Application of a mbr process in domestic sewage treatment

A domestic sewage and sewage technology, which is applied in biological water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low water flux and reduced sewage treatment efficiency, and achieve a firm combination and high Efficient sewage treatment process, the effect of improving water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

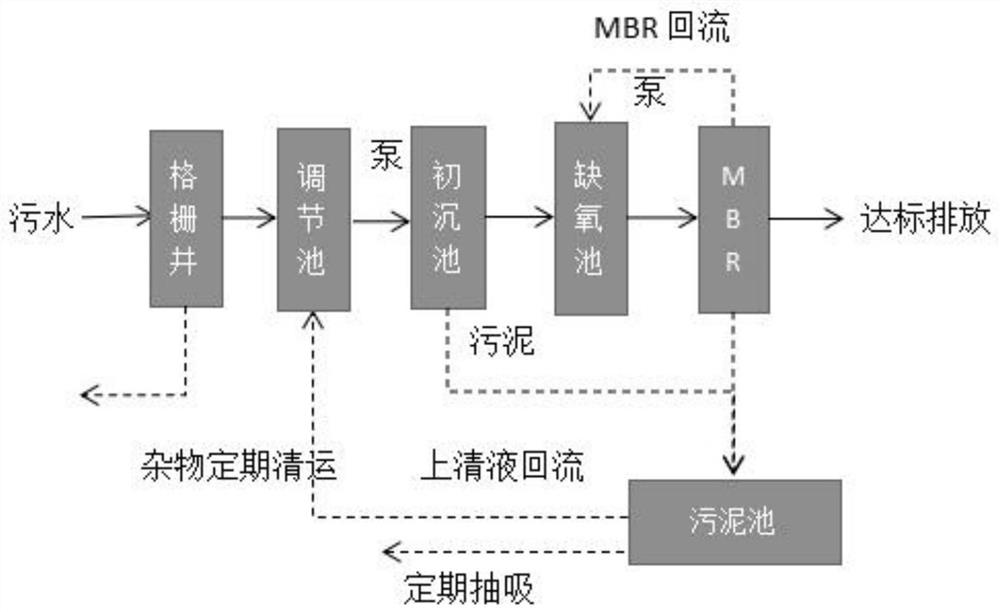

[0024] Application of a kind of MBR process in domestic sewage treatment, such as figure 1 As shown, the specific process is as follows:

[0025] In the first step, the sewage flows through the mechanical grille, and the mechanical grille automatically removes large particles of suspended solids and impurities in the sewage;

[0026] In the second step, the sewage treated in the first step flows into the sewage regulating tank, and the water quality and water quantity are adjusted in the regulating tank, and the sewage treated in the regulating tank is lifted to the primary sedimentation tank by the sewage lifting pump;

[0027] In the third step, polyaluminum chloride is added to the primary sedimentation tank, and phosphorus in the sewage is removed through polyaluminum chloride, and the sewage treated in the primary sedimentation tank flows to the anoxic tank by itself, and the organic nitrogen content in domestic sewage is high. During biodegradation, it will appear in th...

Embodiment 2

[0032] The membrane separation equipment in the MBR pool uses a flat membrane, and the filter membrane used in the flat membrane is a modified filter membrane, and the specific preparation process of the modified filter membrane is as follows:

[0033]Step 1: Weigh 980g of maleic anhydride and 5kg of p-toluenesulfonic acid into the reaction kettle, add 620g of ethylene glycol into it at the same time, raise the temperature to 200-220°C for 8-9h under reflux to obtain an unsaturated polyester solution, and then put Cool 1kg of unsaturated polyester solution to 90-95°C, and add 208g of benzoyl peroxide to it, stir and mix evenly, then add 163g of trifluoroethyl acrylate and 231g of 3-allyloxy-2 -Hydroxy-1-propanesulfonic acid sodium salt, stirring vigorously while adding dropwise, after the dropwise addition is complete, raise the temperature to 120-125°C for reflux reaction for 6-8h to obtain the stock solution;

[0034] Step 2: Mix 1 kg of the stock solution prepared in step 1...

Embodiment 3

[0037] The specific preparation process of the modified filter membrane is as follows:

[0038] Step 1: Weigh 980g of maleic anhydride and 5kg of p-toluenesulfonic acid into the reaction kettle, add 620g of ethylene glycol into it at the same time, raise the temperature to 200-220°C for 8-9h under reflux to obtain an unsaturated polyester solution, and then put 1kg of unsaturated polyester solution was cooled to 90-95°C, and 208g of benzoyl peroxide was added thereto, stirred and mixed evenly, and then 163g of trifluoroethyl acrylate was added dropwise to the reaction kettle, stirring vigorously while adding, dropping After the addition is complete, raise the temperature to 120-125°C for reflux reaction for 6-8 hours to obtain the stock solution;

[0039] Step 2: Mix 1 kg of the stock solution prepared in step 1 with 210 g of dipropylene glycol butyl ether and 160 g of dodecanol to obtain a casting solution, and the obtained casting solution is rolled into a film in a mold, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com