A zero-carbon emission cogeneration device and working method based on full thermal cycle

A technology of cogeneration of cooling, heating and power, and thermal cycle, which is applied in steam engine installations, gas turbine installations, energy-saving heating/cooling, etc., and can solve problems such as low power generation efficiency, pollution, and failure to consider a large amount of cold energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above objects, characteristics and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

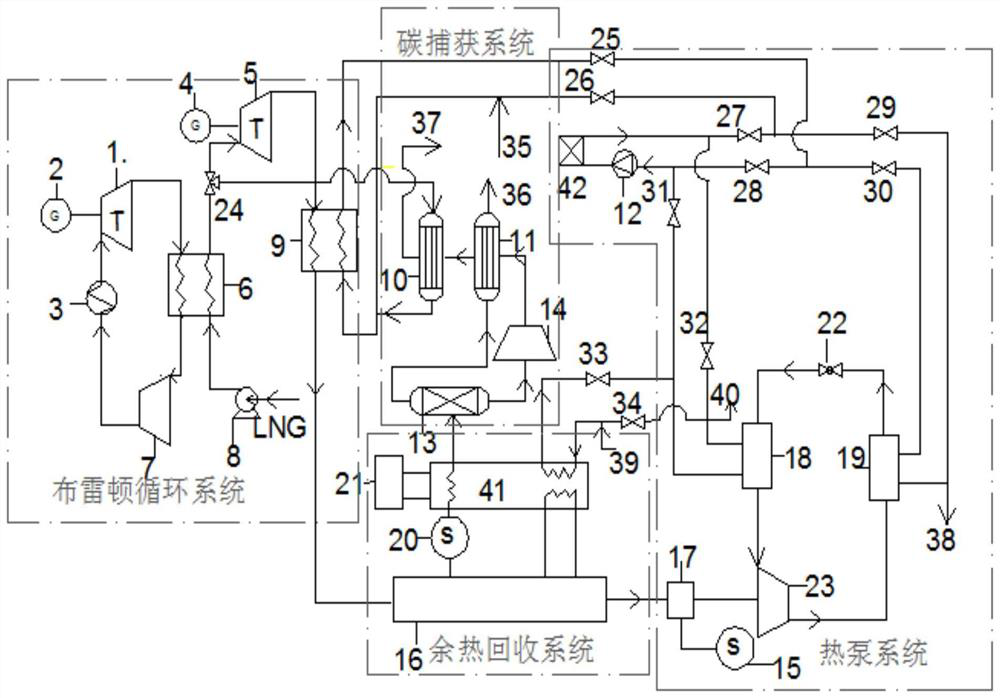

[0034] Such as figure 1 As shown, it is a zero-carbon emission cogeneration device based on a full thermal cycle of the present invention, including four parts: a Brayton cycle system, a waste heat recovery system, a carbon capture system and a heat pump system, wherein the Brayton The circulation system includes: LNG pump 8, first heat exchanger 6, compressor 7, reheater 3, first turboexpander 1, first generator 2, second turboexpander 5, second generator 4. The three-way valve 24, the second heat exchanger 9, the LNG pump 8 is connected to the lower right interface of the first heat exchanger 6, and the upper right interface of the first heat exchanger 6 is connected to the lower right interface of the three-way valve 24 interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com