High-thermal conductivity insulating film for lithium ion and preparation method thereof

A high thermal conductivity, insulating film technology, used in electrical components, electrochemical generators, circuits, etc., can solve problems such as lithium-ion battery safety problems, thermal runaway, short circuit or overcharge that cannot be fundamentally solved , to achieve the effects of easy operation, high thermal conductivity and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Use a pulverizer to crush the polypropylene material with a thermal conductivity of 0.23W / mk into particles with a diameter of <1mm, wherein the polypropylene material accounts for 80% by weight;

[0029] Step 2: Use a hot-melt machine to heat it to 200±5°C to melt it, add Al2O3 with a particle size of 100-500 microns in proportion, and the mass of Al2O3 accounts for 20% of the total mass, and stir for 5 hours to make the two materials fully mix evenly;

[0030] Step 3: Put it into the feeding system again, pass through the plasticizing machine, prepare a film with a thickness of 0.15mm, and then cool it

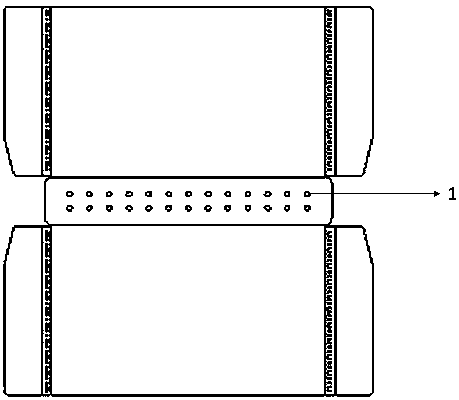

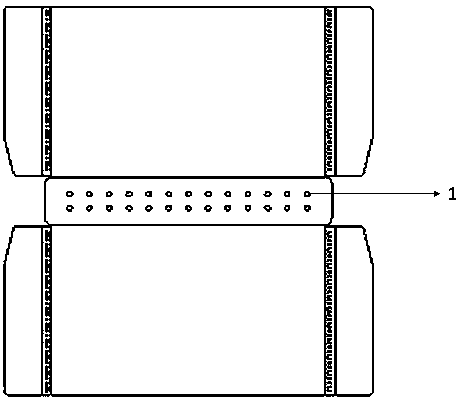

[0031] Step 4: After the film is cooled, use a cutting machine to cut into such figure 1 In the shape shown, the insulating film with high thermal conductivity was prepared.

[0032] Take five pieces of the above-mentioned insulating film and soak them in the electrolyte solution, place them in a constant temperature box at 60°C for 7 days, and observe the c...

Embodiment 2

[0036] Step 1: Use a pulverizer to pulverize polypropylene with a thermal conductivity of 0.23W / mk into particles with a diameter of <1mm, wherein the proportion of polypropylene material is 80% by weight;

[0037] Step 2: Use a hot-melt machine to heat it to 200±5°C to melt it, add SiO2 with a particle size of 100-500 microns in proportion, and the mass of the SiO2 accounts for 20% of the total mass, and stir for 5 hours to make the two materials Mix well and evenly;

[0038] Step 3: Put it into the feeding system again, pass through the plasticizing machine, prepare a film with a thickness of 0.15mm, and then cool it

[0039] Step 4: After the film is cooled, use a cutting machine to cut into such figure 1 In the shape shown, the insulating film with high thermal conductivity was prepared.

[0040] Take five pieces of the above-mentioned insulating film and soak them in the electrolyte solution, place them in a constant temperature box at 60°C for 7 days, and observe the c...

Embodiment 3

[0044] Step 1: Use a pulverizer to pulverize polypropylene with a thermal conductivity of 0.23W / mk into particles with a diameter of <1mm, wherein the proportion of polypropylene material is 80% by weight;

[0045] Step 2: Use a hot-melt machine to heat it to 200±5°C to melt it, add BN with a particle size of 100-500 microns in proportion, and the mass of the BN accounts for 20% of the total mass, and stir for 5 hours to make the two materials fully mix evenly;

[0046] Step 3: Put it into the feeding system again, pass through the plasticizing machine, prepare a film with a thickness of 0.15mm, and then cool it

[0047] Step 4: After the film is cooled, use a cutting machine to cut into such figure 1 shape shown, that is prepared into the high thermal conductivity insulating film

[0048] Take five pieces of the above-mentioned insulating film and soak them in the electrolyte solution, place them in a constant temperature box at 60°C for 7 days, and observe the corrosion re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com