Red mud concentration sedimentation method

A red mud and magnetic flocculant technology, applied in chemical instruments and methods, dewatering/drying/concentrating sludge treatment, sludge treatment, etc., can solve the problems of large amount of flocculant, organic pollution of red mud, and inability to recycle , to achieve the effect of low consumption and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

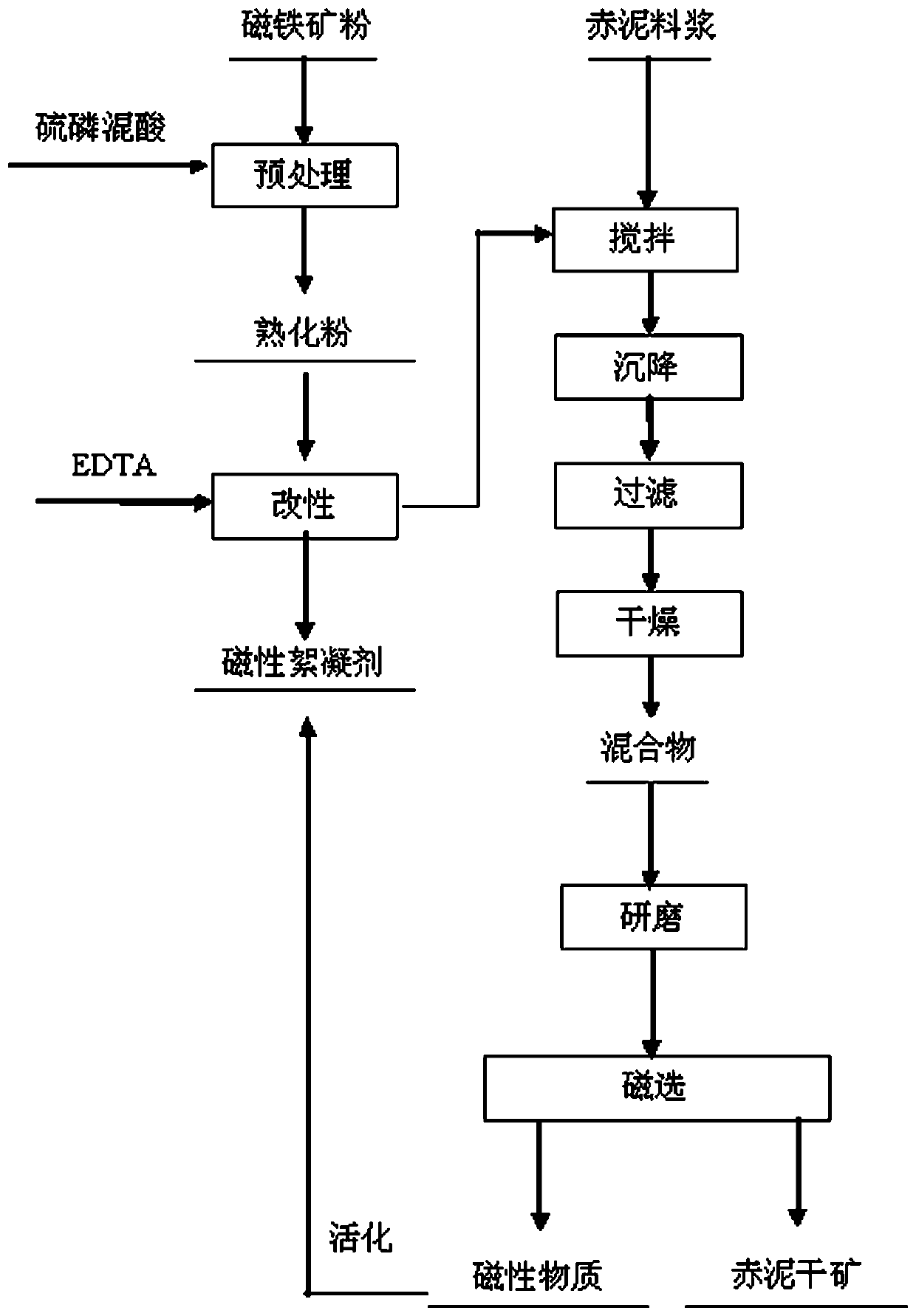

[0025] Mix concentrated sulfuric acid and concentrated phosphoric acid uniformly at a volume ratio of 7:3 to obtain sulfur-phosphorus mixed acid, then mix magnetite powder and sulfur-phosphorus mixed acid at a mass ratio of 30:70, and then place them in a high-temperature resistant pressurized leaching device. Mature at ℃ for 24 hours, cool to room temperature after curing, and obtain cured powder after solid-liquid separation, then mix the cured powder with EDTA at a mass ratio of 90:10, stir at 20~30°C for 10~12h, after stirring The magnetic flocculant is obtained through solid-liquid separation and is used for future use. Mix the magnetic flocculant and the red mud slurry according to the mass ratio of 1:99 and stir for 15 minutes. After the stirring is completed, let it settle for 10 minutes, discharge the upper clarified liquid, filter and dry the lower layer slurry to obtain a mixture, and grind the mixture Dry magnetic separation, the magnetic field strength is 50KA / m. ...

Embodiment 2

[0027] Mix concentrated sulfuric acid and concentrated phosphoric acid uniformly at a volume ratio of 8:2 to obtain sulfur-phosphorus mixed acid, then mix magnetite powder with sulfur-phosphorus mixed acid at a mass ratio of 40:60, and then place it in a high-temperature resistant pressurized leaching device. Mature at ℃ for 18 hours, cool to room temperature after curing, and obtain cured powder after solid-liquid separation, then mix the cured powder with EDTA at a mass ratio of 85:15, stir at 30-40°C for 8-10 hours, after stirring The magnetic flocculant is obtained through solid-liquid separation and is used for future use. Mix the magnetic flocculant and the red mud slurry according to the mass ratio of 3:97 and stir for 10 minutes. After the stirring is completed, let it settle for 10 minutes, discharge the upper clarified liquid, filter and dry the lower layer slurry to obtain a mixture, and grind the mixture Dry magnetic separation, the magnetic field strength is 30KA / ...

Embodiment 3

[0029]Mix concentrated sulfuric acid and concentrated phosphoric acid uniformly at a volume ratio of 9:1 to obtain sulfur-phosphorus mixed acid, then mix magnetite powder with sulfur-phosphorus mixed acid at a mass ratio of 50:50, and then place it in a high-temperature resistant pressure leaching device. Mature at ℃ for 15 hours, cool to room temperature after curing, and obtain cured powder after solid-liquid separation, then mix the cured powder with EDTA at a mass ratio of 80:20, stir at 40~50°C for 6~8h, after the stirring is completed The magnetic flocculant is obtained through solid-liquid separation and is used for future use. Mix the magnetic flocculant and the red mud slurry according to the mass ratio of 4:96 and stir for 5 minutes. After the stirring is completed, let it settle for 10 minutes, discharge the upper clarified liquid, filter and dry the lower layer slurry to obtain a mixture, and grind the mixture Dry magnetic separation, the magnetic field strength is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com