A kind of highly active, anti-carbon deposition methane dry gas reforming catalyst and preparation method thereof

A technology for dry gas reforming and carbon deposition of methane, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Stacking, reduction of active metal utilization rate, reduction of material specific surface area, etc., to achieve the effect of improving the utilization rate of raw materials and the yield of composite materials, reducing the rate of carbon deposition, and reducing the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

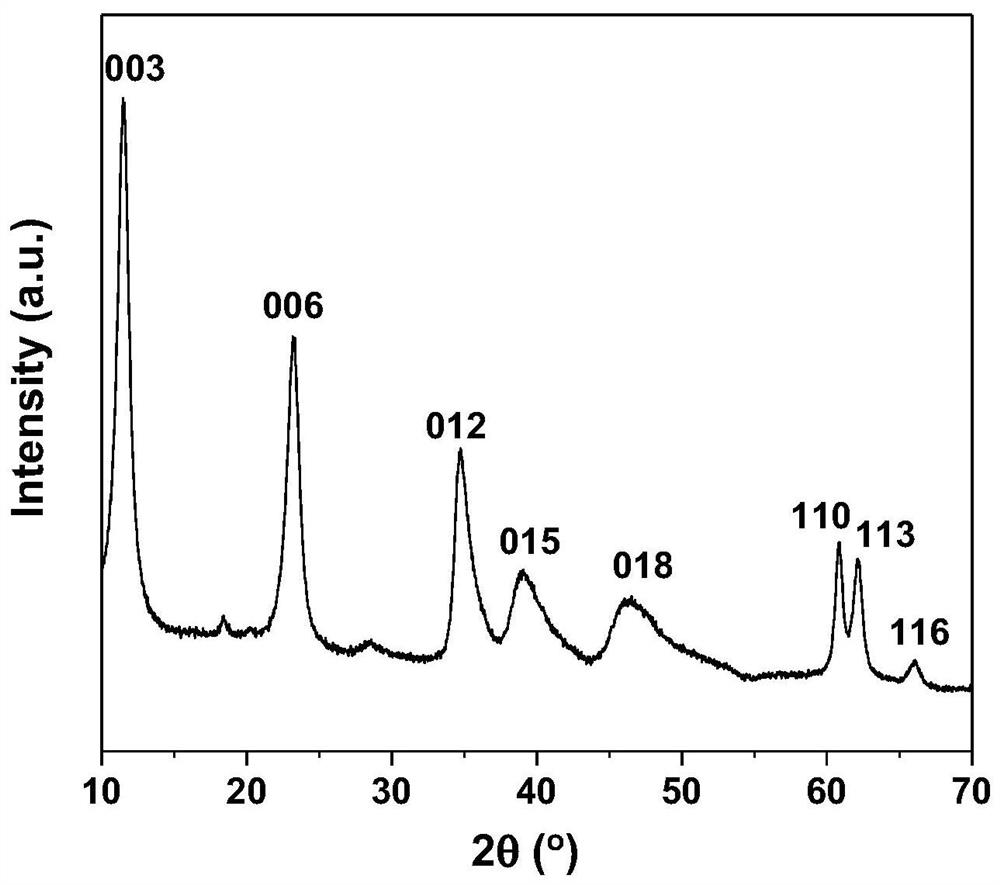

[0034] Preparation of Ni-Mg-Al nanosheets: take 5.0mmol of Ni(NO 3 ) 2 ·6H 2 O, 40.0mmol of Mg(NO 3 ) 2 ·6H 2 O and 15.0mmol of Al(NO 3 ) 3 9H 2 O, dissolved in 50 mL deionized water to make solution A. Prepare another 200mL NaOH solution with a concentration of 0.13mol / L, which is called solution B. Put solution B in a water bath at 30°C, add solution A into it under vigorous stirring, and continue stirring for 60 minutes. After filtering and washing, the precipitate was redispersed in 200 mL of deionized water, put into a hydrothermal kettle, and heated at 100°C for 16 hours to obtain a nanosheet sol with a solid content of 4.0 mg / mL. Confirmed by XRD results ( figure 1 ), the material has a nanosheet structure, denoted as NMA.

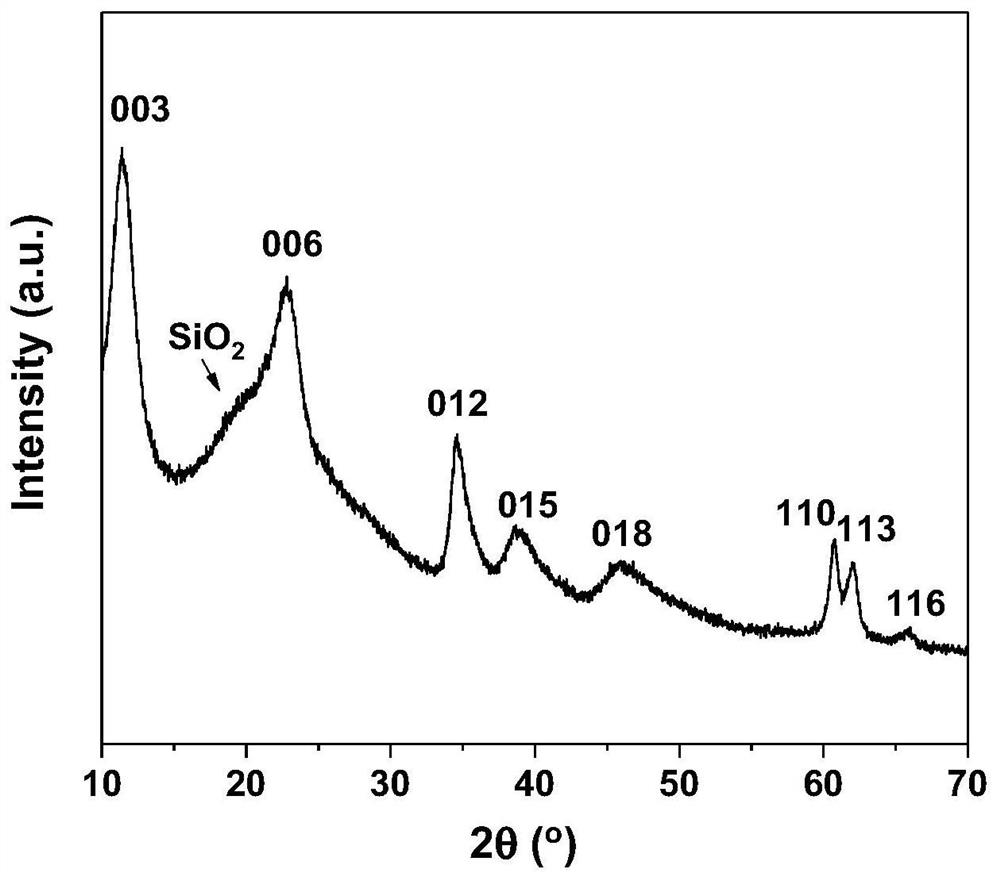

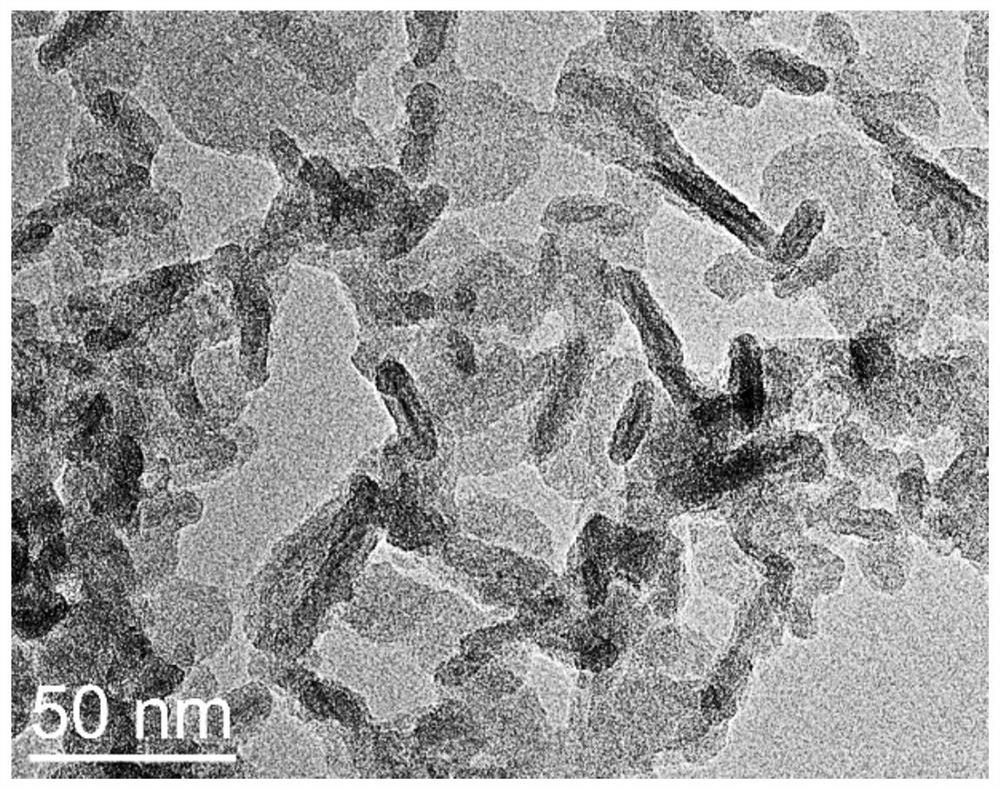

[0035] Preparation of coated Ni-Mg-Al@SiO 2 Composite material: Measure 90 mL of nanosheet sol, add 7 mL of ammonia water, and 1.30 mL of tetraethyl orthosilicate (TEOS), and stir and react in a water bath at 30°C for 16 hours. The prod...

Embodiment 2

[0038] Example 1 was repeated, but the amount of TEOS added was 0.65 mL to obtain a composite material NMAS-2 with a sheet-coated structure, and the thickness of the coating layer was 2 nm. After reduction and activation, NMAS-2-R, a highly active and carbon-resistant methane dry gas reforming catalyst, was obtained.

Embodiment 3

[0040] Example 1 was repeated, but the amount of TEOS added was 2.60 mL to obtain a composite material NMAS-3 with a sheet-coated structure, and the thickness of the coating layer was 7 nm. After reduction and activation, NMAS-3-R, a highly active and carbon-resistant methane dry gas reforming catalyst, was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com