Preparation method of small-tube-diameter carbon nanotubes

A technology of carbon nanotubes and multi-walled carbon nanotubes, which is applied in the directions of carbon nanotubes, single-walled carbon nanotubes, multi-walled carbon nanotubes, etc. It is easy to fuse and agglomerate to avoid uneven size, huge surface area and activity, and avoid fusion and growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

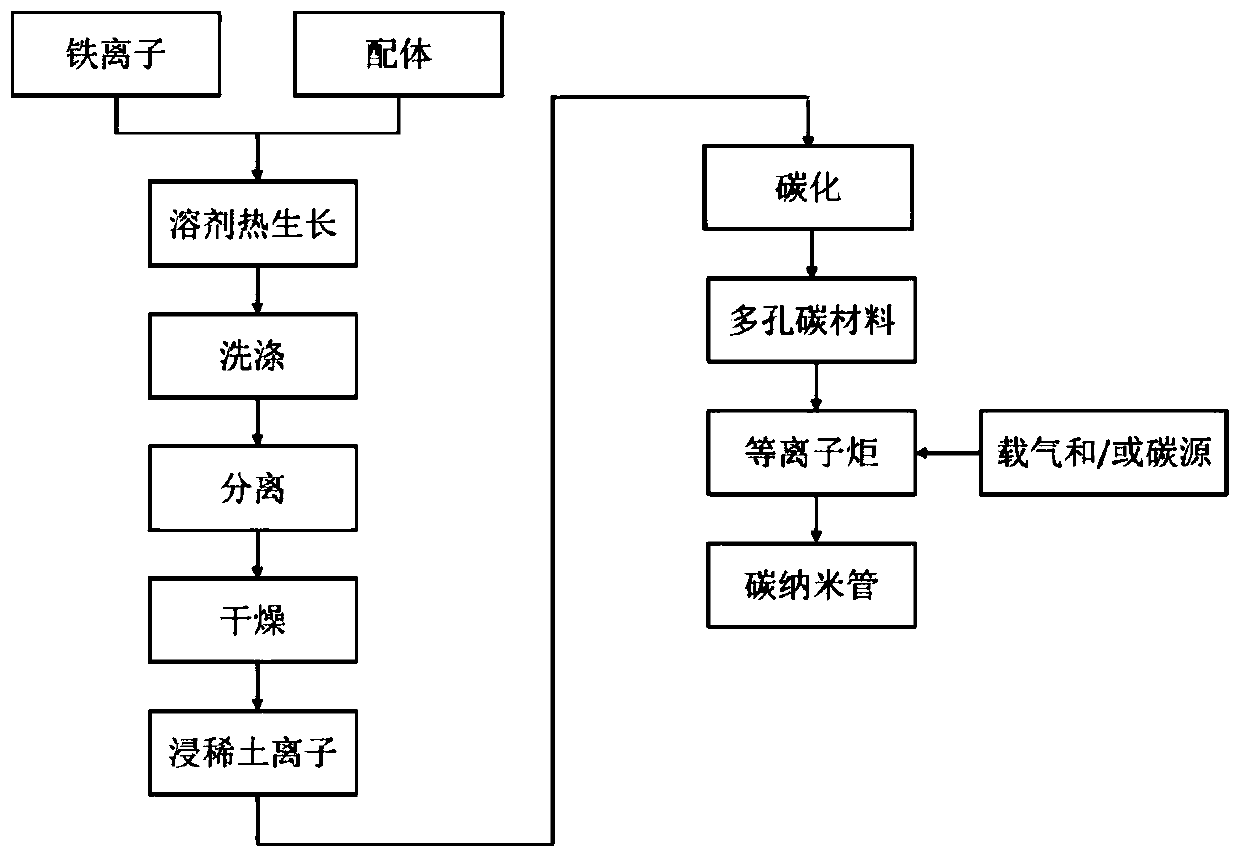

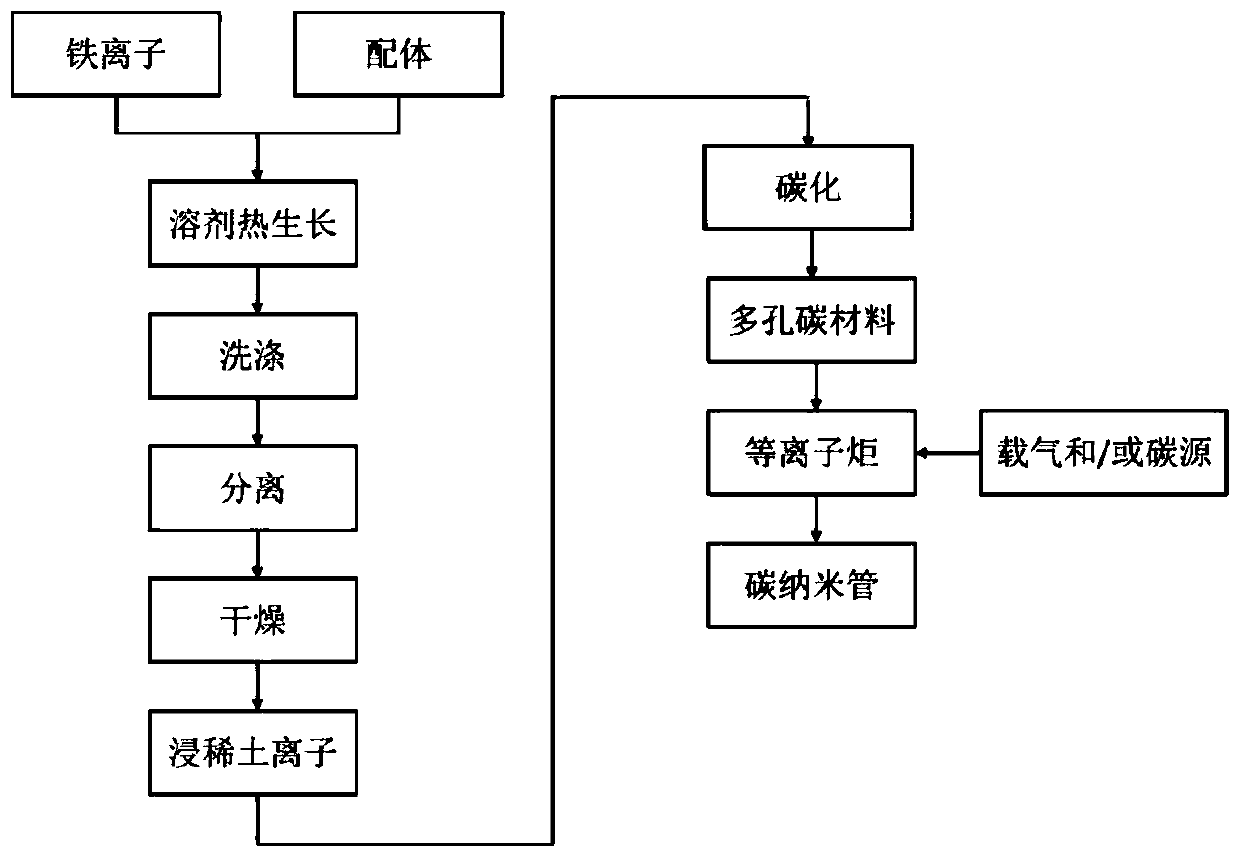

[0030] Such as figure 1 Shown, the preparation method of a kind of thin tube diameter carbon nanotube of the present invention, this method specifically comprises:

[0031] S1. Preparation of iron-containing metal-organic framework compounds;

[0032] S2. After the iron-containing metal organic framework compound prepared in S1 is separated, washed and dried, soaked in a solution containing rare earth ions, and then carbonized in an inert gas to obtain a porous carbon material loaded with iron and rare earth elements;

[0033] S3. The porous carbon material loaded with iron and rare earth elements is treated with a high-temperature plasma torch, and carbon nanotubes with a diameter of ≤5 nanometers are obtained during the downward process.

[0034] According to an embodiment of the present disclosure, the carbon nanotubes are multi-walled carbon nanotubes, double-walled carbon nanotubes or single-walled carbon nanotubes.

[0035] According to an embodiment of the present dis...

Embodiment 1

[0048] 0.01 mol / L ferric chloride and 0.02 mol / L terephthalic acid were solvothermally reacted in NN-dimethylformamide at 150°C for 24 hours, separated and washed, and vacuum-dried at 60°C to obtain iron ion-containing metal organic framework compounds. Then soak in 0.01 mol / L yttrium nitrate solution, separate and dry, and carbonize at 500° C. for 2 hours under a nitrogen atmosphere to obtain a porous carbon material loaded with iron and rare earth. Using 50Kw radio frequency plasma spraying equipment as a high-temperature heat source, firstly evacuate the plasma chamber to 500Torr, then pass in argon: helium = 1:5 mixed arc starting gas from the plasma spray gun, turn on the power of the equipment to obtain a stable plasma torch, Then, the porous carbon material loaded with iron and rare earth is injected through the mixed carrier gas of argon:hydrogen=95:5, the injection flow rate is 0.5 g / s, and enters the ion reaction chamber through the center of the plasma torch, and re...

Embodiment 2

[0050] 1 mol / L ferric sulfate and 4 mol / L phthalic acid were solvothermally reacted in NN-dimethylformamide at 200°C for 72 hours, separated, washed, and vacuum-dried at 60°C to obtain a metal containing iron ions Organic framework compounds. Then soak in a 0.1 mol / L lanthanum nitrate solution, separate and dry, and carbonize at 500° C. for 2 hours under a nitrogen atmosphere to obtain a porous carbon material loaded with iron and rare earth. Using 50Kw radio frequency plasma spraying equipment as a high-temperature heat source, first vacuumize the plasma chamber to 500Torr, then pass in argon: helium = 1:2 mixed arc starting gas from the plasma spray gun, turn on the power of the equipment to obtain a stable plasma torch, Then, the porous carbon material loaded with iron and rare earth is injected through argon:hydrogen=95:5 mixed carrier gas, the injection flow rate is 5 g / s, and enters the ion reaction chamber through the center of the plasma torch, and at the same time, et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com