A preparation method of silicone resin nanoparticle dispersion and silicone resin nanoparticle dispersion

A nanoparticle and silicone resin technology, applied in the field of silicone resin nanoparticle preparation, can solve the problem of not mentioning the preparation of silicone resin nanoparticles, etc., and achieve the effect of stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

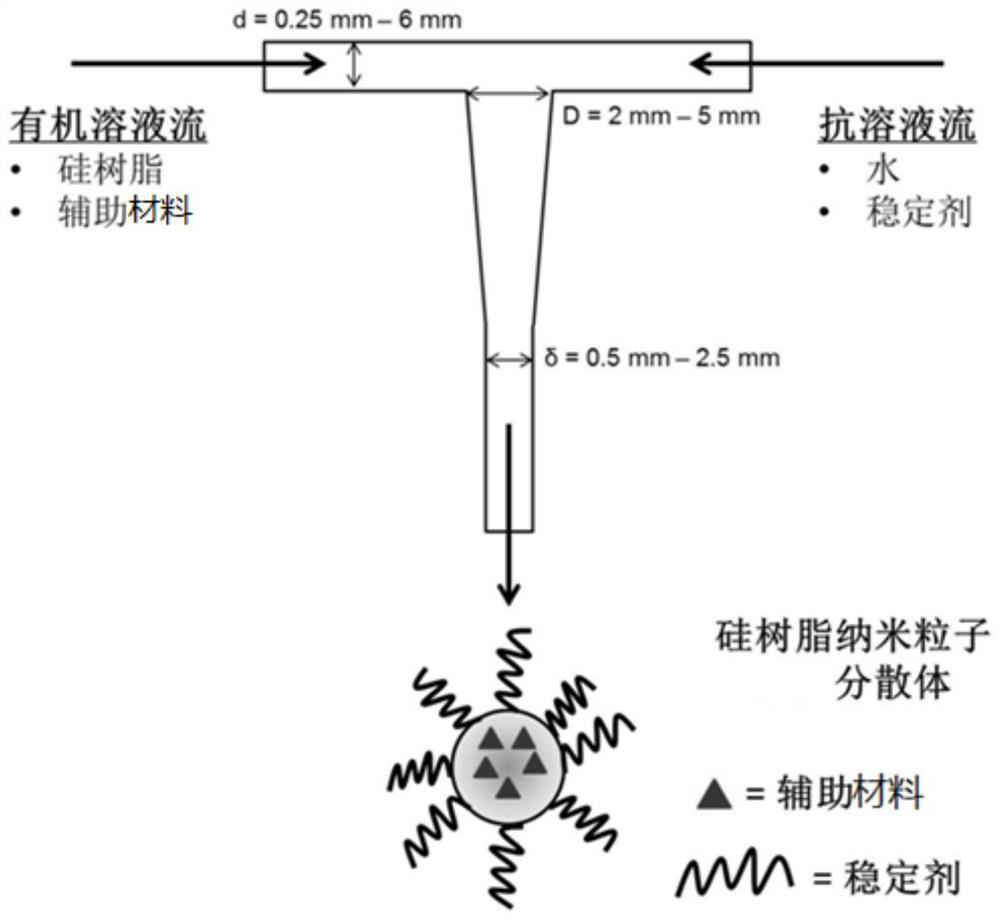

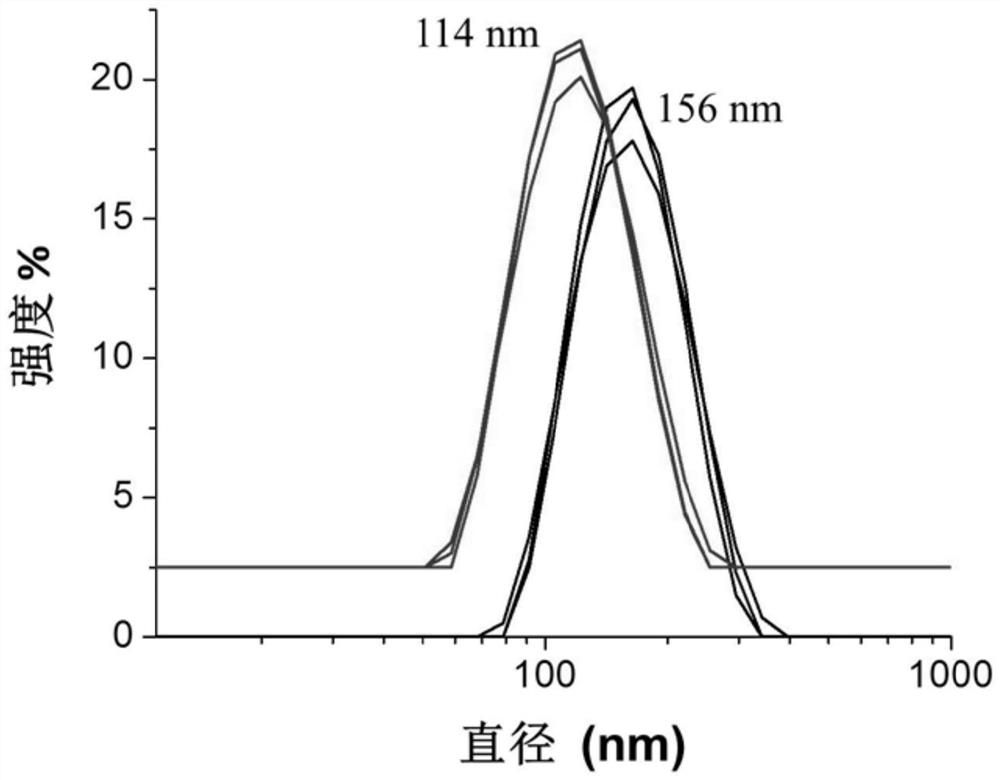

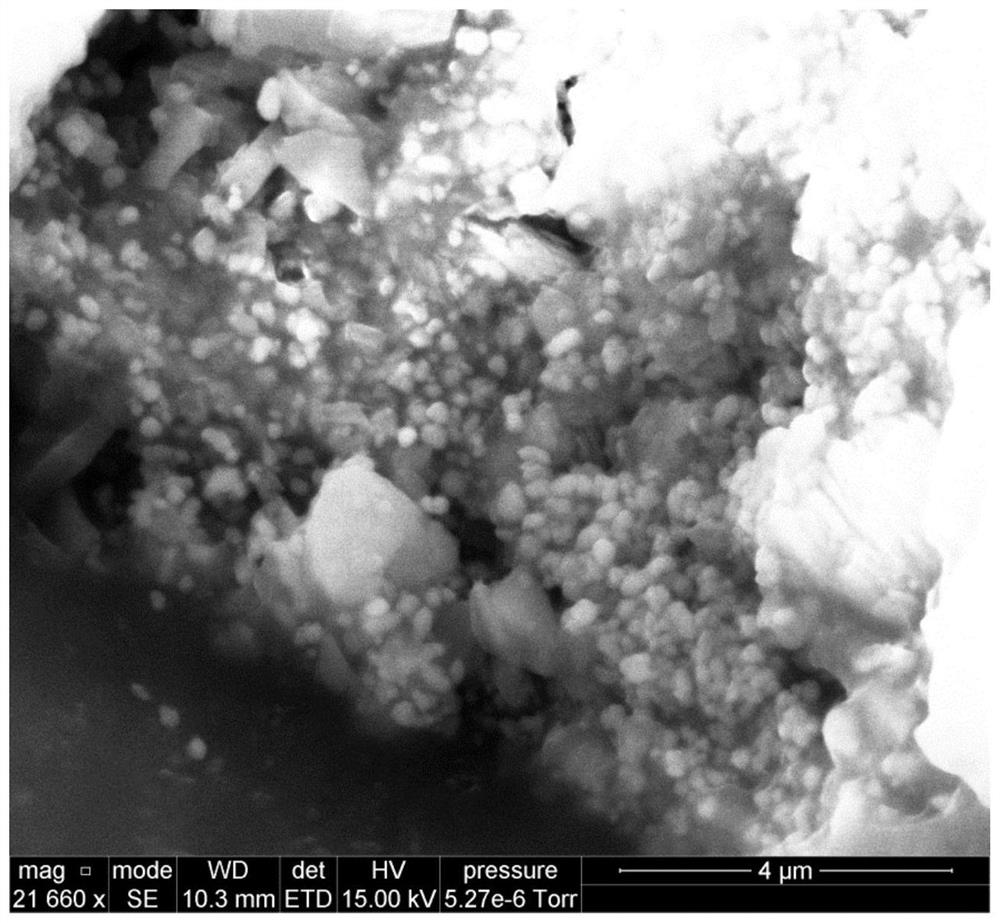

Embodiment 1

[0110] 344 mg of commercial vinyl polydimethylsiloxane was dissolved in 75.7 mL of tetrahydrofuran (THF) to form a tetrahydrofuran solution, and then 34.4 mg of a crosslinking agent was added to the tetrahydrofuran solution and mixed well. Then, put the tetrahydrofuran solution into a 100mL glass syringe, fix it on a syringe pump (Harvard Instruments PHD 2000), and connect it to the solvent inlet tube of the closed impact jet mixer used in the flash method. A second 100 mL glass syringe containing 75.7 mL of distilled water was mounted in the same syringe pump and connected to the antisolvent inflow inlet of the closed impingement jet mixer used for the flash method. The syringe pump pumps the solutions of the two syringes into the closed impact jet mixer at a volume flow rate of 150mL / min, the Reynolds number (Re=ρvd / μ, where v, ρ, μ are the flow rate, density and viscosity coefficient of the fluid respectively , d is the inlet flow diameter) is about 2000, the specific param...

Embodiment 2

[0112] 344 mg of commercial vinyl polydimethylsiloxane was dissolved in 75.7 mL of tetrahydrofuran (THF) to form a tetrahydrofuran solution, and then 34.4 mg of a crosslinking agent was added to the tetrahydrofuran solution and mixed well. Then, the tetrahydrofuran solution was filled into a 140mL polypropylene syringe (Monoject Model, Medtronic), and the syringe was fixed on a syringe pump (Harvard Instruments PHD 2000) and connected to the solvent flow of the closed impact jet mixer used in the flash method. inlet pipe. A second 140-mL polypropylene syringe, containing 75.7 mL of distilled water, was mounted in the same syringe pump and connected to the solution-resistant inlet of the closed impingement jet mixer used for the flash method. The syringe pump pumps the solutions of the two syringes into the closed impact jet mixer at a volume flow rate of 220mL / min, the Reynolds number (Re=ρvd / μ, where v, ρ, μ are the flow rate, density and viscosity of the fluid respectively ...

Embodiment 3

[0114] 1376 mg of commercial vinyl polydimethylsiloxane was dissolved in 75.7 mL of tetrahydrofuran (THF) to form a tetrahydrofuran solution, and then 137.6 mg of a crosslinking agent was added to the tetrahydrofuran solution and mixed well. Then, put the tetrahydrofuran solution into a 100mL glass syringe, fix it on a syringe pump (Harvard Instruments PHD 2000), and connect it to the solvent inlet tube of the closed impact jet mixer used in the flash method. A second 100 mL glass syringe containing 75.7 mL of distilled water was mounted in the same syringe pump and connected to the antisolvent inflow inlet of the closed impingement jet mixer used for the flash method. The syringe pump pumps the solutions of the two syringes into the closed impact jet mixer at a volume flow rate of 150mL / min, the Reynolds number (Re=ρvd / μ, where v, ρ, μ are the flow rate, density and viscosity coefficient of the fluid respectively , d is the inlet flow diameter) is about 2000, the specific par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com