Halogen-free flame-retardant polycarbonate and preparation method thereof

A technology for flame retardant polycarbonate and polycarbonate, which is applied in chemical instruments and methods, organic chemistry, compounds of Group 5/15 elements of the periodic table, etc. Flame retardant and fire protection requirements, etc., to achieve the effect of suitable melting point, excellent flame retardant effect, and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The synthesis of halogen-free flame retardant DOPMI, its synthetic route is as follows:

[0023] .

[0024] (1) Add DOPO and THF into a four-neck flask, heat up to 80-100°C and stir;

[0025] (2) Infuse nitrogen gas into the four-necked flask, and after DOPO is completely dissolved, add 10-20% by mass of triphenylphosphine;

[0026] (3) Add N-PMI to tetrahydrofuran to prepare N-PMI solvent, and set it aside;

[0027] (4) Slowly add the prepared N-PMI solution dropwise into the four-necked flask at a certain temperature of 120-160°C, and continue to react for 2-3 hours after the addition is complete;

[0028] (5) After the reaction is completed, a fine sandy white solid is obtained after suction filtration, washing and drying, which is the halogen-free flame retardant of the present invention.

[0029] In a clean four-necked flask, add 15ml of tetrahydrofuran as an organic solvent, then add 2.16g of DOPO into a 100ml four-necked flask, heat up to 90°C and stir, and ...

Embodiment 2

[0033] Structural characterization and thermal performance analysis of halogen-free flame retardant DOPMI:

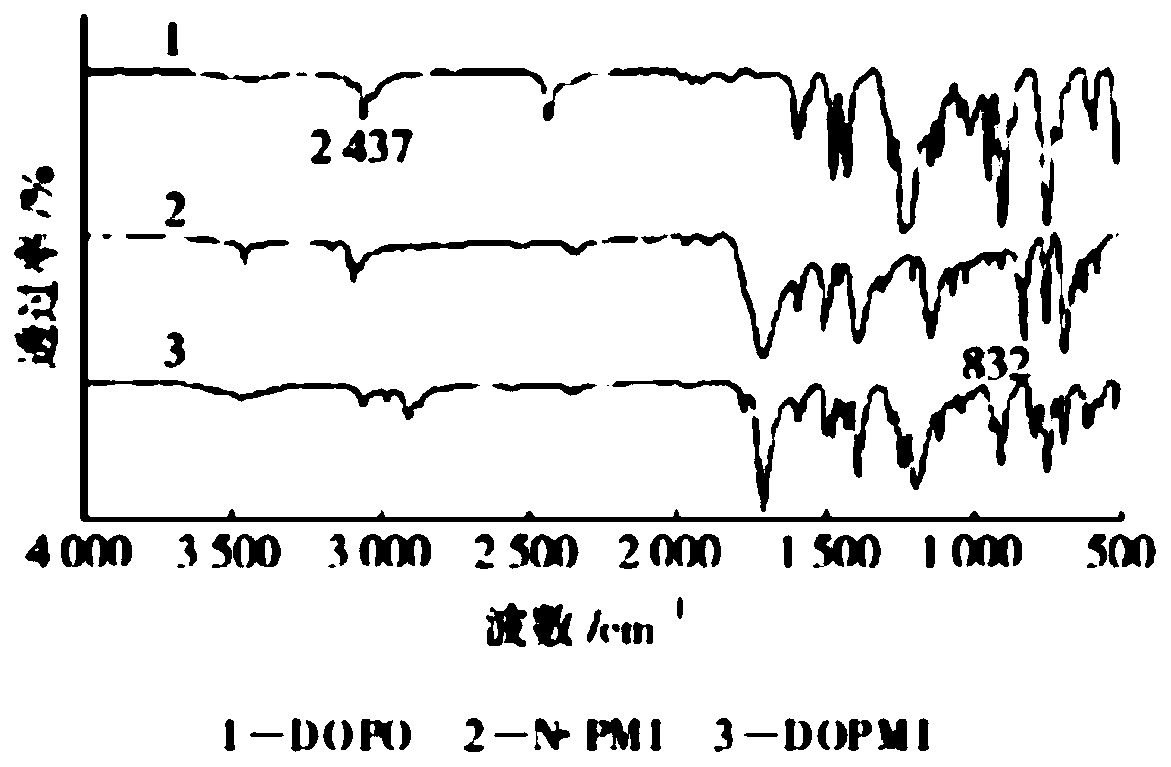

[0034] figure 1 FT-IR spectra of DOPO, N-PMI and DOPMI. From figure 1 It can be seen that the strong characteristic absorption peak 2437cm-1 of the P-H bond in DOPO disappears in the middle and late stages of DOPMI, and the strong conjugated double bond absorption peak 832cm-1 of N-PMI does not appear in the DOPMI spectrum, indicating that two had a reaction. It can be seen in the DOPMI spectrum that the absorption peak of Ar-H is at 3060cm-1, the characteristic peak of C=O is at 1712cm-1, the absorption peak of P-Ph is at 1594cm-1, and the absorption peak of P-Ph is at 1196cm-1. The OP-Ph absorption peak and the characteristic peaks characterize the structure of DOPMI, and the infrared slit results show that the expected reaction between DOPO and N-PMI occurred.

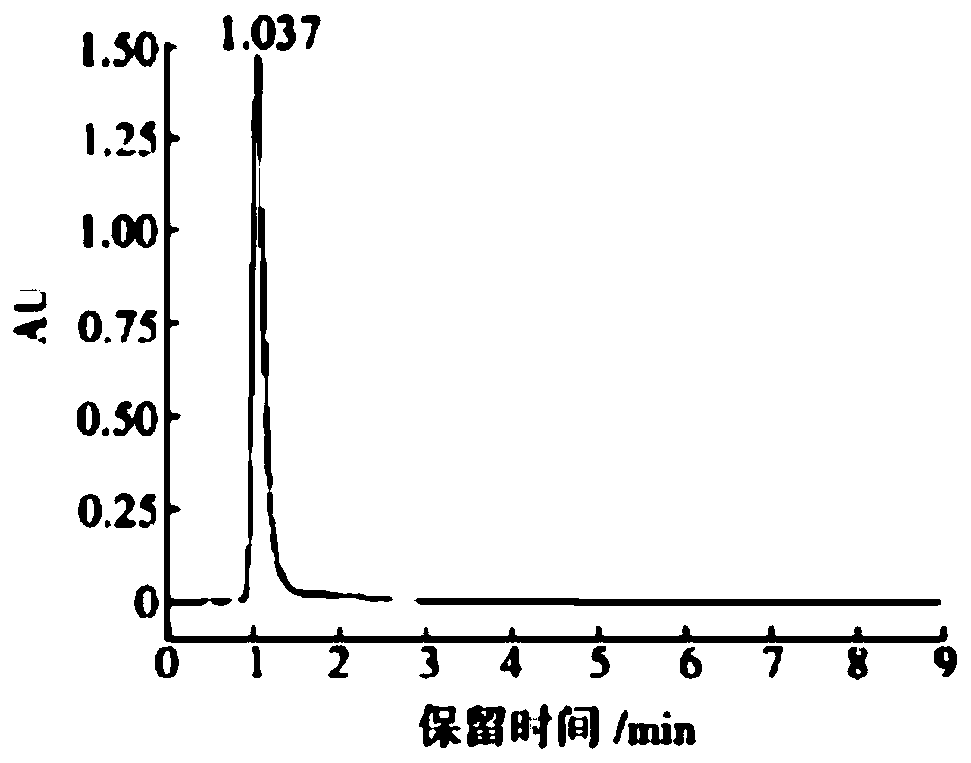

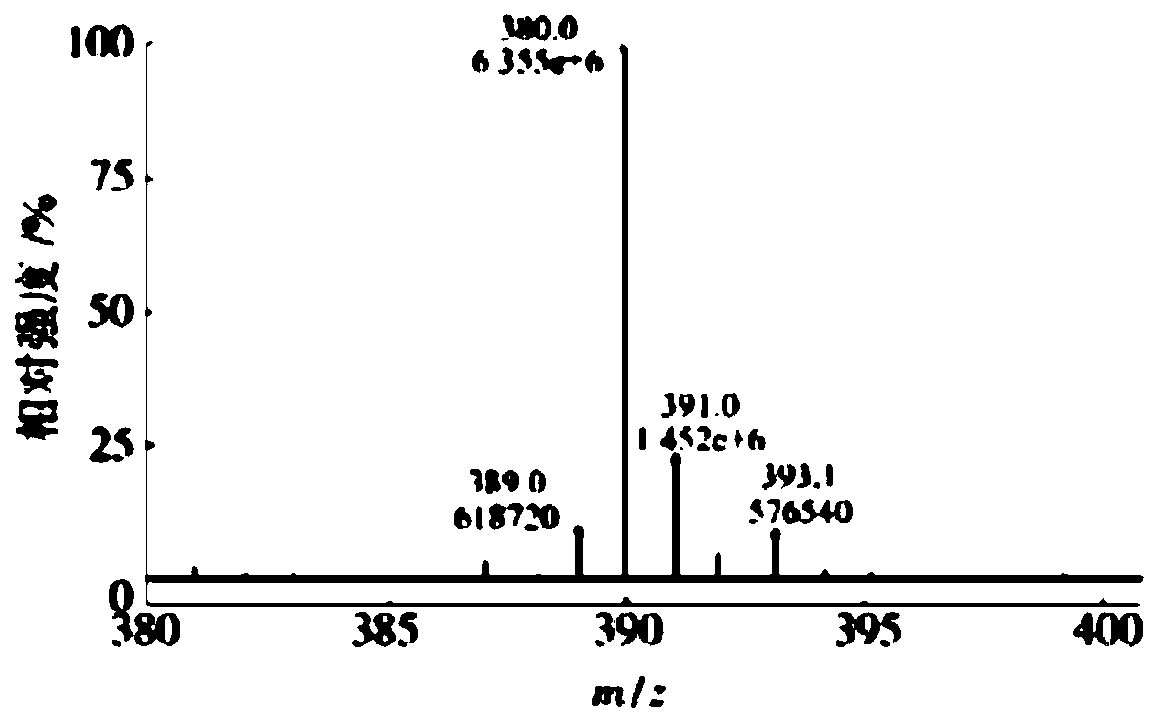

[0035] figure 2 and image 3 LC and MS spectra of DOPMI, respectively. From figure 2 It can be s...

Embodiment 3

[0038] (1) Synthesize DOPO and N-PMI in the organic solvent tetrahydrofuran, and obtain the fine sandy white solid halogen-free flame retardant DOPMI after suction filtration, washing and drying;

[0039] (2) After adding the DOPMI solid into the pulverizer and pulverizing it, put it in a blast drying oven with a temperature of 100-110°C and dry it for 6-8 hours;

[0040] (3) After mixing 3 parts by weight of DMPMI powder I, 24 parts by weight of phosphorus-containing flame-retardant PET, 2 parts by weight of MPS, and 1 part by weight of other additives, extrude in a screw extruder out and granulated to obtain the halogen-free flame-retardant polycarbonate of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com