Preparation method and application of attapulgite composite material with plasmon resonance effect

The technology of plasmon resonance and attapulgite is applied in the field of preparation of composite photocatalytic materials, which can solve the problems of high price and cannot be put into large-scale application, and achieve the effects of improving utilization rate, good reusability and reducing compound rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

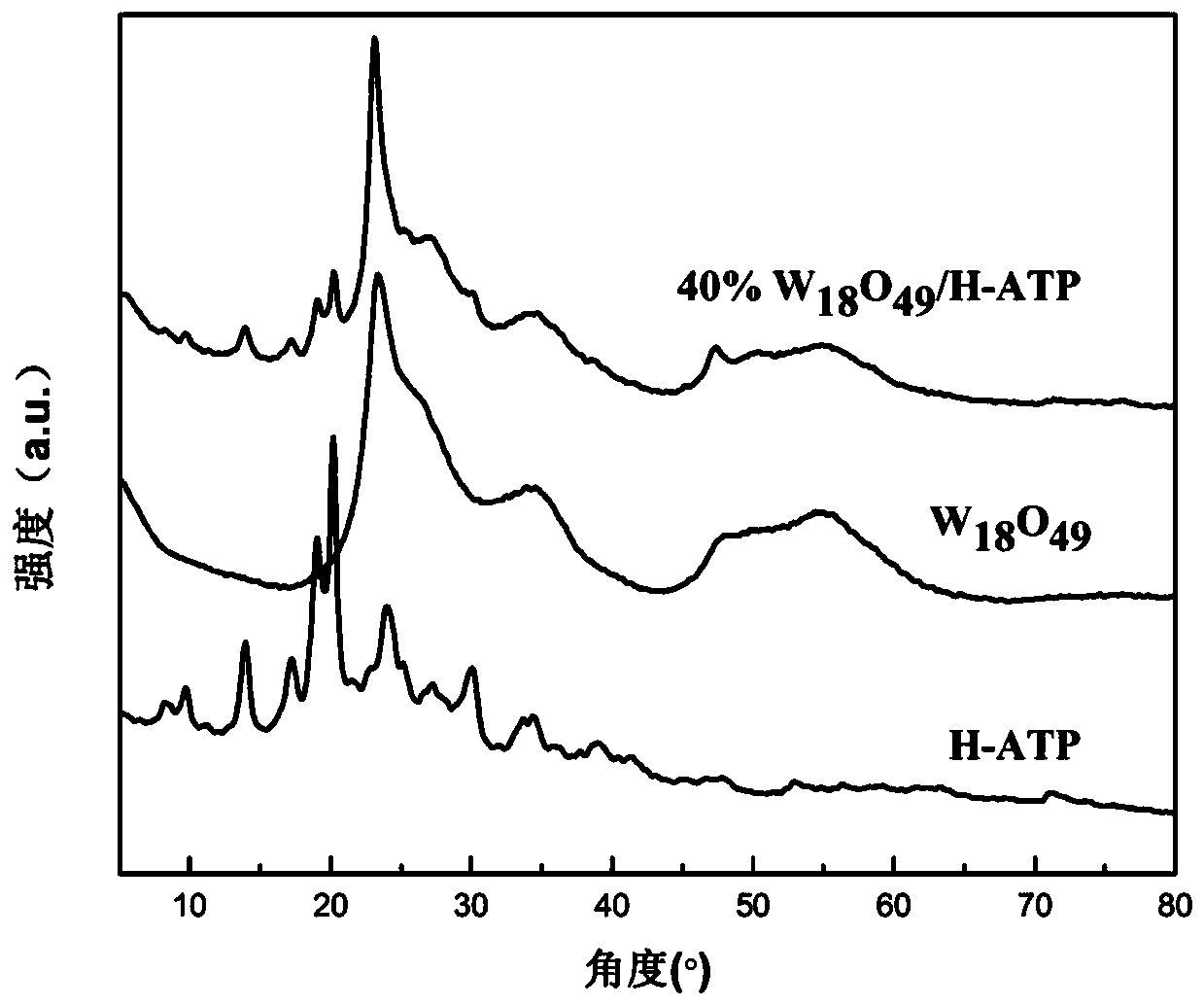

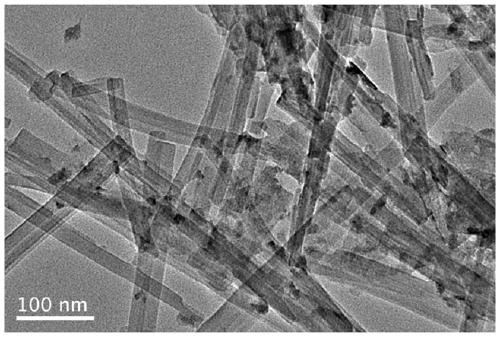

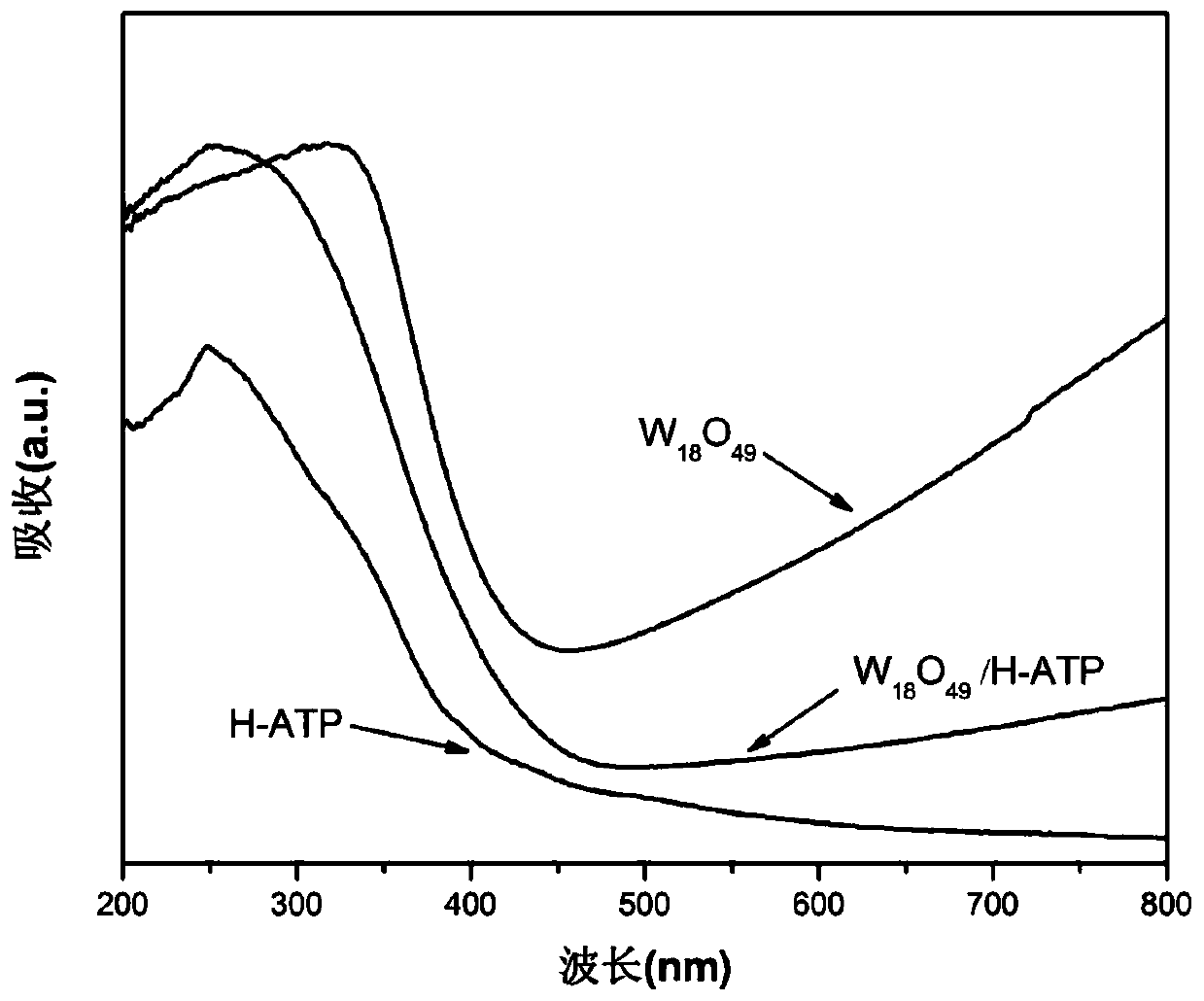

[0025] (1) First weigh 0.80g tungsten hexachloride (WCl 6 ), 1.20g of modified ATP was dissolved in 40ml of absolute ethanol solution, ultrasonically dissolved and then transferred to a 100ml microwave reactor for microwave solvothermal reaction, the set temperature was 180°C, and the time was 90min;

[0026] (2) Centrifuge the sample prepared in step (1), wash it three times with water and absolute ethanol, then dry the sample at 60°C for 24 hours, and grind it to obtain a tungsten oxide-modified attapulgite composite material 40%W 18 o 49 / ATP.

Embodiment 2

[0040] (1) First weigh 0.80g WCl 6 , 0.80g ATP was dissolved in 40ml of absolute ethanol solution, ultrasonically dissolved, transferred to a 100ml microwave hydrothermal kettle for microwave hydrothermal heating, set the temperature at 180°C, and the time was 90min;

[0041] (2) Centrifuge the sample prepared in step (1), wash it with water and absolute ethanol three times, then dry the sample and grind it to obtain a tungsten oxide-modified attapulgite composite material 50%W 18 o 49 / ATP, the follow-up detection is as in Example 1. Generate ammonia gas of about 123μmol / L.

Embodiment 3

[0043] (1) First weigh 0.80g WCl 6 , 1.87g ATP was dissolved in 40ml of absolute ethanol solution, ultrasonically dissolved and then transferred to a 100ml microwave hydrothermal kettle for microwave hydrothermal heating, the set temperature was 180°C, and the time was 90min;

[0044] (2) The sample prepared in step (1) was centrifuged with a centrifuge, washed with water and absolute ethanol three times, then the sample was dried and ground to obtain a tungsten oxide-modified attapulgite composite material 30%W 18 o 49 / ATP, the follow-up detection is as in Example 1. The ammonia gas generated is about 118μmol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com