Reduction state platinum-rhodium reforming catalyst

A reforming catalyst, catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalyst, naphtha catalytic reforming, etc. Harm can not be completely solved and other problems, to achieve the effect of good dispersion state, saving catalyst treatment procedures, and protecting high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

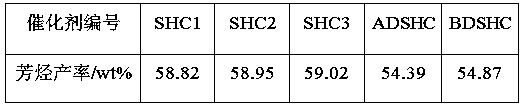

Examples

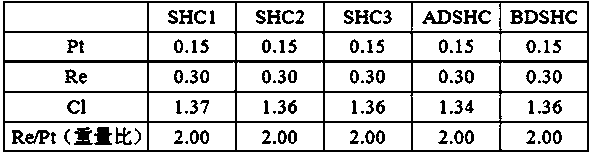

Embodiment 1

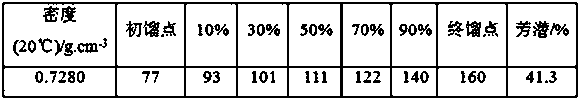

[0041] (1) Preparation of oxidized platinum-rhenium reforming catalyst: take 300g of SB powder aluminum hydroxide (Al 2 o 3 Aluminum powder, dry basis content 75%), add 21mL of nitric acid with a concentration of 65%, 150mL of deionized water, and 2g of scallop powder, knead and extrude, and dry at 110°C for 4 hours to obtain a dry molded product to obtain alumina Carrier: put the above-mentioned alumina carrier in a hydrothermal treatment furnace, raise the temperature to 140°C, add 150mL of hydrochloric acid aqueous solution with a concentration of 10%, keep the temperature at a constant temperature for 2 hours under a pressure of 0.2MPa, then raise the temperature to 350°C, and add a concentration of 2% 150mL hydrochloric acid aqueous solution, under the pressure of 0.2MPa, constant temperature for 0.5 hours, then placed in a high-temperature furnace, heated to 550 ° C for 4 hours to obtain the modified alumina carrier, its macroscopic physical properties are listed in Tabl...

Embodiment 2

[0048] In addition to changing the hydrogen chloride content in the hydrogen to 1.90 μL / L in step (2), hydrogen chloride accounts for 2.0m% of the theoretical total water in the system; other operations are the same as in Example 1, and the reduced platinum-rhenium reforming catalyst SHC2 is obtained. The content of each element is shown in Table 2.

Embodiment 3

[0050] In addition to changing the hydrogen chloride content in the hydrogen to 2.85 μL / L in step (2), hydrogen chloride accounts for 3.0m% of the theoretical total water in the system; other operations are the same as in Example 1, and the reduced platinum-rhenium reforming catalyst SHC3 is obtained. The content of each element is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com