Composite agarose microsphere and preparation method and application thereof

A technology of agarose microspheres and agarose, which is applied in the field of materials, can solve the problems of short drug action time, large toxic and side effects in the human body, poor biological stability, etc., and achieve the effect of easy promotion and application, cheap and large coating volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

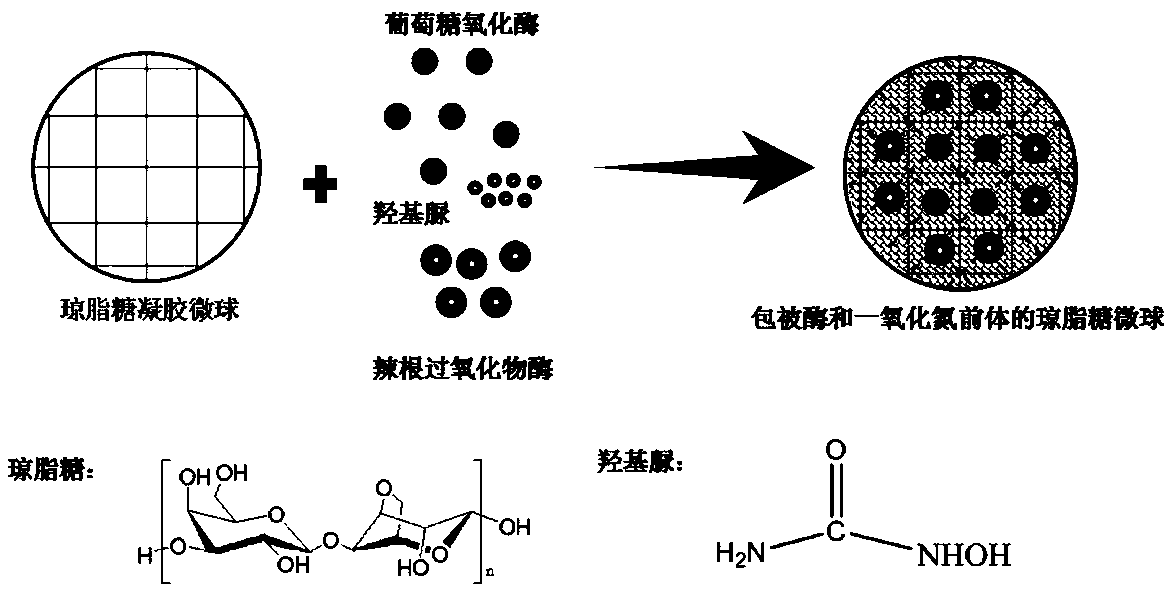

[0035] A composite agarose microsphere of the present invention, comprising hydroxyurea, β-D-glucose oxidoreductase and horseradish peroxidase, coated with hydroxyurea, β-D-glucose oxidoreductase and horseradish peroxidase Form complex agarose microspheres in agarose. figure 1 It is a schematic diagram of agarose microspheres coated with cascade enzymes, and its preparation method comprises the following steps:

[0036] (1) Prepare the organic phase: Mix 18 mL of toluene, 7 mL of chloroform and 0.3 mL of sorbitan fatty acid ester to form the organic phase. Add the above organic phase into a 100 mL flask and preheat to 55 °C at 1000 rpm.

[0037] (2) Preparation of water phase: Take 5 ml of water and add 84 mg of agarose, heat to dissolve, and obtain an agarose solution. When the temperature of the agarose solution dropped to 55°C, add 0.1 mL of β-D-glucose oxidoreductase solution with a pH of 7.0 and a concentration of 1 mg / mL and 0.5 mL of a peppery solution with a concentr...

Embodiment 2

[0040] A composite agarose microsphere of the present invention, comprising hydroxyurea, β-D-glucose oxidoreductase and ferric iron tetroxide nanoparticles, coated with hydroxyurea, β-D-glucose oxidoreductase and ferric iron tetroxide nanoparticles Form complex agarose microspheres in agarose. Its preparation method comprises the following steps:

[0041] (1) Prepare the organic phase: Mix 18 mL of toluene, 7 mL of chloroform and 0.3 mL of sorbitan fatty acid ester to form the organic phase. Add the above organic phase into a 100 mL flask and preheat to 55 °C at 1000 rpm.

[0042](2) Preparation of the water phase: Take 5 ml of water and add 84 mg of agarose, heat to dissolve to obtain an agarose solution. When the temperature of the agarose solution dropped to 55°C, add 0.1 mL of β-D-glucose oxidoreductase solution with a pH of 7.0 and a concentration of 1 mg / mL and 0.5 mL of a solution of β-D-glucose oxidoreductase with a concentration of 1 mg / mL and a pH of 7.0 Ferric ox...

experiment example 1

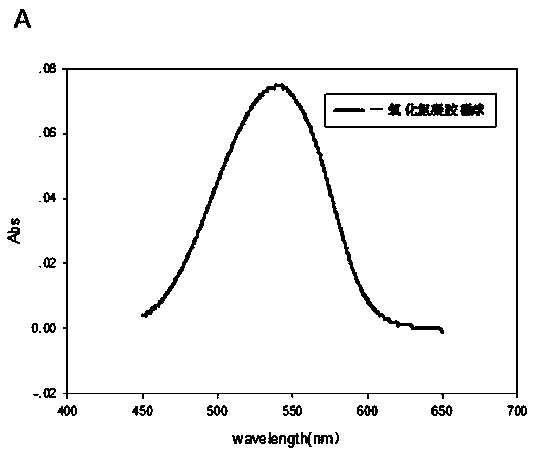

[0045] Take 200 μL of the agarose composite microspheres of Example 1 (the total gel mass is 0.3 mg, and the number of microspheres is 2.0×10 5 ) into a glucose solution with a concentration of 10 mmol / L, reacted for 30 min, added Griess reagent (nitric oxide detection reagent), put it into an ultraviolet spectrophotometer to detect the characteristic absorption peak, and unloaded nitric oxide precursor Enzyme-coated agarose microspheres were used as blank control.

[0046] figure 2 It is the ultraviolet spectrogram of the agarose composite microsphere. It can be seen from the figure that the agarose composite microsphere produces nitric oxide, which makes the Griess reagent have a characteristic absorption peak at 540nm.

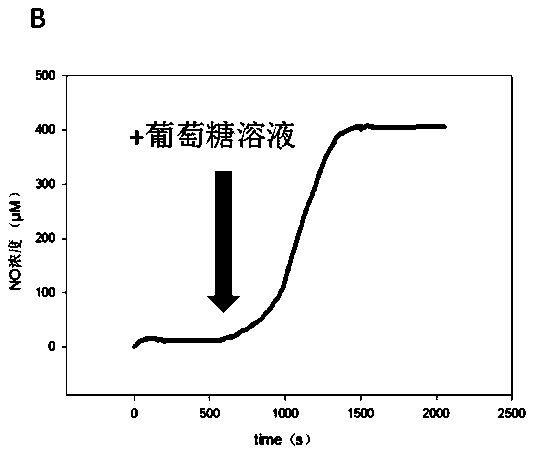

[0047] image 3 is the curve of nitric oxide production versus time. It can be seen from the figure that as time goes by, the content of nitric oxide increases in an S-curve.

[0048] from figure 2 with image 3 It can be known that the agarose comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com