Al2O3-ZrO2-Y2O3-TiN nano composite ceramic powder and preparation method thereof

A ceramic powder and nano-composite technology, which is applied in chemical instruments and methods, zirconium compounds, inorganic chemistry, etc., can solve the problems of local component segregation and unsatisfactory mechanical properties of composite ceramic materials, and achieve good dispersion, Good hardness and wear resistance, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides the Al described in the above technical scheme 2 o 3 -ZrO 2 -Y 2 o 3 -The preparation method of TiN nanocomposite ceramic powder, comprises the following steps:

[0026] (1) Mix organic salts of aluminum salt, zirconium salt, yttrium salt and titanium salt in an organic solvent, add ammonia water to carry out hydrolysis reaction, and obtain a hydrolysis reaction product;

[0027] (2) After the hydrolysis reaction product obtained in the step (1) is subjected to solid-liquid separation, the solid is dried to obtain an intermediate product powder;

[0028] (3) The intermediate product powder obtained in the step (2) is subjected to gradient calcination to obtain Al 2 o 3 -ZrO 2 -Y 2 o 3 -Ti 2 O solid solution;

[0029] (4) The solid solution obtained in the step (3) is subjected to selective nitriding reaction under ammonia gas to obtain Al 2 o 3 -ZrO 2 -Y 2 o 3 -TiN nanocomposite ceramic powder; the temperature of the s...

Embodiment 1

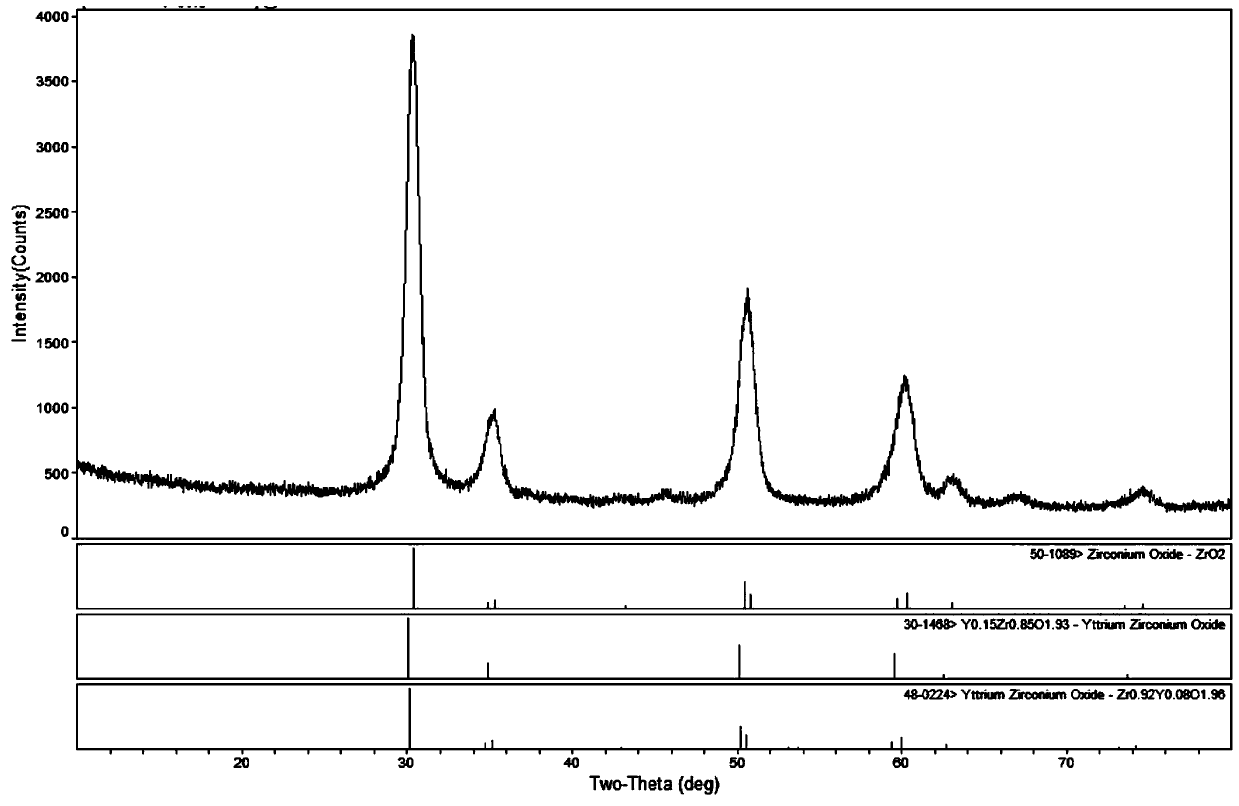

[0041] Aluminum isopropoxide (C 9 h 21 AlO 3 ), zirconium n-propoxide (C 12 h 28 o 4 Zr), yttrium isopropoxide (C 9 h 21 o 3 Y) and isopropyl titanate (C 12 h 28 o 4 Ti) as raw material, according to molar ratio ZrO 2 :Y 2 o 3 =98.5:1.5, ZrO 2 :Al 2 o 3 :TiO 2 =60:25:15 Weigh the raw materials, 19.65 grams of zirconium n-propoxide, 10.2 grams of aluminum isopropoxide, 4.26 grams of isopropyl titanate, and 0.486 grams of yttrium isopropoxide. It was dissolved in isopropanol, left for two hours, ammonia water was added as a precipitating agent, and then refluxed at a temperature of 78° C. for 24 hours to obtain a hydrolyzed product. The hydrolyzate was centrifuged and the resulting solid washed with hot water. Then the washed solid was dried in vacuum at 120° C. to obtain an intermediate product (powder).

[0042] The obtained intermediate product (powder) was calcined in air at 700°C for 9 hours, and then calcined in high-temperature air at 900°C for 3 hours ...

Embodiment 2

[0049] Aluminum isopropoxide (C 9 h 21 AlO 3 ), zirconium n-propoxide (C 12 h 28 o 4 Zr), yttrium isopropoxide (C 9 h 21 o 3 Y) and isopropyl titanate (C 12 h 28 o 4 Ti) as raw material, according to molar ratio ZrO 2 :Y 2 o 3 =98.5:1.5, ZrO 2 :Al 2 o 3 :TiO 2 =80:15:5 Weigh the raw materials, 26 grams of zirconium n-propoxide, 6 grams of aluminum isopropoxide, 1.4 grams of isopropyl titanate, and 0.646 grams of yttrium isopropoxide. It was dissolved in isopropanol, left for two hours, ammonia water was added as a precipitating agent, and then refluxed at a temperature of 78° C. for 24 hours to obtain a hydrolyzed product. The hydrolyzate was centrifuged and the resulting solid washed with hot water. Then the washed solid was dried in vacuum at 120° C. to obtain an intermediate product (powder).

[0050] The obtained intermediate product (powder) was calcined in air at 700°C for 9 hours, and then calcined in high-temperature air at 900°C for 3 hours to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com