Solid catalyst component and catalyst system for olefin polymerization, and olefin polymerization method

A solid catalyst, olefin polymerization technology, applied in the field of olefin polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

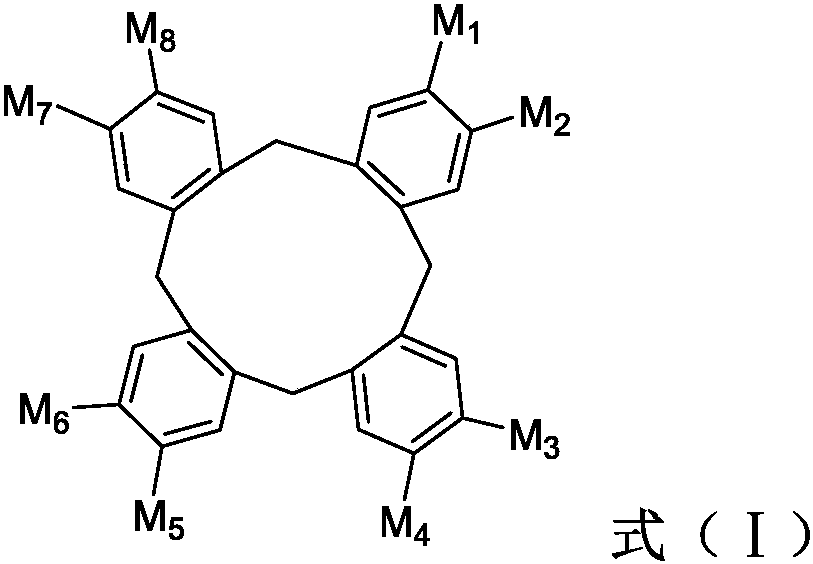

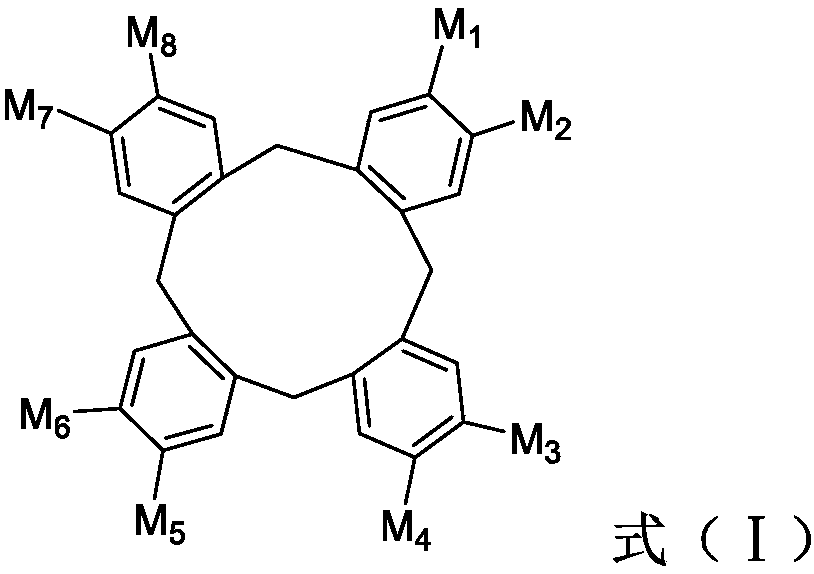

Method used

Image

Examples

Embodiment approach

[0069] According to a preferred embodiment, the magnesium alkoxide compound is selected from Mg(OEt) 2 and / or Mg(OEt) a (OEHA) 2-a (1.5≤a<2).

[0070] Generally, the general formula of the titanium compound is Ti(OR) n x 4-n , where R is C 1 -C 8 Hydrocarbyl, preferably C 1 -C 8 Alkyl, X is a halogen atom, preferably fluorine, chlorine, bromine, 0≤n≤4. For example, the titanium compound may be selected from TiCl 4 、TiBr 4 、TiI 4 , Ti(OC 2 h 5 )Cl 3 , Ti(OCH 3 )Cl 3 , Ti(OC 4 h 9 ) Cl 3 , Ti(OC 2 h 5 )Br 3 , Ti(OC 2 h 5 ) 2 Cl 2 , Ti(OCH 3 ) 2 Cl 2 , Ti(OCH 3 ) 2 I 2 , Ti(OC 2 h 5 ) 3 Cl, Ti(OCH 3 ) 3 Cl, Ti(OC 2 h 5 ) 3 I, Ti(OC 2 h 5 ) 4 , Ti(OC 3 h 7 ) 4 and Ti(OC 4 h 9 ) 4 At least one of; preferably TiCl 4 , Ti(OC 2 h 5 )Cl 3 , Ti(OCH 3 )Cl 3 , Ti(OC 4 h 9 ) Cl 3 and Ti(OC 4 h 9 ) 4 At least one of, more preferably TiCl 4 .

[0071] Calculated per mole of magnesium, the titanium compound is used in an amount of ...

preparation example 1

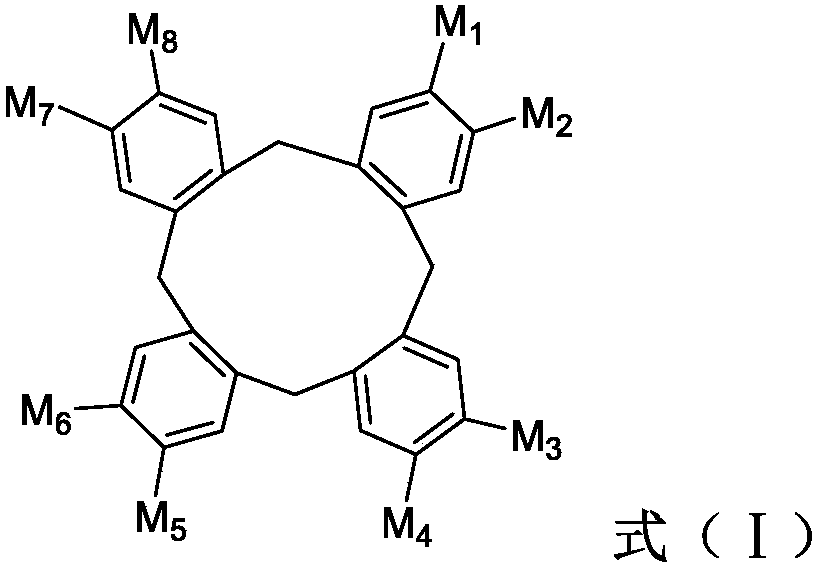

[0107] Preparation Example 1 is used to illustrate the preparation method of the cyclotetraveratrol and its derivatives.

[0108] Preparation Example 1

[0109] 3,4-Dimethoxybenzyl alcohol (5g) / dichloromethane (20mL) mixed solution was added dropwise to trifluoroacetic acid (25mL) in dichloromethane (200mL) solution, after the addition was completed, continue to The reaction was carried out for 4 hours. The reaction was neutralized with sodium hydroxide solution, the organic phase was separated and completely sucked dry. The resulting product was washed several times with water and an organic solvent, and recrystallized in chloroform (80 mL) / benzene (30 mL) to obtain 2.5 g of compound A represented by formula (III). (Refer to Macromolecules1991, 24, 3227-3234)

[0110]

Embodiment 1

[0113] (1) Preparation of solid catalyst component

[0114] 10g Mg(OEt) 2 1. 55mL of toluene was added into the reaction kettle, and a suspension was formed under the condition of a stirring rate of 300rpm. The system was cooled down to 0°C, and 30mL of titanium tetrachloride and 0.2g of cycloveratrolene (compound A) were slowly added successively. After the addition was completed, the temperature was slowly raised to 90°C, and the temperature was kept constant for 1.5 hours. Stop stirring and let it stand, the suspension will be layered quickly, and the supernatant will be removed. Add 60 mL of toluene and 30 mL of titanium tetrachloride, raise the temperature to 90°C, and keep the temperature constant for 2 hours. Stop stirring, let it stand, and remove the supernatant. After repeated washing with toluene and hexane and drying, a solid catalyst component with good fluidity was obtained, and its composition is shown in Table 1.

[0115] (2) homopolymerization reaction

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com