A kind of siderite modified sulfur light material and its preparation method and application

A light material, siderite technology, applied in applications, other household appliances, chemical instruments and methods, etc., can solve the problems of limited efficiency of nitrogen and phosphorus removal, difficulty in efficient application, increase of specific surface area, etc., to achieve easy microbial attachment , light weight and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A kind of preparation method of siderite modified sulfur light material of the present invention, comprises the following steps:

[0036] S1. Mix fine siderite with a particle size of ≤0.3 mm and sulfur at a mass ratio of 10:1 to 1:5, more preferably 3:1 to 1:2, and heat to 115 to 200°C, more preferably 140°C ~160°C, high-temperature melting to obtain a molten mixture of siderite and sulfur;

[0037] S2. Foaming the siderite and sulfur molten mixture obtained in step S1 by physical foaming or chemical foaming, cooling and molding to obtain a siderite modified sulfur light material, wherein the cooling molding method includes wet granulation, The steel belt is granulated or crushed and granulated after solidification.

[0038] Wet granulation means that the molten mixture of siderite and sulfur is dropped into water and cooled to form a solid material; steel belt granulation means that the molten mixture of siderite and sulfur is dropped on a steel belt and cooled to fo...

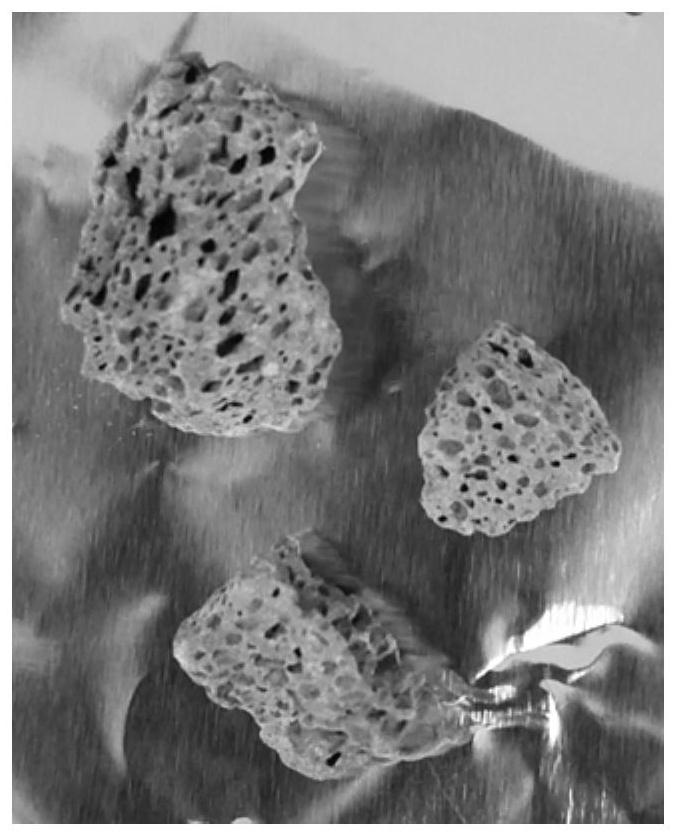

Embodiment 1

[0051] In this example, sulfur and siderite are uniformly mixed according to the mass ratio of 1:1, and the mixture is heated to 150°C for high-temperature melting to obtain a molten mixture of siderite and sulfur; under the condition of physical aeration, nitrogen is blown into the In the above-mentioned molten mixture, the siderite and sulfur molten mixture are foamed, and the molten mixture is mechanically stirred during the foaming process. The stirring speed is 200-300rpm, and the stirring time is 20 minutes, so that the bubbles are evenly dispersed in the molten mixture. In the mixture; finally cooled and formed to prepare the siderite modified sulfur light material, the obtained material is as figure 1 shown. The density of the siderite-modified sulfur light material prepared in this example is greater than that of water, measured to be about 2.13g / cm 3 , the porosity is 30.8%.

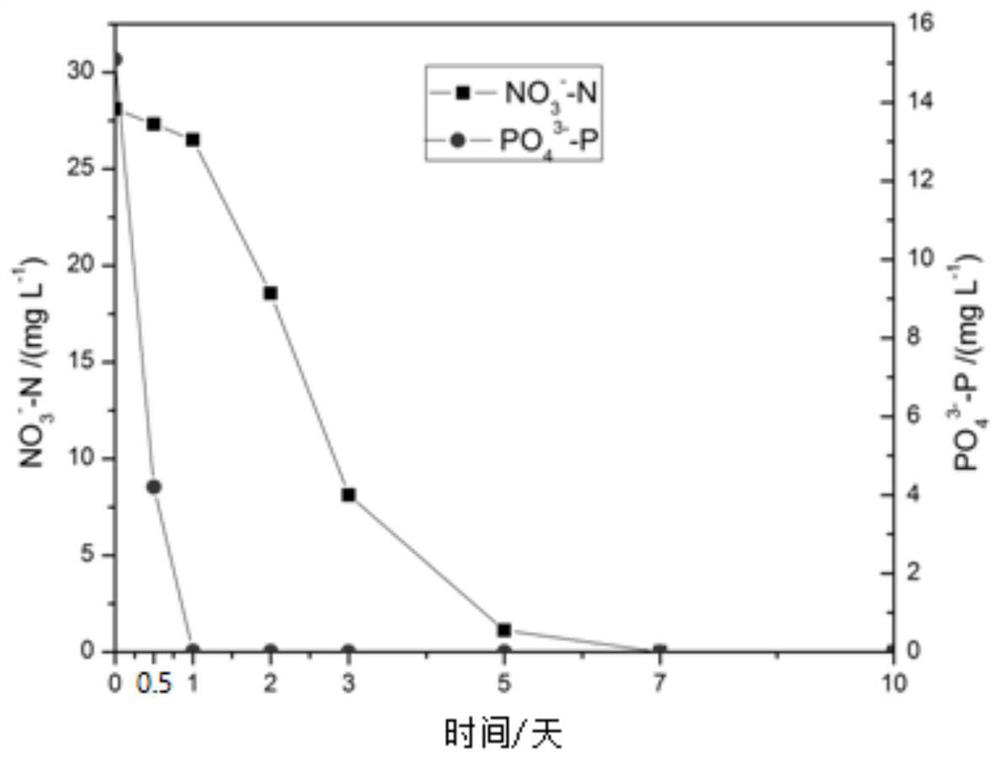

[0052] Take 10g of the crushed siderite modified sulfur light material and put it into th...

Embodiment 2

[0054] The basic content of this embodiment is the same as embodiment 1, and the difference is: the mass ratio of sulfur and siderite is 10:1 in the present embodiment; 95% of siderite quality and all sulfur are taken by weighing in the process of concrete mixing Mix to obtain a mixture, heat the mixture to 120°C for high-temperature melting to obtain a molten mixture of siderite and sulfur; at this mass ratio, the molten mixture of siderite and sulfur has a low viscosity, and it is necessary to add a chemical foaming agent, bicarbonate Sodium for foaming. Sulfur, siderite, foaming agent mass ratio is 300:30:2, the remaining 5% siderite is mixed with sodium bicarbonate, then the mixture of siderite and sodium bicarbonate is added to the above-mentioned siderite In the molten mixture of ore and sulfur, the molten mixture is magnetically stirred at the same time, the stirring speed is 50-100rpm, and the stirring time is 5 minutes; finally, it is cooled and formed to prepare the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com