Preparation method of graphene aerogel with high specific surface area and high compression strength

A technology of graphene airgel and high specific surface area, which is applied in the direction of airgel preparation, graphene, chemical instruments and methods, etc., can solve the problems of curbing the physical and chemical properties of single-layer graphene, achieve high specific surface area and simple process , the effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The chemical substance material used in the present invention is: graphite oxide, dehydrated alcohol, deionized water, ascorbic acid, dimethylformamide, and its preparation dosage is as follows: in g, mL, cm 3 is the unit of measurement.

[0023] Deionized water: H 2 O: 5000 mL±10 mL; graphite oxide: 0.0189 g±0.0001 g; ascorbic acid: C 6 h 8 o 6 : 0.0378 g ± 0.0001 g; dimethylformamide: C 3 h 7 NO: 0.7 mL±0.001mL; absolute ethanol: CH 3 CH 2 OH: 1000mL±10mL.

[0024] Selected chemical materials.

[0025] The chemical substances and materials used in the preparation should be selected and controlled for quality purity, concentration and content: graphite oxide: solid solid, carbon content 43.42%, hydrogen content 2.02%, oxygen content 54.56%; ascorbic acid: solid solid , purity 99.7%; absolute ethanol: liquid liquid, purity 99.7%; deionized water: liquid liquid, purity 99.99%; dimethylformamide: liquid liquid, purity 99.7%.

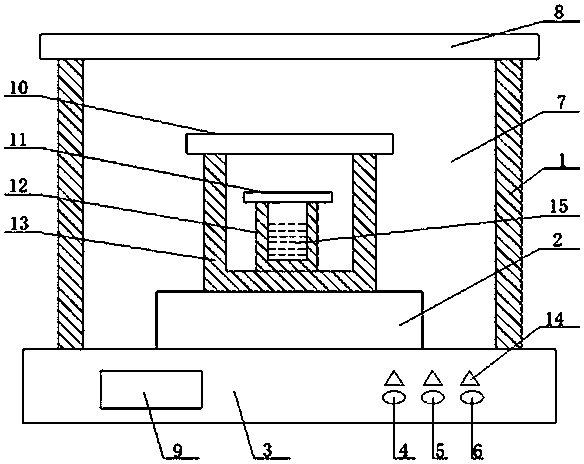

[0026] Such as figure 1 As shown, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Block density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com