Preparation method of tuna protein peptide

The technology of tuna and protein peptide is applied in the field of preparation of tuna protein peptide, which can solve the problems of lack of a good preparation method, increased work difficulty, high production cost, etc., and achieves enhancement of human immunity, good skin-beautifying and moisturizing effects, and improved utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

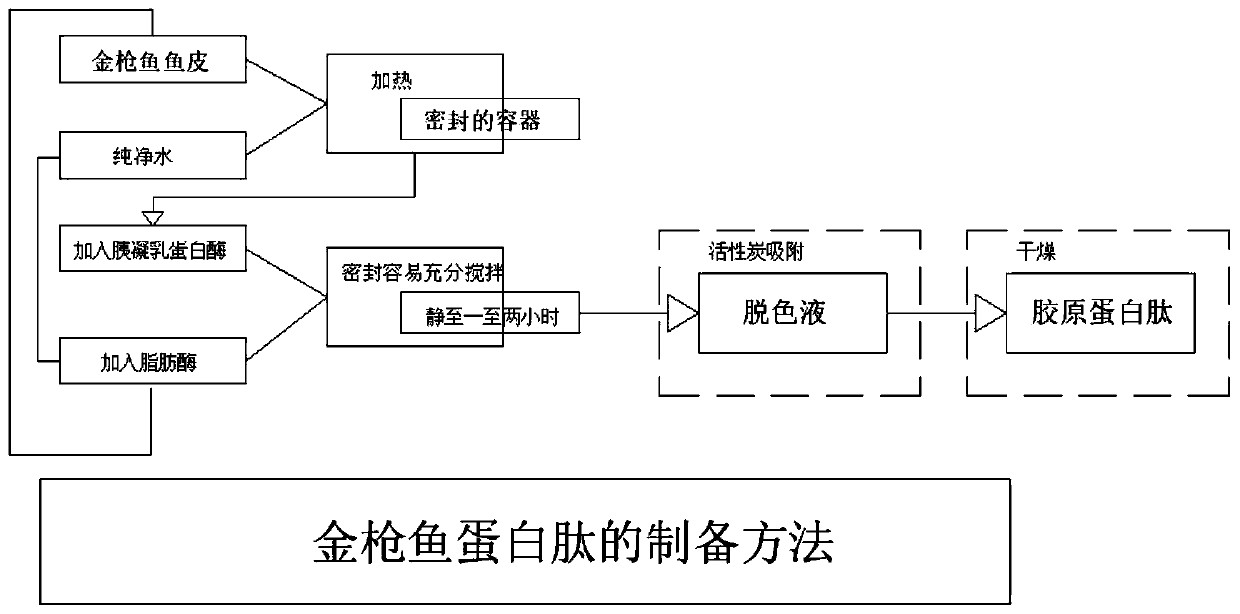

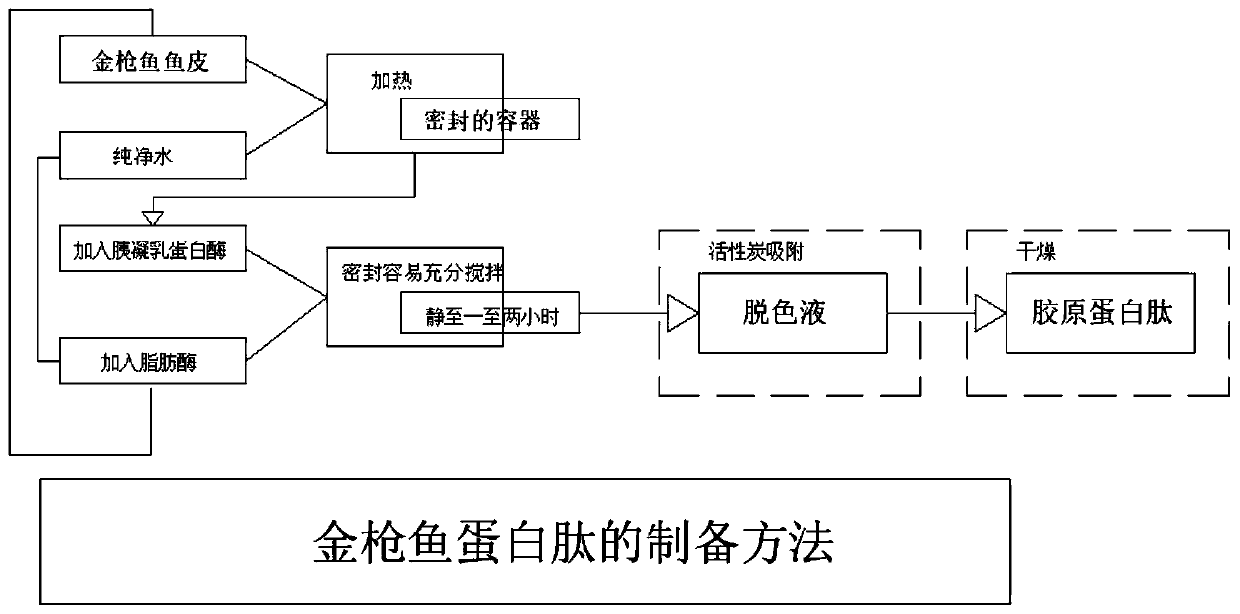

[0021] see figure 1 , the present invention provides a technical solution: a preparation method of tuna protein peptide, comprising the following steps, the

[0022] Step 1: First choose fresh tuna skin as the raw material, then mix the fish skin with water at a ratio of 1:30, and then heat it to the boiling point in a sealed container so that the water temperature is always kept at 100 degrees Celsius. This process lasts for two After three hours, a mixed solution was obtained;

[0023] Step 2: Cool down the obtained mixed solution to 40-65 degrees Celsius, then add enzymes to the mixed solution, let it stand for one to two hours and then fully stir;

[0024] Step 3: Then add chymotrypsin and lipase to the mixed solution stirred in step 2, and stir for two to four hours for enzymolysis to obtain an enzymolysis solution;

[0025] Step 4: decolorize the enzymatic solution with activated carbon, filter to obtain a decolorized solution, and obtain collagen peptides after purifi...

Embodiment 2

[0032] A preparation method of tuna protein peptide, comprising the following steps, the

[0033] Step 1: First select fresh tuna skin as the raw material, then mix the fish skin with water at a ratio of 1:25, and then heat it to the boiling point in a sealed container so that the water temperature is always kept at 90-100 degrees Celsius. This process After maintaining for two hours, a mixed solution was obtained;

[0034] Step 2: Cool down the obtained mixed solution to 50 degrees Celsius, then add enzymes to the mixed solution, let it stand for one to two hours, and then fully stir;

[0035] Step 3: Then add chymotrypsin and lipase to the mixed solution stirred in step 2, and stir for three hours for enzymolysis to obtain an enzymolysis solution;

[0036] Step 4: decolorize the enzymatic solution with activated carbon, filter to obtain a decolorized solution, and obtain collagen peptides after purification and drying.

Embodiment 3

[0038] In the step 2, the stirring speed is 60 rpm, and the stirring time is 13 minutes; in the step 3, the stirring speed after adding chymotrypsin and lipase is 90 rpm, and the stirring time is 40 minutes .

[0039]The working principle and application process of the present invention: first select fresh tuna skin as raw material, then mix the fish skin and water according to the ratio of 1:30, then put it in a sealed container and heat it to the boiling point, so that the water temperature is always kept at 100 Celsius, the process is maintained for two to three hours to obtain a mixed solution; the obtained mixed solution is cooled to 40-65 degrees Celsius, then the enzyme is added to the mixed solution, and it is fully stirred after one to two hours; Add chymotrypsin and lipase to the mixed solution, stir and enzymolyze for two to four hours to obtain an enzymolyzed solution; decolorize and decolorize the enzymolyzed solution with activated carbon, filter to obtain a deco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com