A kind of nickel selenide and ternary nickel-iron selenide composite electrocatalyst and its preparation method and application

An electrocatalyst, nickel-iron selenide technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., to achieve the effects of good stability, good stability, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Weighing of selenium powder

[0034] (1) Weigh 60 mg of selenium powder and put it into the bottom of the quartz tube.

[0035] 2. Pretreatment of nickel-iron foam

[0036] (1) The nickel foam was impregnated with 1mol / L hydrochloric acid solution, acetone solution, and absolute ethanol solution for 10 min and ultrasonically cleaned for 10 minutes, and finally cleaned three times with distilled water ultrasonically.

[0037] Preparation of 3.1mol / L KOH solution

[0038] (1) Measure about 50mL of ultrapure water and 5.61g of potassium hydroxide, dissolve them with ultrapure water and stir, after cooling, dilute to volume in a 100mL volumetric flask.

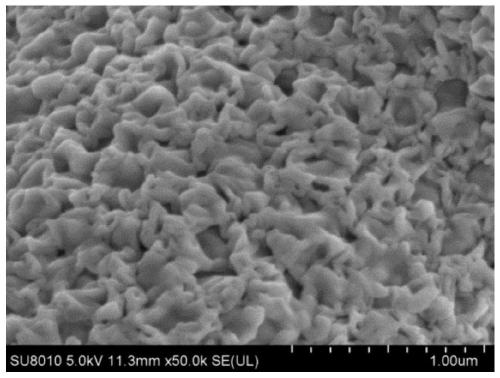

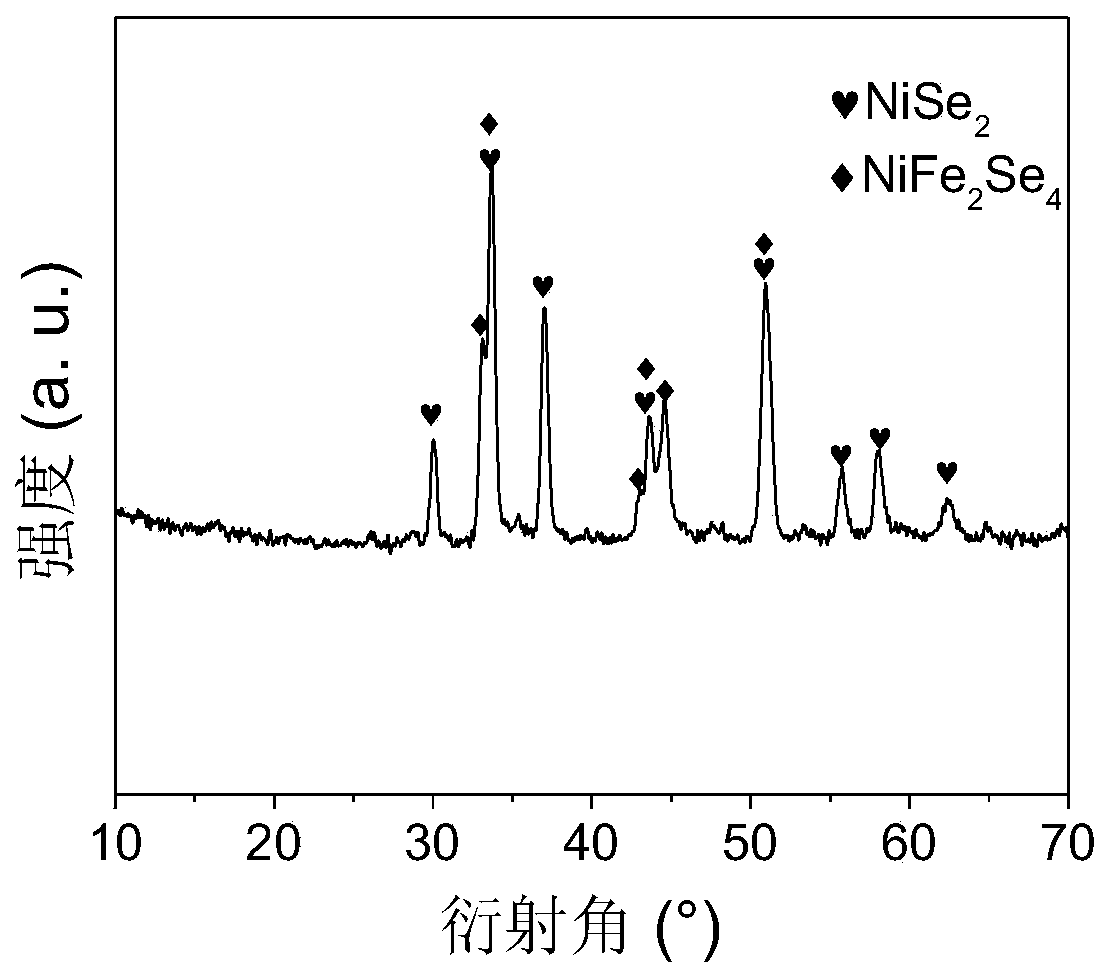

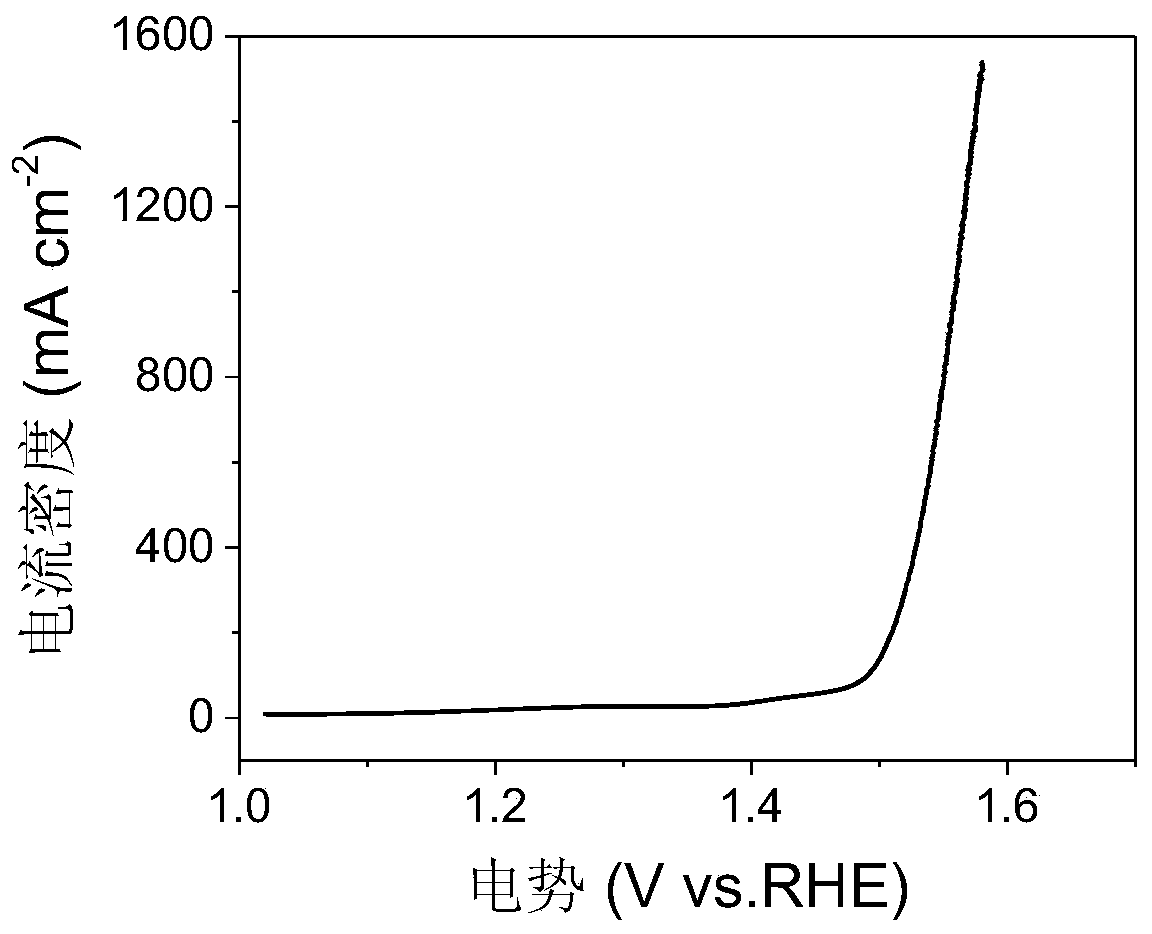

[0039] 4. In situ growth of NiSe on the surface of nickel-iron alloy foam 2 and ternary NiFe 2 Se 4 Preparation of composite electrocatalyst

[0040] (1) Put the pretreated foam nickel-iron alloy and the weighed selenium powder into the quartz tube, and vacuum seal the tube;

[0041] (2) Put the sealed quartz tube...

Embodiment 2

[0044] 1. Weighing of selenium powder

[0045] (1) Weigh 40 mg of selenium powder and put it into the bottom of the quartz tube.

[0046] 2. Pretreatment of nickel-iron foam

[0047] (1) The nickel foam was impregnated with 1mol / L hydrochloric acid solution, acetone solution, and absolute ethanol solution for 10 min and ultrasonically cleaned for 10 minutes, and finally cleaned three times with distilled water ultrasonically.

[0048] Preparation of 3.1mol / L KOH solution

[0049] (1) Measure about 50mL of ultrapure water and 5.61g of potassium hydroxide, dissolve them with ultrapure water and stir, after cooling, dilute to volume in a 100mL volumetric flask.

[0050] 4. In situ growth of NiSe on the surface of nickel-iron alloy foam 2 and ternary NiFe 2 Se 4 Preparation of composite electrocatalyst

[0051] (1) Put the pretreated foam nickel-iron alloy and the weighed selenium powder into the quartz tube, and vacuum seal the tube;

[0052] (2) Put the sealed quartz tube...

Embodiment 3

[0054] 1. Weighing of selenium powder

[0055] (1) Weigh 80 mg of selenium powder and put it into the bottom of the quartz tube.

[0056] 2. Pretreatment of nickel-iron foam

[0057] (1) The nickel foam was impregnated with 1mol / L hydrochloric acid solution, acetone solution, and absolute ethanol solution for 10 min and ultrasonically cleaned for 10 minutes, and finally cleaned three times with distilled water ultrasonically.

[0058] Preparation of 3.1mol / L KOH solution

[0059] (1) Measure about 50mL of ultrapure water and 5.61g of potassium hydroxide, dissolve them with ultrapure water and stir, after cooling, dilute to volume in a 100mL volumetric flask.

[0060] 4. In situ growth of NiSe on the surface of nickel-iron alloy foam 2 and ternary NiFe 2 Se 4 Preparation of composite electrocatalyst

[0061] (1) Put the pretreated foam nickel-iron alloy and the weighed selenium powder into the quartz tube, and vacuum seal the tube;

[0062] (2) Put the sealed quartz tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com