Low-fluorine hydrophobic latex film and preparation method thereof

A technology of water emulsion and polyacrylate emulsion, which is applied in the field of hydrophobic materials, can solve the problems that the cost and performance effect of fluorine-containing polyacrylate coatings cannot be taken into account at the same time, and the preparation process is complicated, and achieves excellent hydrophobicity, increased surface roughness, The effect of improving hydrophobicity and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

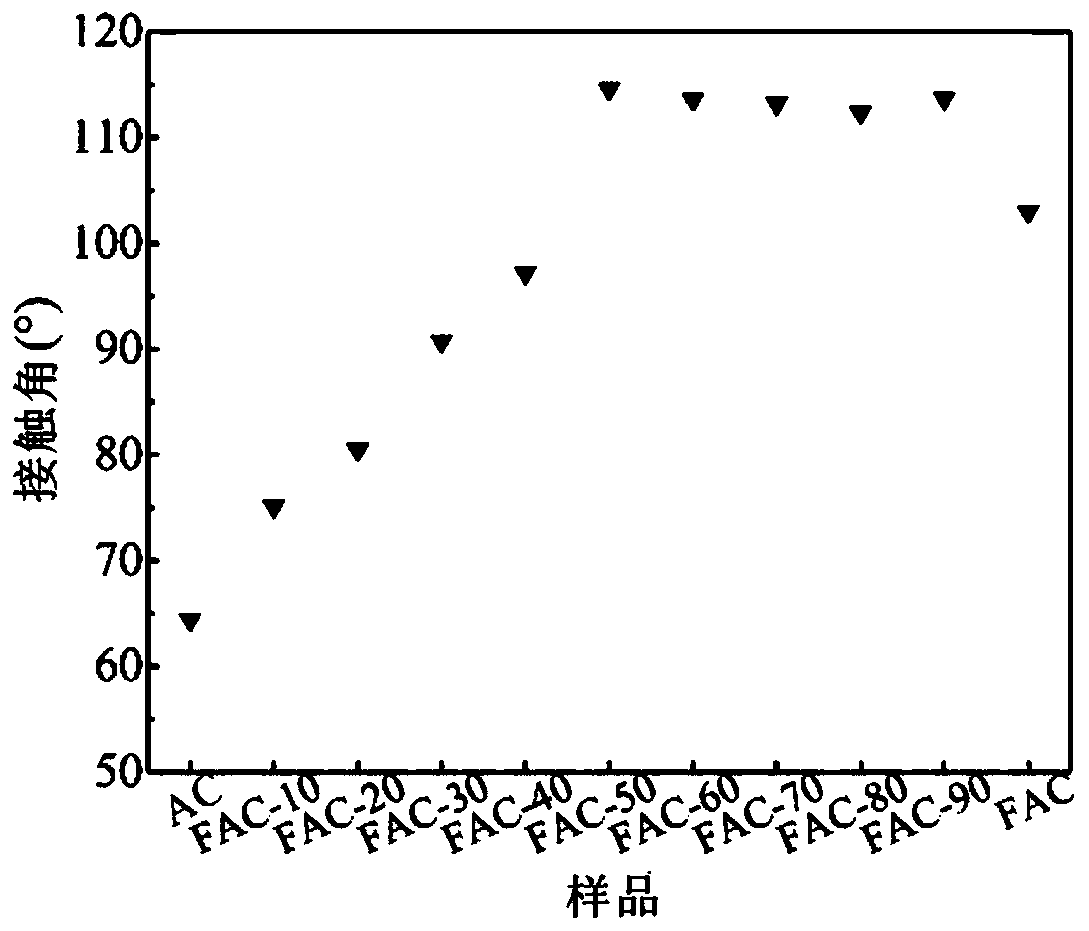

[0046] The low-fluorine hydrophobic latex film of the present embodiment is cured after blending the following raw materials: 10wt% fluorine-containing polyacrylate emulsion and 90wt% non-fluorine-containing polyacrylate emulsion; the solid content in the mixed emulsion after blending is 45wt%, the fluorine content is 1wt%.

[0047] Among them, the fluorine-containing polyacrylate emulsion is prepared by the following raw materials: fluorine-containing acrylate monomers accounting for 15 wt% of the total monomer mass, 85 wt% acrylate monomers accounting for the total monomer mass, accounting for 1.5 wt% of the total monomer mass Surfactant, the initiator accounting for 0.15wt% of the total mass of the monomer, the co-stabilizer accounting for 1.5wt% of the total mass of the monomer, and 3 times the water of the total mass of the monomer; wherein, the total mass of the monomer is The sum of the mass of fluoroacrylate monomer and acrylate monomer.

[0048] The fluorine-containi...

Embodiment 2

[0058] The low-fluorine hydrophobic latex film of the present embodiment is cured after blending the following raw materials: 90wt% fluorine-containing polyacrylate emulsion and 10wt% non-fluorine-containing polyacrylate emulsion; the solid content in the mixed emulsion after blending is 23wt%, and the fluorine content is 9wt%.

[0059] Among them, the fluorine-containing polyacrylate emulsion is prepared by the following raw materials: fluorine-containing acrylate monomer accounting for 25wt% of the total monomer mass, 75wt% acrylate monomer accounting for the total monomer mass, accounting for 3.5wt% of the total monomer mass Surfactant, the initiator accounting for 0.4wt% of the total mass of the monomer, the co-stabilizer accounting for 3.5wt% of the total mass of the monomer, and 3 times the water of the total mass of the monomer; wherein, the total mass of the monomer is The sum of the mass of fluoroacrylate monomer and acrylate monomer.

[0060] The fluorine-containing...

Embodiment 3

[0070] The low-fluorine hydrophobic latex film of the present embodiment is cured after blending the following raw materials: 20wt% fluorine-containing polyacrylate emulsion and 80wt% non-fluorine-containing polyacrylate emulsion; the solid content in the mixed emulsion after blending is 42wt%, the fluorine content is 2wt%.

[0071] Among them, the fluorine-containing polyacrylate emulsion is prepared by the following raw materials: fluorine-containing acrylate monomers accounting for 20 wt% of the total monomer mass, accounting for 80 wt% of the total monomer mass acrylate monomers, accounting for 2.5 wt% of the total monomer mass Surfactant, the initiator accounting for 0.3wt% of the total mass of the monomer, the co-stabilizer accounting for 2.5wt% of the total mass of the monomer, and 3.5 times the water of the total mass of the monomer; wherein, the total mass of the monomer is The sum of the mass of fluoroacrylate monomer and acrylate monomer.

[0072] The fluorine-cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com