Method of producing rutile titanium dioxide by sulfuric acid method and preparation method of double-effect seed crystal used

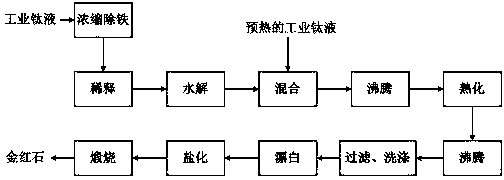

A technology of rutile titanium dioxide and double-effect seed crystals, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of long process, complicated industrial application and difficulties of the double-effect seed crystal method, and achieve the best industrial application prospects, The effect of high crystal conversion activity and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

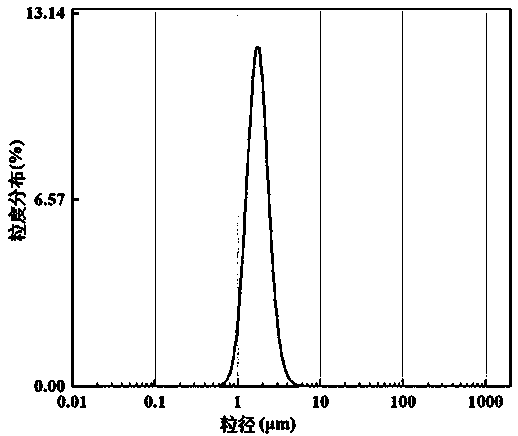

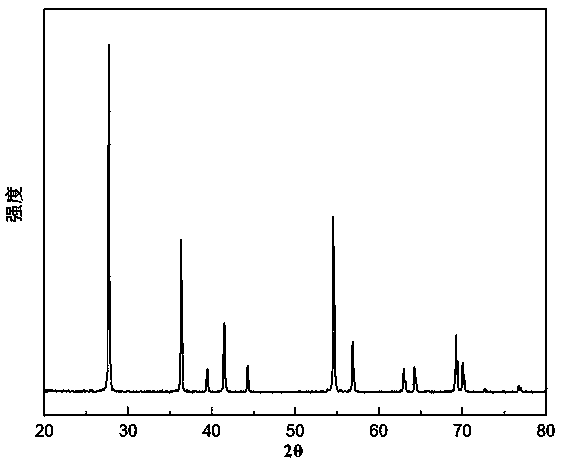

[0035] Dilute the industrial titanium liquid to 30g / L, heat it through continuous coil equipment for 60s, and the outlet temperature is 96°C to obtain 1# seed crystal suspension. Take 50ml of industrial titanium solution with a concentration of 210g / L, an iron-titanium ratio of 0.25, and an F value of 1.9 in a three-necked flask, stir and heat, and after the titanium solution is heated to 96°C, add TiO 2 Add 2wt% of the prepared 1# seed crystal suspension, heat and stir for 10 minutes, and then heat up to boiling. After the hydrolyzate turns gray, stop heating and stirring immediately and mature for 30 minutes, then restart heating and stirring and heat up to boiling. After boiling for 50 minutes, add dilution water to adjust the concentration of the titanium solution to 160-170g / L, and continue boiling for 2.5 hours to end the hydrolysis, filter and wash the hydrolyzed slurry, and the measured hydrolysis rate reaches 96%. The filter cake was calcined at 850°C for 80 min, and...

Embodiment 2

[0037] Dilute the industrial titanium solution to 40g / L, and heat it through continuous coil equipment for 80s with an outlet temperature of 98°C to obtain 2# seed crystal suspension. Take 50ml of industrial titanium solution with a titanium solution concentration of 210g / L, an iron-to-titanium ratio of 0.25, and an F value of 1.9 in a three-necked flask, stir and heat, and after the titanium solution is heated to 96°C, add TiO 2 Add 2wt% of the prepared 2# seed crystal suspension, heat and stir for 10 minutes, and then heat up to boiling. After the hydrolyzate turns gray, stop heating and stirring immediately and mature for 30 minutes, then restart heating and stirring and heat up to boiling. Add dilution water after boiling for 50 minutes, adjust the concentration of titanium solution to 160-170g / L, and stop hydrolysis after boiling for 2.5 hours, filter and wash the hydrolyzed slurry, and measure the hydrolysis rate to reach 95%. The filter cake was calcined at 930°C for 3...

Embodiment 3

[0039] The laboratory made 20g / L titanium liquid, heated it through continuous coil equipment for 200s, and the outlet temperature was 90°C to obtain 3# seed crystal suspension. Take 50ml of industrial titanium solution with a concentration of 150g / L, iron-titanium ratio2 Add 0.5wt% of the prepared 3# seed crystal suspension, heat and stir for 15 minutes, and then heat up to boiling. After the hydrolyzate turns gray, stop heating and stirring immediately and mature for 20 minutes, then restart heating and stirring and heat up to boiling. After boiling for 50 minutes, add dilution water to adjust the concentration of the titanium solution to 130-170g / L, and continue boiling for 70 minutes to end the hydrolysis, filter and wash the hydrolyzed slurry, and measure the hydrolysis rate to reach 97%. The filter cake was calcined at 950°C for 120 min, and after calcining, it was ground and then measured by XRD. It was detected that the rutile content was 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com