Positive plate, preparation method thereof and battery

A positive electrode sheet and positive active material technology, which is applied in the field of positive electrode sheet and its preparation, can solve the problems of gas production and safety problems of high-nickel positive electrode materials, affect the performance of lithium-ion batteries, and destroy the crystal structure, so as to improve the discharge rate performance, is conducive to full wetting, and reduces the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

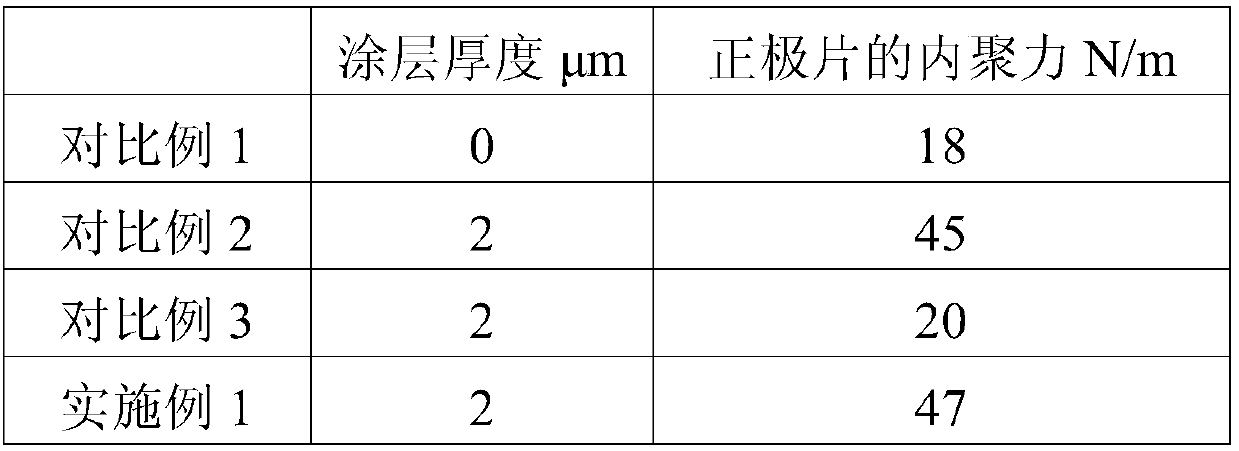

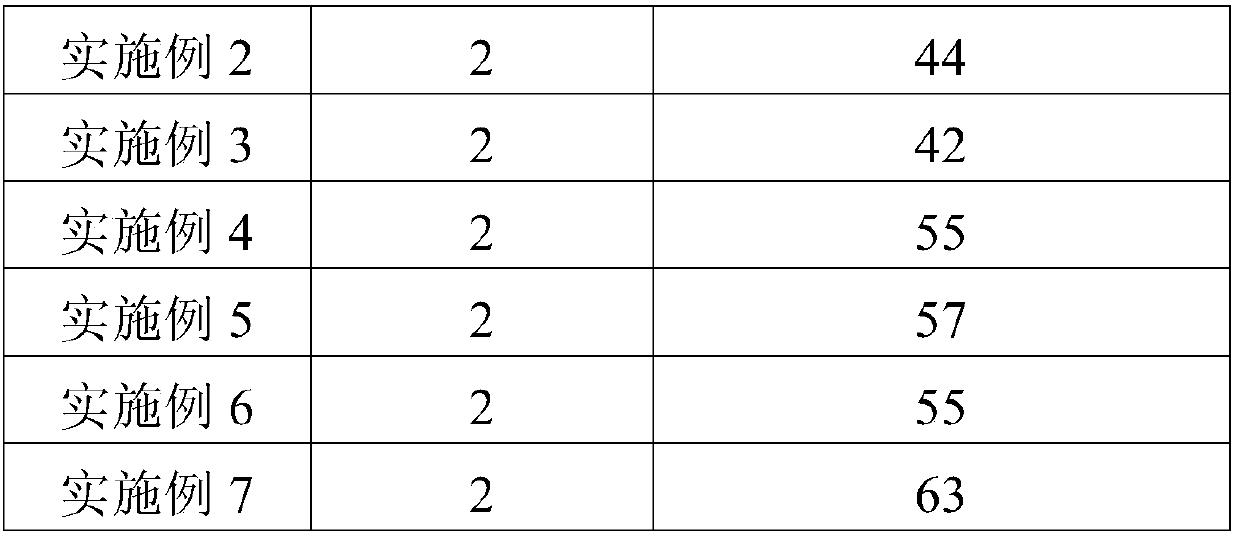

[0012] First, the preparation method of the positive electrode sheet according to the first aspect of the present invention is described, which includes the step: S1, coating the slurry containing the positive electrode active material, the conductive agent, and the binder on the current collector, and after drying, the initial positive electrode sheet is obtained ; S2, mix polymerizable substances, additives and low-boiling point solvents uniformly to prepare a coating solution, then apply the coating solution to the surface of the initial positive electrode sheet, dry and remove the low-boiling point solvent to form a coating; S3, the initial positive electrode The sheet is left to stand in the air for a period of time, and then further heated and baked to remove the additives in the coating to form a porous structure in the coating to complete the preparation of the positive electrode sheet. Wherein, the polymerizable substance is a substance that can spontaneously polymeriz...

Embodiment 1

[0056] Prepare lithium-ion battery according to the same method as Comparative Example 1, the difference is:

[0057] (1) Preparation of positive electrode sheet:

[0058] The cathode active material LiNi 0.8 mn 0.1 co 0.1 o 2 , the conductive agent acetylene black, and the binder polyvinylidene fluoride are mixed in the N-methylpyrrolidone solvent system according to the mass ratio of 94:3:3, and then coated on the current collector Al foil, dried and cooled. Press to obtain the initial positive electrode sheet.

[0059] Sodium silicate and glycerol were dissolved in deionized water to prepare a coating solution with a mass fraction of 30%, wherein the mass ratio of sodium silicate to glycerol was 70%:30%. Coating the coating solution on the surface of the initial positive electrode sheet, after the coating is completed, drying and removing water at 60°C to 80°C, and then leaving the initial positive electrode sheet in a high-humidity environment (air humidity greater th...

Embodiment 2

[0061] Prepare lithium-ion battery according to the same method as Comparative Example 1, the difference is:

[0062] (1) Preparation of positive electrode sheet:

[0063] The cathode active material LiNi 0.8 mn 0.1 co 0.1 o 2 , the conductive agent acetylene black, and the binder polyvinylidene fluoride are mixed in the N-methylpyrrolidone solvent system according to the mass ratio of 94:3:3, and then coated on the current collector Al foil, dried and cooled. Press to obtain the initial positive electrode sheet.

[0064] Potassium phosphate and glycerol were dissolved in deionized water to prepare a coating solution with a mass fraction of 30%, wherein the mass ratio of potassium phosphate to glycerol was 70%:30%. Coating the coating solution on the surface of the initial positive electrode sheet, after the coating is completed, drying and removing water at 60°C to 80°C, and then leaving the initial positive electrode sheet in a high-humidity environment (air humidity grea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com