Bucket tooth made of wear-resistant composite material, and preparation method thereof

A composite material and tooth head technology, which is applied in the field of wear-resistant composite material bucket teeth and its preparation, can solve the problems of poor wear resistance, high working stress, and short service life, so as to improve wear resistance, increase service life, prevent Fracture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

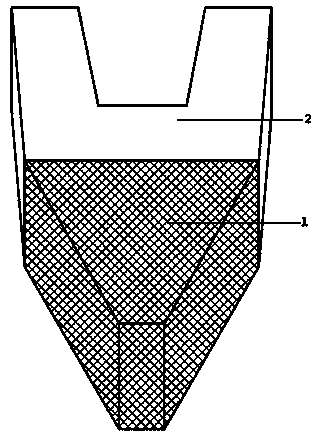

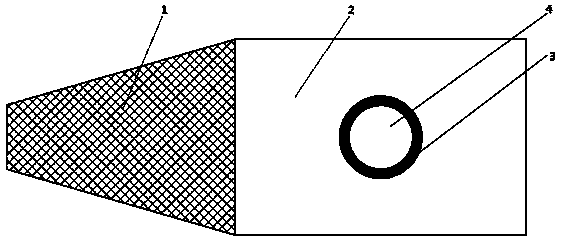

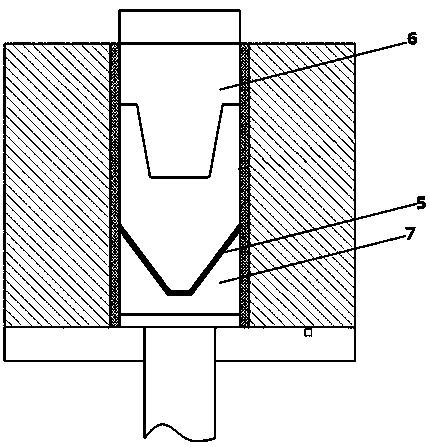

[0026] A wear-resistant composite bucket tooth, such as figure 1 , 2 As shown, it includes a composite tooth head 1, a metal matrix tooth tail 2, and a rubber ring 3. The composite material tooth head 1 is connected to the metal matrix tooth tail 2. There is a pin hole 4 on the metal matrix tooth tail 2, and the hole is covered with Rubber ring 3.

[0027] The specific steps of the preparation method of the wear-resistant composite material bucket tooth in this embodiment are as follows: uniformly mix 100-mesh iron powder and 80-mesh alumina ceramic particles, the mass percentage of reduced iron powder in the iron powder is ≥99%, and then add Anhydrous ethanol with 10% of the mass of ceramic particles was ball milled for 2 hours to obtain a mixed powder, and then a binder water glass with a mass of 6% of the mass of ceramic particles was added. After stirring evenly, it was filled into a tooth head mold. It is a 2450MHz microwave oven, and after being calcined for 2 hours, i...

Embodiment 2

[0030] A wear-resistant composite material bucket tooth, comprising a composite tooth head 1, a metal matrix tooth tail 2, and a rubber ring 3, the composite material tooth head 1 is connected to the metal matrix tooth tail 2, and the metal matrix tooth tail 2 is provided with a pin hole 4. A rubber ring 3 is sleeved in the hole.

[0031] The specific steps of the preparation method of the wear-resistant composite material bucket tooth in this embodiment are as follows: uniformly mix 200-mesh iron powder with 120-mesh zirconium corundum ceramic particles, the mass percentage of reduced iron powder in the iron powder is ≥99%, and then add ceramic particles 18% absolute ethanol by mass, ball milled for 4 hours to obtain a mixed powder, the mass percentage of iron powder in the mixed powder is 30%, then add a binder silica sol with a mass of 8% ceramic particles, stir evenly, and fill it into the tooth head type In the mould, a microwave oven with a microwave power of 1600W and a...

Embodiment 3

[0034] A wear-resistant composite material bucket tooth, comprising a composite tooth head 1, a metal matrix tooth tail 2, and a rubber ring 3, the composite material tooth head 1 is connected to the metal matrix tooth tail 2, and the metal matrix tooth tail 2 is provided with a pin hole 4. A rubber ring 3 is sleeved in the hole.

[0035] The specific steps of the preparation method of the wear-resistant composite material bucket tooth in this embodiment are as follows: uniformly mix 150-mesh iron powder and 100-mesh silicon carbide ceramic particles, the mass percentage of reduced iron powder in the iron powder is ≥99%, and then add ceramic particles 14% by mass of absolute ethanol, ball milled for 3 hours to obtain a mixed powder, the mass percentage of iron powder in the mixed powder is 60%, and then add the binder polyvinyl alcohol of 7% by mass of ceramic particles, stir evenly, and fill it into the tooth head In the mold, a microwave oven with a microwave power of 2400W ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com