Zn-Ge-X ternary biomedical material and preparation method thereof

A biomedical material and mass fraction technology, which is applied in the field of Zn-Ge-X ternary biomedical materials and their preparation, achieves the effects of excellent mechanical properties, good blood compatibility, and a simple and controllable preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

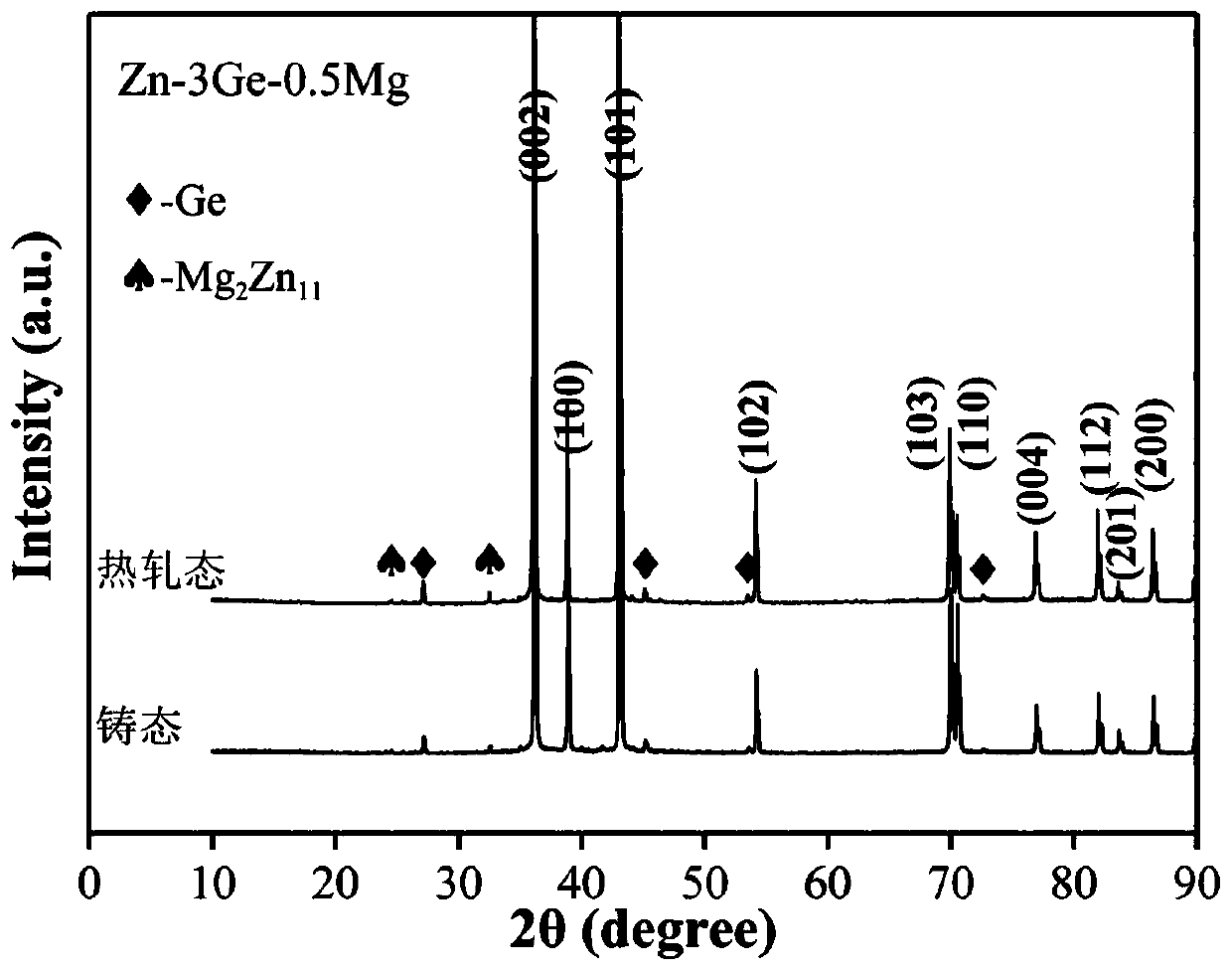

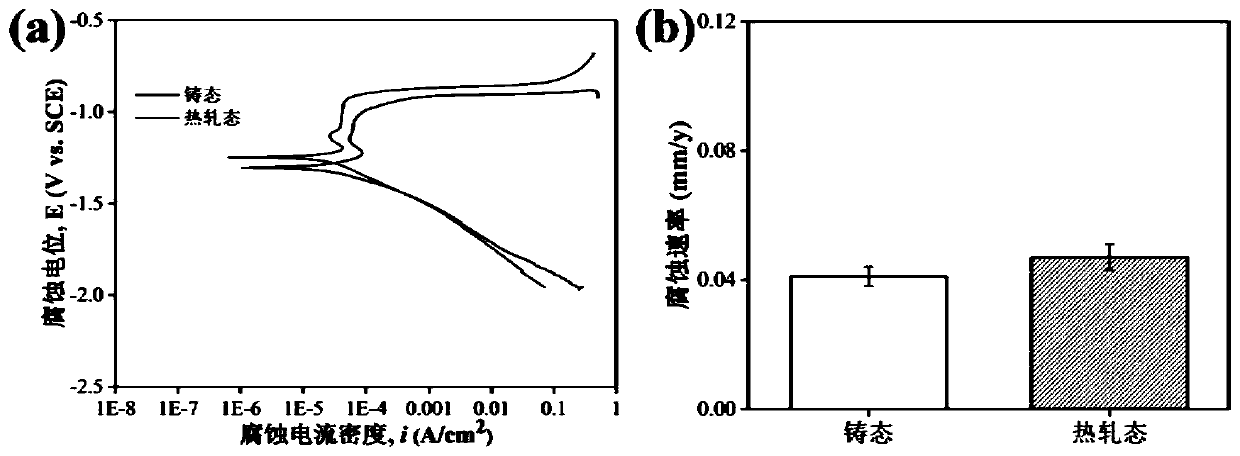

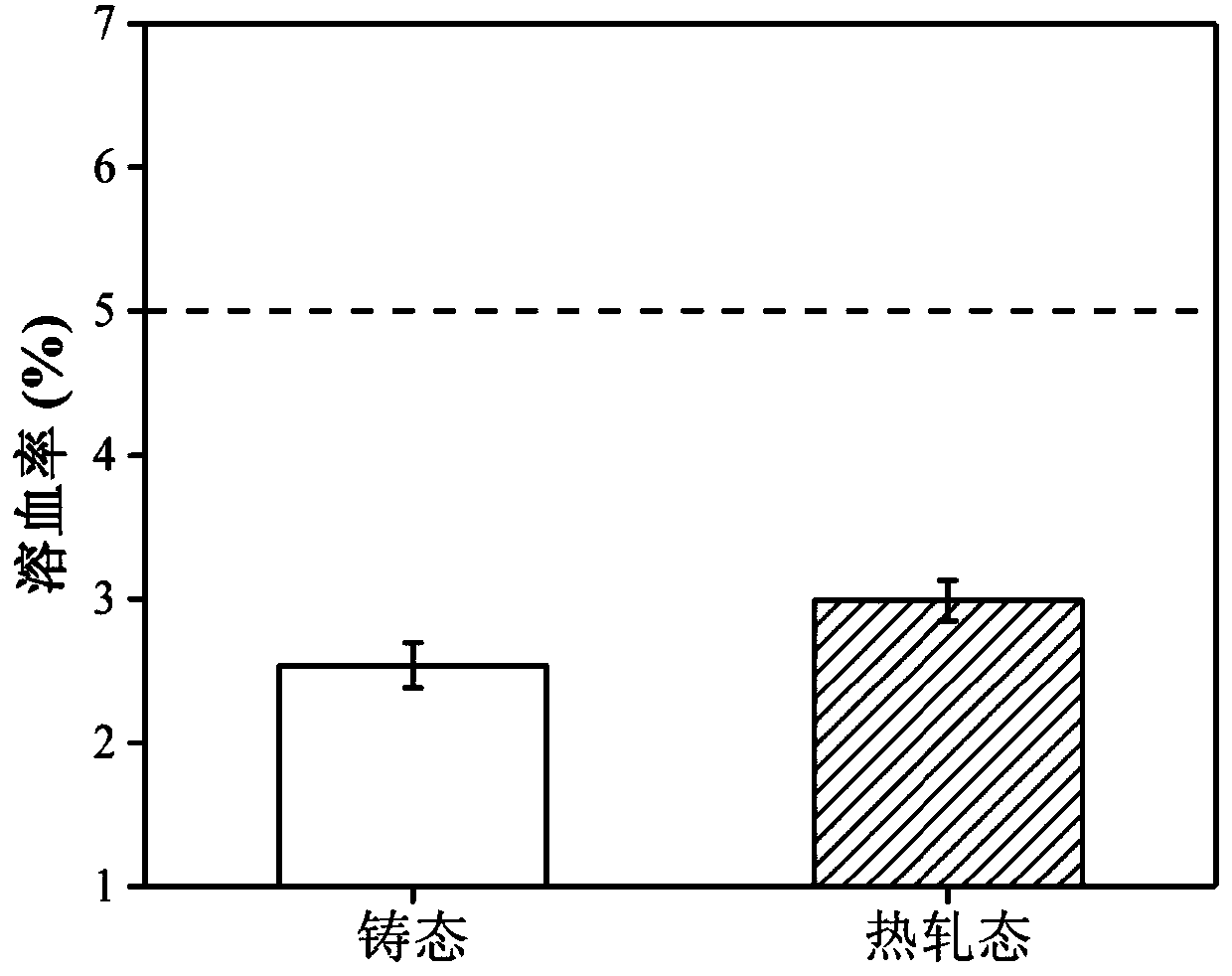

Embodiment 1

[0040] First, pure Zn ingot (99.99wt.%), single crystal Ge (99.999wt.%), pure Mg ingot (99.95wt.%) were used as raw materials, and according to the composition of the three elements in the ternary Zn-3Ge-0.5Mg alloy composition The mass ratio is weighed. Then put pure zinc into a graphite crucible and place it in a pit furnace for melting. 2 Under the protection of the atmosphere, heat to 550°C for smelting. After the pure zinc is completely melted, add single crystal Ge, and press the single crystal Ge into the liquid surface to avoid the phenomenon that Ge cannot be melted due to floating up. After the single crystal germanium is fully melted, the pure Mg ingot is pressed into the liquid surface, and the temperature is adjusted to 540°C. After the pure Mg ingot is completely melted, continue to stir with a graphite rod for 2 minutes, and then carry out slag removal after standing for 5 minutes, and lower the pouring temperature to 520°C. Finally, it is poured into a steel ...

Embodiment 2

[0057] Firstly, pure Zn ingot (99.99wt.%), single crystal Ge (99.999wt.%), pure Cu wire (99.99wt.%) were used as raw materials, and according to the composition of three elements in the ternary Zn-3Ge-0.5Cu alloy The mass ratio is weighed. Then put pure zinc into a graphite crucible and place it in a pit furnace for melting. 2 Under the protection of the atmosphere, heat to 590°C for smelting. After the pure zinc is completely melted, add single crystal Ge, and press the single crystal Ge into the liquid surface to avoid the phenomenon that Ge floats up and cannot be melted. After the single crystal germanium is fully melted, press the pure Cu wire under the liquid surface, and adjust the temperature to 550°C. After the pure Cu wire is completely melted, continue to stir with a graphite rod for 5 minutes, and then carry out slag removal after standing for 10 minutes, and lower the pouring temperature to 520°C. Finally, it is poured into a steel mold preheated to 220°C, and a...

Embodiment 3

[0062] First, pure Zn ingot (99.99wt.%), single crystal Ge (99.999wt.%), pure Fe powder (99.99wt.%) are used as raw materials, and according to the composition of three elemental elements in the ternary Zn-2Ge-0.7Fe alloy composition The mass ratio is weighed. Then put pure zinc into a graphite crucible and place it in a pit furnace for melting. 2 Under the protection of the atmosphere, heat to 640°C for smelting. After the pure zinc is completely melted, add single crystal Ge, and press the single crystal Ge into the liquid surface to avoid the phenomenon that Ge floats up and cannot be melted. After the single crystal germanium is fully melted, the pure Fe powder is pressed into the liquid surface, and the temperature is adjusted to 600°C. After the pure Fe powder is completely melted, continue to stir with a graphite rod for 2 minutes, and then carry out slag removal after standing for 5 minutes, and lower the pouring temperature to 550°C. Finally, it is poured into a ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Vickers hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com