Photocatalyst, preparation method and application thereof

A photocatalyst and fossil technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of limited carrier separation efficiency, save time and energy, improve separation efficiency, The possible effect of reducing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

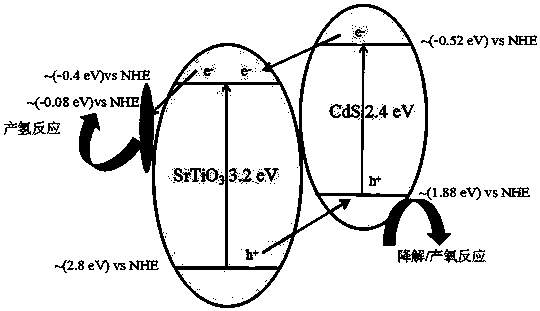

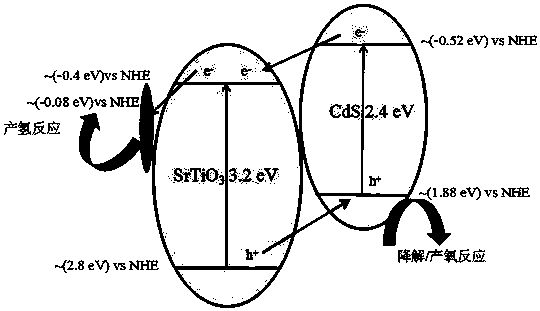

Method used

Image

Examples

Embodiment 1

[0037] Add 1 mmol tetrabutyl titanate to 25 mL ethylene glycol and stir evenly, gradually add 5 mL 0.2 mol / L strontium nitrate solution, add 5 mL 2 mol / L sodium hydroxide solution, stir for 10 min, add 1 mL, 2 mg / mL graphene oxide solution, ultrasonic 30 min, to obtain graphene oxide doped strontium titanate-graphene oxide precursor, then add 5 mL, 0.01 mol / L cadmium acetate solution, add 5 mL of 0.01 mol / L sodium sulfide solution was stirred for 2 h, then transferred to the reactor, and reacted at 180 °C for 12 h to obtain SrTiO 3 - Graphene - CdS. The SrTiO obtained by this embodiment 3 - The degradation rate of graphene-CdS sample was 81% in 2 h, and the obtained SrTiO 3 - 701.9 μmol∙g of hydrogen produced by graphene-CdS sample after 4 hours of hydrogen production experiment -1 ∙ h -1 .

Embodiment 2

[0039] Add 2.5 mmol tetrabutyl titanate to 25 mL ethylene glycol and stir evenly, gradually add 5 mL, 0.5 mol / L strontium nitrate solution, add 5 mL, 5 mol / L sodium hydroxide solution, and stir for 10 min , add 5 mL, 2 mg / mL of graphene oxide solution, ultrasonic for 30 min to obtain the strontium titanate-graphene oxide precursor with graphene oxide doping amount, and then add 5 mL, 0.2 mol / L chlorine Cadmium chloride solution, add 5 mL of 0.2 mol / L thiourea solution, stir for 2 h, then transfer to a reaction kettle for 16 h at 180 °C to obtain SrTiO 3 - Graphene - CdS. The SrTiO obtained by this embodiment 3 -The degradation rate of graphene-CdS sample was 92% in 2 h, and the obtained SrTiO 3 - 492.6 μmol∙g of hydrogen produced by graphene-CdS sample after 4 hours of hydrogen production experiment -1 ∙ h -1 .

Embodiment 3

[0041] Add 5 mmol tetrabutyl titanate to 25 mL ethylene glycol and stir evenly, gradually add 5 mL, 0.5 mol / L strontium nitrate solution, add 5 mL, 5 mol / L sodium hydroxide solution, and stir for 10 min , adding 8 mL, 2 mg / mL graphene oxide solution, ultrasonication for 30 min, to obtain strontium titanate-graphene oxide precursors with different amounts of graphene oxide doping, and then adding 5 mL 1 mol / L nitric acid Cadmium solution, add 5 mL of 1 mol / L L-cysteine solution, stir for 2 h, then transfer to a reaction kettle for 36 h at 180 °C to obtain SrTiO 3 - Graphene - CdS. SrTiO obtained by Example 3 3 - The degradation rate of graphene-CdS sample was 76% in 2 h, and the obtained SrTiO 3 - 983.1 μmol∙g of hydrogen produced by graphene-CdS sample after 4 hours of hydrogen production experiment -1 ∙ h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com