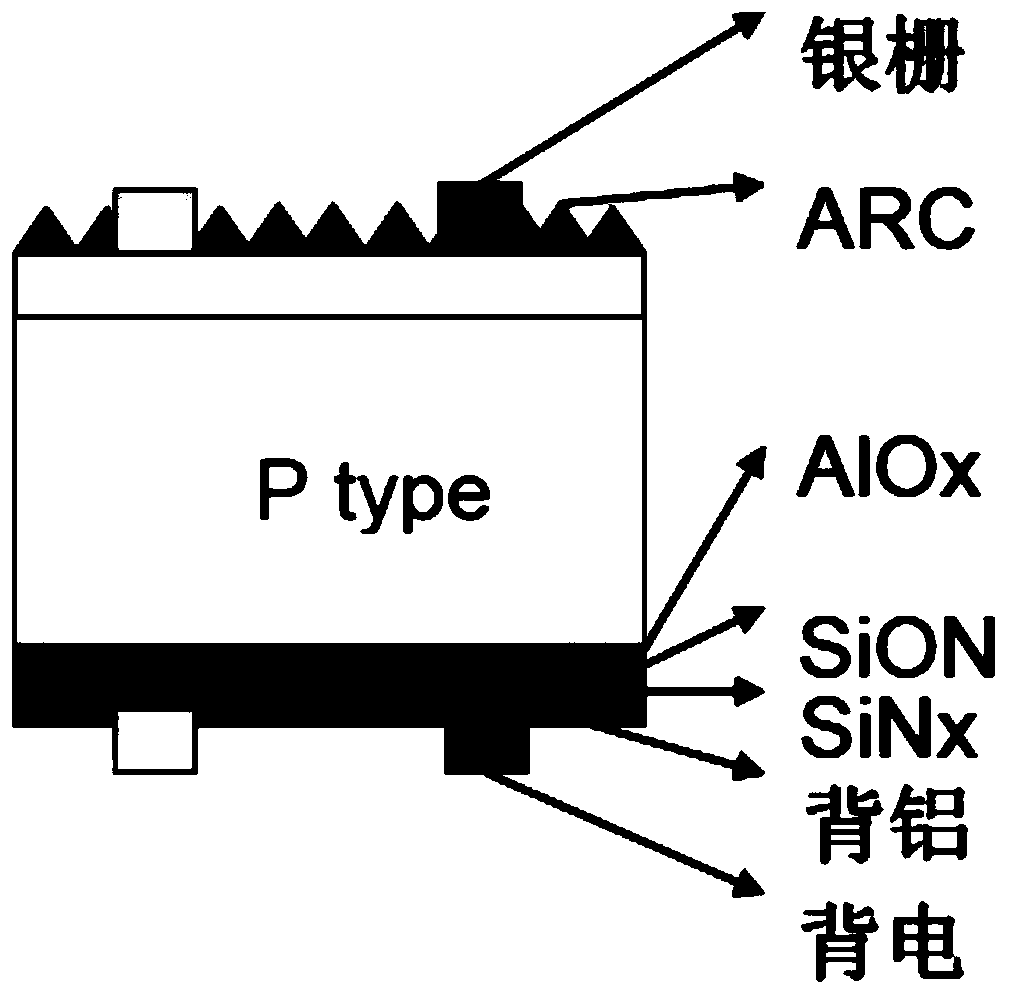

High-reliability PERC back silver conductive paste for crystalline silicon solar cell and preparation process for high-reliability PERC back silver conductive paste

A technology for solar cells and conductive pastes, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems such as difficulty in adapting to low-temperature sintering requirements, sensitivity to sintering temperature, and insufficient reliability. , to achieve the effect of improving density and soldering reliability, reliable contact, and promoting conductive network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

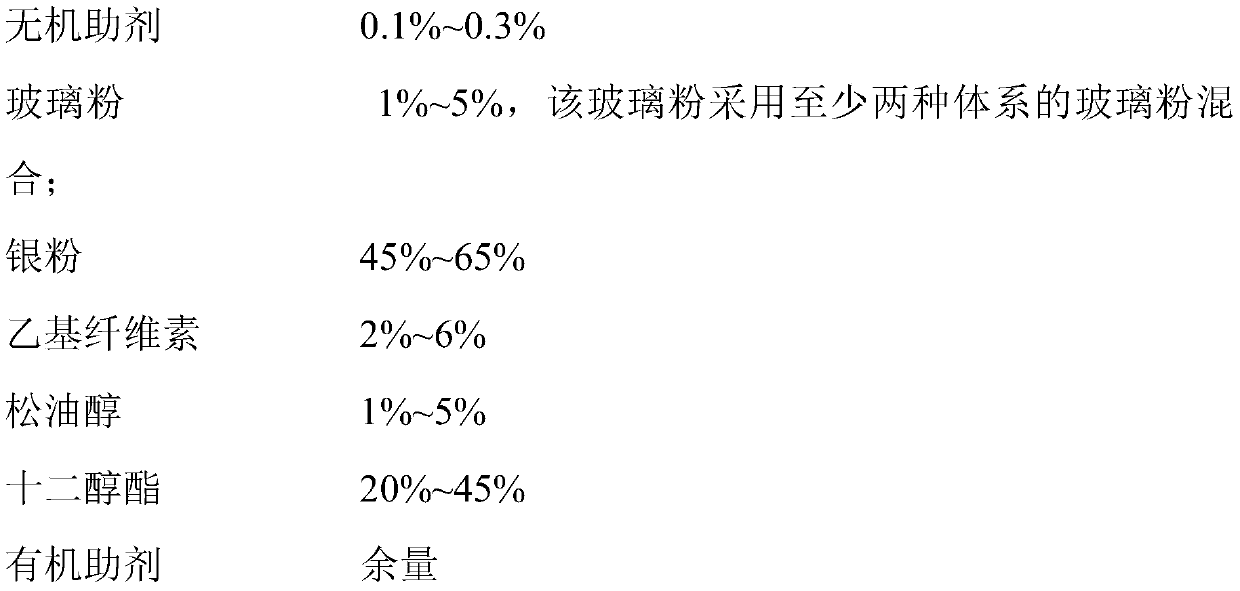

[0026] Embodiments 1 to 5: a silver conductive paste on the back of a high-reliability PERC crystalline silicon solar cell, the composition and quality of the silver conductive paste on the back is as shown in Table 1:

[0027] Table I

[0028]

[0029] Described glass powder composition is respectively:

[0030] One mole fraction of glass powder consists of 0.1 to 0.2 parts of Bi 2 o 3 , 0.01 to 0.2 parts of Na 2 O, 0.1-0.3 parts of CuO, 0.05-0.2 parts of Al 2 o 3 , 0.35~0.55 parts of SiO 2 , 0~0.2 parts of MnO 2 ;

[0031] The two mole fractions of glass powder consist of 0.2 to 0.4 parts of PbO and 0.2 to 0.5 parts of SiO 2 , 0.01~0.1 parts of Li 2 O, 0.02 to 0.3 parts of Al 2 o 3 , 0.1 to 0.15 parts of TiO 2 , 0.05~0.2 part B 2 o 3 ;

[0032] In the first to fifth implementations, the inorganic additives are nano-CuO, nano-tin powder, and nano-SiO 2 One or more combinations of

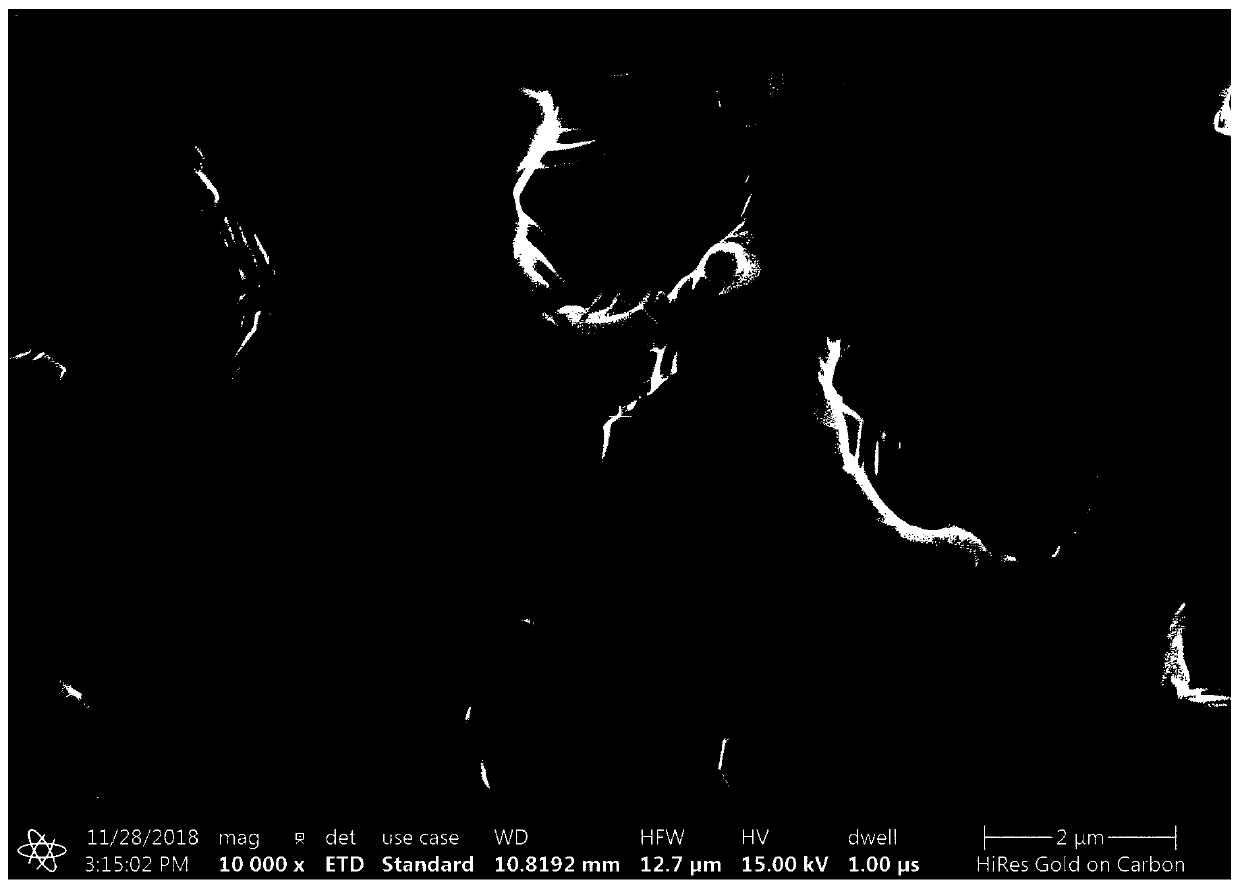

[0033] The average particle size of the conductive phase of silver powder i...

Embodiment 1

[0039] Embodiment one test electric performance is as table two:

[0040] Table II

[0041] PASTE

Embodiment 2

[0042] Embodiment two test electrical properties are as table three:

[0043] Table three

[0044] PASTE

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com