Preparation method of long-acting phosphorus removal filler

A long-term, high-quality technology, applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of phosphorus removal efficiency and service life that cannot be further improved, so as to prevent secondary pollution and improve removal The effect of improving the efficiency and phosphorus removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

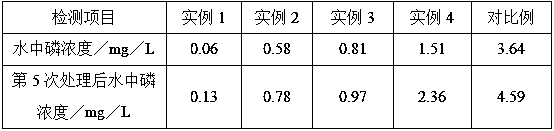

Examples

example 1

[0025] Mix polyallylamine hydrochloride and water in a beaker at a mass ratio of 1:40, and add sodium chloride 0.2 times the mass of polyallylamine hydrochloride to the beaker at a temperature of 40°C and a rotational speed of 400r / min Under the condition of stirring and mixing for 2 hours, polyallylamine hydrochloride solution was obtained; chitosan and acetic acid solution with a mass fraction of 5% were mixed in a mass ratio of 1:15, and the mixture of chitosan and mass hydrochloric acid solution Add iron ferric oxide with 2 times the quality of chitosan, mixed surfactant with 0.3 times the quality of chitosan and paraffin wax with 0.2 times the quality of chitosan, at a temperature of 60 °C and a rotating speed of 300r / min. After stirring and mixing for 40 minutes, the chitosan mixture was obtained. The chitosan mixture and the glutaraldehyde solution with a mass fraction of 20% were mixed at a mass ratio of 10:2, and the temperature was 65°C and the rotational speed was 32...

example 2

[0027] Mix polyallylamine hydrochloride and water in a beaker at a mass ratio of 1:40, and add sodium chloride 0.2 times the mass of polyallylamine hydrochloride to the beaker at a temperature of 40°C and a rotational speed of 400r / min Under the condition of stirring and mixing for 2 hours, polyallylamine hydrochloride solution was obtained; chitosan and acetic acid solution with a mass fraction of 5% were mixed in a mass ratio of 1:15, and the mixture of chitosan and mass hydrochloric acid solution Add the mixed surfactant of 0.3 times of the quality of chitosan and the paraffin of 0.2 times of the quality of chitosan, at the temperature of 60 ℃, under the condition of 300r / min, stirring and mixing for 40min to obtain the chitosan mixture, The chitosan mixture and the glutaraldehyde solution with a mass fraction of 20% were mixed at a mass ratio of 10:2, and then stirred and reacted for 2 hours at a temperature of 65°C and a rotational speed of 320r / min, and then heated at a t...

example 3

[0029]Mix polyallylamine hydrochloride and water in a beaker at a mass ratio of 1:40, and add sodium chloride 0.2 times the mass of polyallylamine hydrochloride to the beaker at a temperature of 40°C and a rotational speed of 400r / min Under the condition of stirring and mixing for 2 hours, polyallylamine hydrochloride solution was obtained; chitosan and acetic acid solution with a mass fraction of 5% were mixed in a mass ratio of 1:15, and the mixture of chitosan and mass hydrochloric acid solution Add iron ferric oxide with 2 times the quality of chitosan, mixed surfactant with 0.3 times the quality of chitosan and paraffin wax with 0.2 times the quality of chitosan, at a temperature of 60 °C and a rotating speed of 300r / min. After stirring and mixing for 40 minutes, the chitosan mixture was obtained. The chitosan mixture and the glutaraldehyde solution with a mass fraction of 20% were mixed at a mass ratio of 10:2, and the temperature was 65°C and the rotational speed was 320...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com