A kind of production process and application of fermented cassava starch for baking

A cassava starch and baking technology, which is applied in the directions of fermentation, application, and treatment of microorganisms with electricity/wave energy, can solve problems such as differences in product quality, irregular fermentation process conditions, and poor product stability, achieving short production cycles and eliminating Multi-strain mixed toxin risk, effect of improving gel structure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Use molasses (calculated according to available glucose content) to prepare a fermentation medium with a content of 0.5g / 100g, sterilize under high temperature and high pressure, control the temperature range at 115°C, control the pressure range at 0.2MPa, and control the sterilization time at 20min.

[0059] (2) The medium of the seed solution is a lactobacillus medium (MRS broth medium), the strain is Lactobacillus plantarum (CCTCCM2017138), the fermentation temperature is 37° C., and the fermentation time is 12 hours. After the temperature of the fermentation medium is lowered to 25°C, add tapioca starch in a clean environment. 10% of the mass. The fermentation temperature is 37° C., and the fermentation time is 96 hours.

[0060] (3) Wash the starch milk until the pH is 5 after the fermentation is finished. Adjust the water content of the fermented tapioca starch base to 50%.

[0061] (4) Spread the starch milk after the moisture adjustment on the drying con...

Embodiment 2

[0063] Referring to Example 1, the addition amount of molasses (calculated according to the available glucose content) is replaced by 0g / 100g, 1.0 g / 100g, 1.5g / 100g, 2.0g / 100g respectively, and other conditions are constant, and fermented tapioca starch is prepared . The production time of the whole process is 5 days. The performance results of the resulting product are shown in Tables 1, 2, and 3.

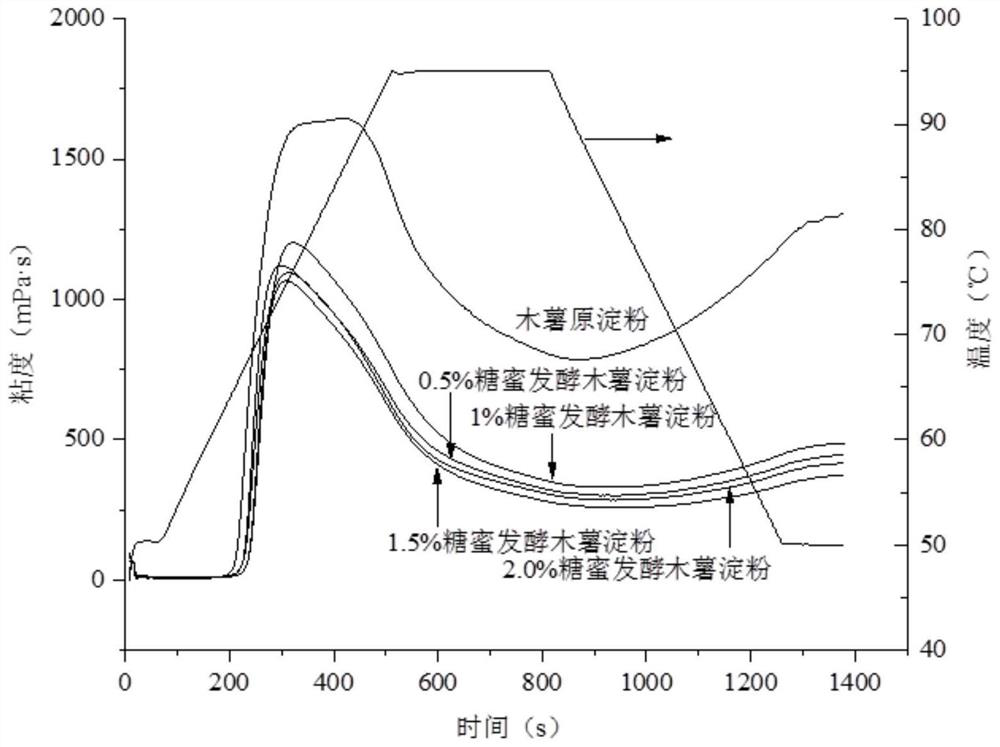

[0064] The gelatinization viscosity characteristics of fermented cassava starch obtained with different amounts of carbon sources were measured, and the results are shown in Table 1. It can be seen from Table 1 that compared with the original starch, the peak viscosity, valley viscosity, final viscosity and retrogradation value of cassava starch after fermentation and light decreased significantly, from 1651 mPa s, 796.5 mPa s, 1301.0 mPa s and 504.5 mPa s, respectively. mPa·s drops to around 1100mPa·s, 300mPa·s, 450mPa·s and 150mPa·s. Its disintegration value changes little, a...

Embodiment 3

[0074] (1) Use molasses (calculated according to available glucose content) to prepare a fermentation medium with a content of 1.0g / 100mL, sterilize under high temperature and high pressure, control the temperature range at 115°C, control the pressure range at 0.2MPa, and control the sterilization time at 20min.

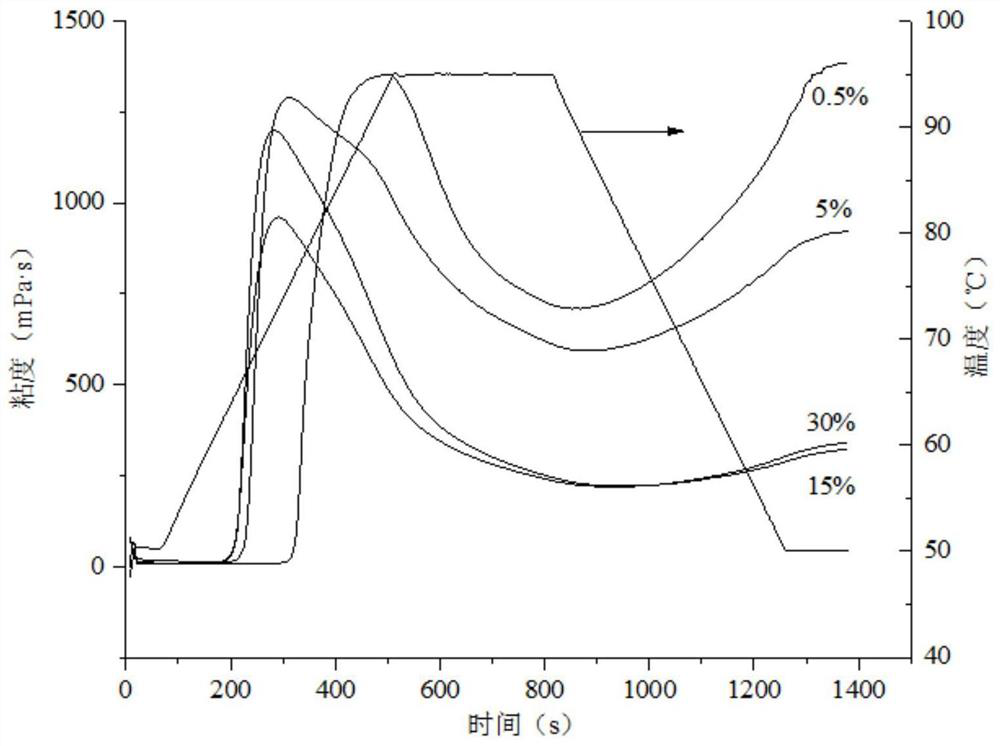

[0075] (2) The medium of the seed liquid is a lactic acid bacteria medium (MRS broth medium), the strain is Lactobacillus plantarum (CCTCCM2017138), the fermentation temperature is 37°C, and the fermentation time is 12h; after the fermentation medium is cooled to 25°C , add cassava starch in a clean environment, the addition amount is 50% of the mass of the medium, stir to prepare starch milk, transfer the fermented seed liquid into the fermentation medium, and replace the inoculum with 0.5% and 5% of the mass of starch milk respectively , 15%, 30%, the fermentation temperature is 37°C, and the fermentation time is 96h.

[0076] (3) After the fermentation, the starc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com