A molybdenum phosphide catalyst used for gas phase selective hydrodechlorination for preparing 2,3,3,3-tetrafluoropropene

A molybdenum phosphide catalyst and selective hydrogenation technology, which is applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, dehydrohalogenation preparation, etc., can solve the problems of reduced selectivity of target products, increased reaction process costs, etc., and achieve high temperature resistance to sintering The effect of good ability and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

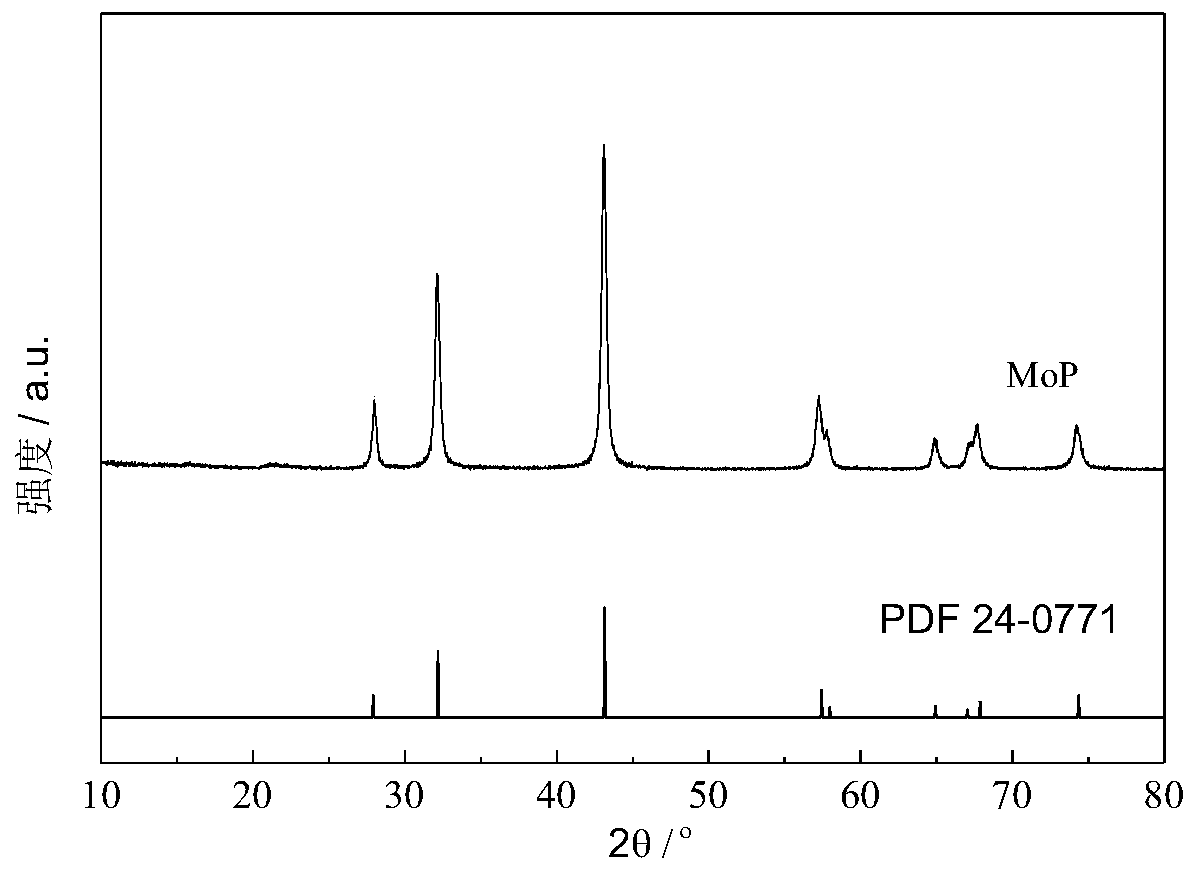

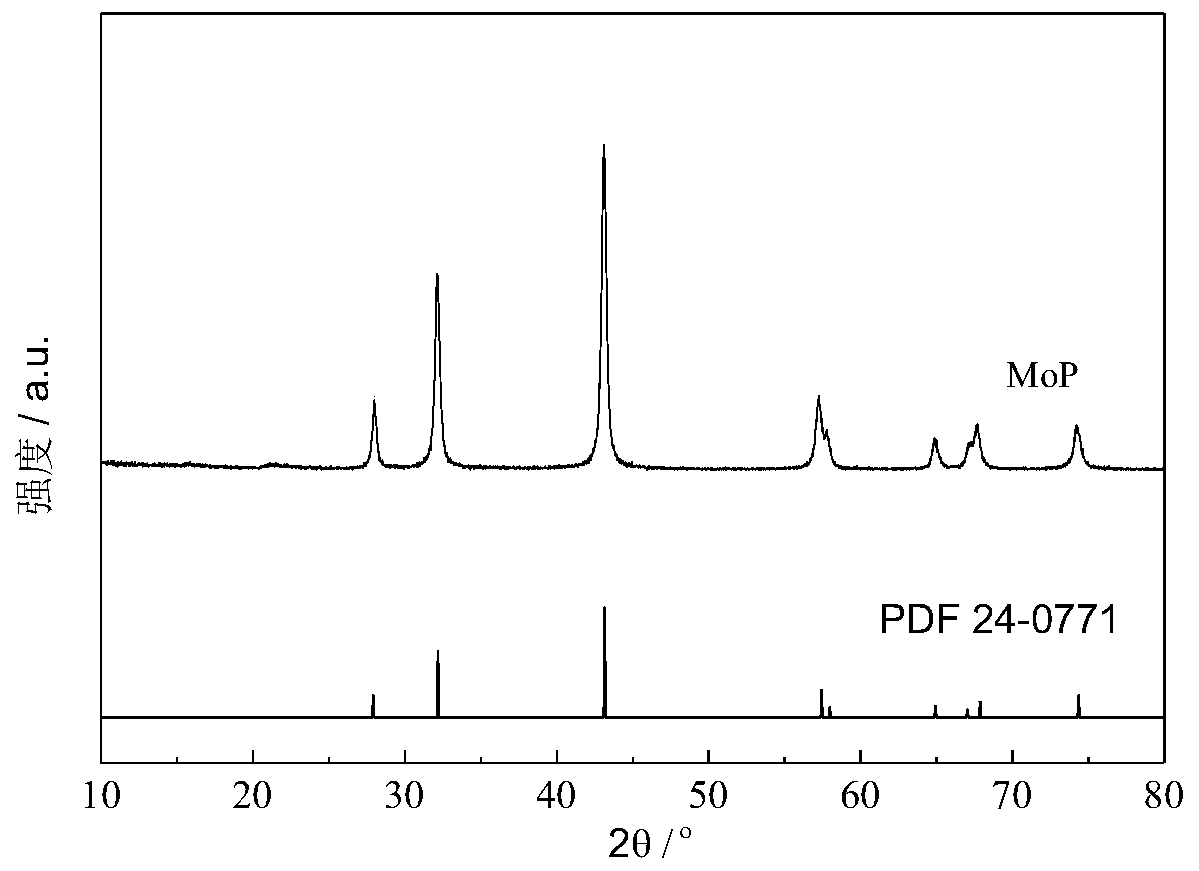

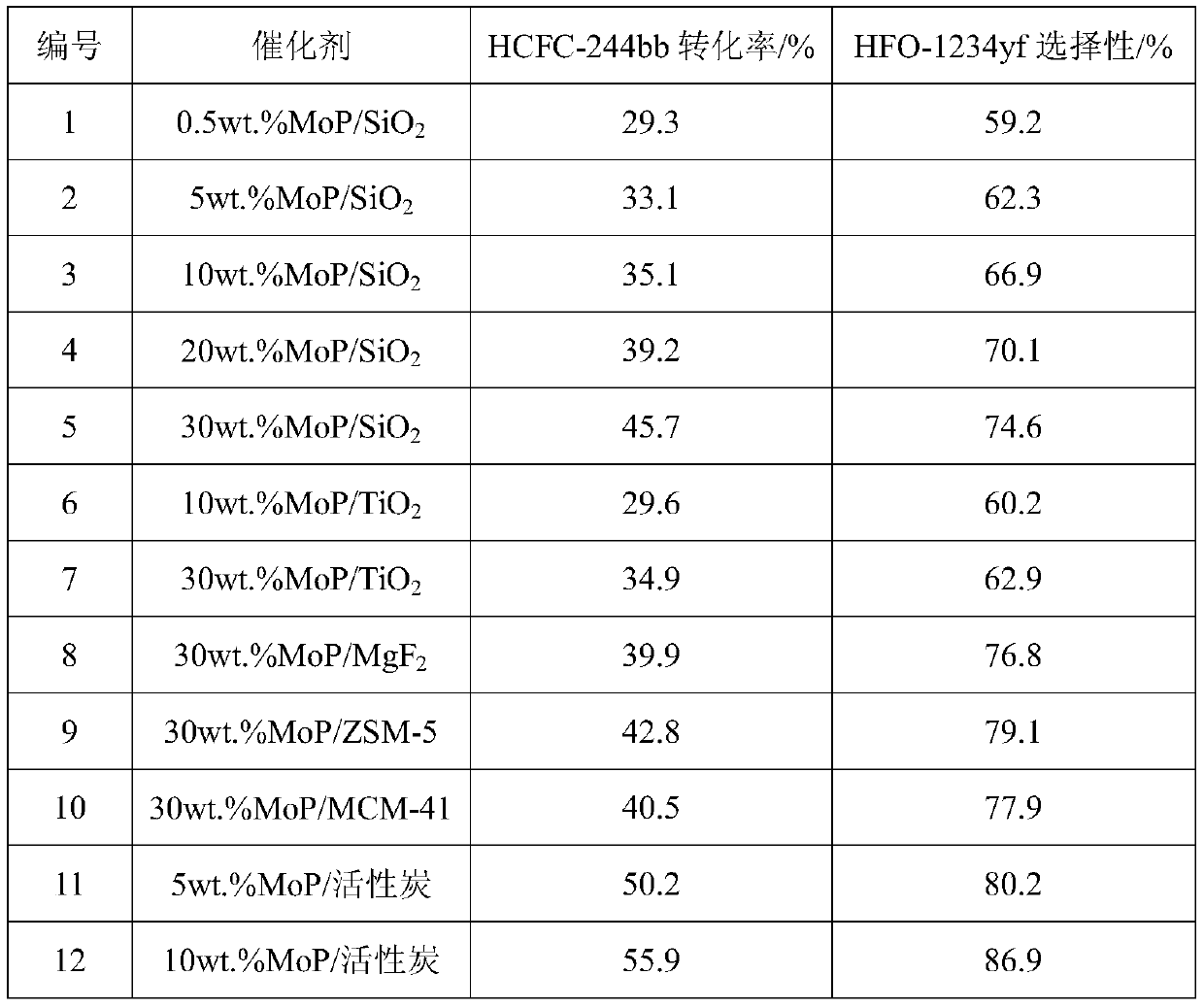

[0022] Embodiment 1: Preparation of MoP / oxide (fluoride or molecular sieve) catalyst

[0023] At room temperature, 3.52 g of ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) and 2.63g diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) was added to 20 mL of deionized aqueous solution, and then the pH of the solution was adjusted to 2-3 with concentrated nitric acid to obtain a clear solution. According to the loading of 0.5%, 5%, 10%, 20%, and 30%, the above solutions are impregnated onto a certain mass of oxides, fluorides, or molecular sieves, and then aged at room temperature for 12 hours, dried at 120 ° C for 12 hours to dry the water, and Calcined at 500°C for 6h to obtain the oxide precursor of supported MoP. The phosphide catalyst was prepared by in-situ temperature-programmed reduction method. The temperature programming step mainly includes two steps: (1) in H 2 Under the atmosphere (flow rate 150mL / min), the temperature was raised from room temperature to ...

Embodiment 2

[0024] Embodiment 2: preparation MoP / activated carbon catalyst

[0025] At room temperature, 3.52 g of ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) and 2.63g diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) was added to 20 mL of deionized aqueous solution, and then the pH of the solution was adjusted to 2-3 with concentrated nitric acid to obtain a clear solution. According to the loads of 5%, 10%, 20%, and 30%, the above solutions were impregnated on a certain mass of activated carbon, and then aged at room temperature for 12 hours, dried at 120°C for 12 hours, and baked at 500°C for 3 hours in a nitrogen atmosphere. Oxide precursors of MoP supported on activated carbon were obtained. The phosphide catalyst was prepared by in-situ temperature-programmed reduction method. The temperature programming step mainly includes two steps: (1) in H 2 Under the atmosphere (flow rate 150mL / min), the temperature was raised from room temperature to 120°C at 5°C / min, and k...

Embodiment 3

[0026] Example 3: Preparation of surface sulfur-modified molybdenum phosphide-supported activated carbon catalyst

[0027] Using the molybdenum phosphide loaded activated carbon catalyst obtained in Example 2, after the sample temperature program reduction was completed, the temperature was lowered to 400 ° C, and the H 2 Switch to containing 10% (volume fraction) H 2 S / H 2 . The sulfidation treatment was continued for 3 hours, and the surface sulfur-modified molybdenum phosphide-supported activated carbon catalyst was obtained, and the active phase was denoted as MoP-S.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com