A kind of ink-jet printing pretreatment agent and the surface pretreatment method of silk fabric

A technology of surface pretreatment and pretreatment agent, applied in the field of textile printing and dyeing, can solve the problems of poor effect and high permeability of dye molecules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In this example, anionic polyacrylamide with a molecular weight of 12 million and high ionicity is used.

[0054] 5g of urea and 1g of sodium bicarbonate were rapidly dissolved in quantitative distilled water under the stirring action of agitator RW20, the obtained solution was stirred by agitator RW20 with a rotating speed of 350r / min, and 2g of polyacrylamide pretreatment agent was added while stirring, Seal and stand overnight to obtain a surface pretreatment agent with a concentration of 2%.

[0055] Using the horizontal rolling mill P-B0, pad the prepared surface pretreatment agent on the silk fabric that has been cut in advance, carry out one padding and one rolling pretreatment, and control the rolling ratio to be controlled at 100. . The fabric of the padding modified working solution was placed and dried in an oven at 75° C. to obtain a pretreated silk fabric.

Embodiment 2~6

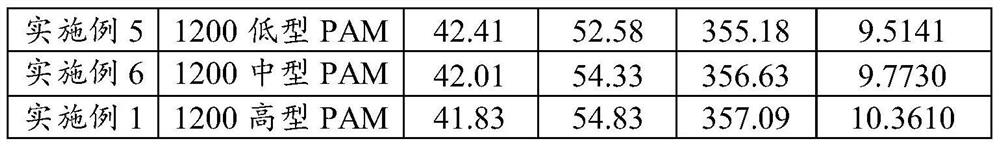

[0073] The silk fabric was pretreated according to the method in Example 1. The difference is that the molecular weight and ionicity of the polyacrylamide in Examples 2 to 6 are different from those in Example 1. Please refer to Table 4 for details.

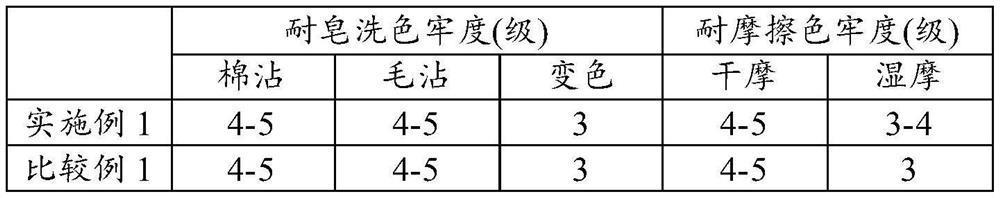

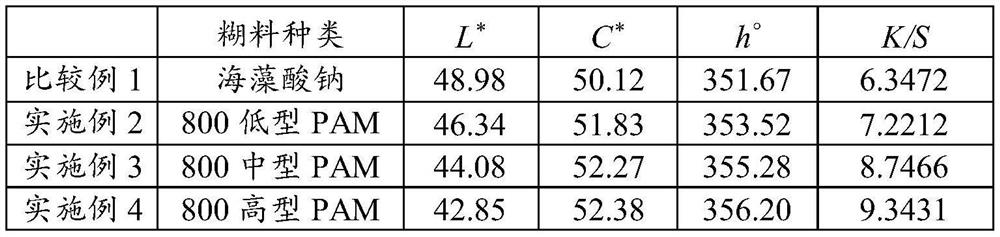

[0074] The pretreated silk fabrics in Examples 1 to 6 and Comparative Example 1 were subjected to the same batch of inkjet printing, and the inkjet printing performance was measured. The results are shown in Table 4.

[0075] Table 4 Influence of surface modifiers with different ionic degrees on the effect of reactive dye inkjet printing

[0076]

[0077]

[0078] Note: 800 represents 8 million molecular weight, and 1200 represents 12 million molecular weight. Low, medium and high respectively represent the ionicity of anionic polyacrylamide macromolecules.

Embodiment 7~12

[0080] The silk fabric was pretreated according to the method in Example 1. The difference is that the mass concentration of polyacrylamide in Examples 7-12 is different from that in Example 1. Please refer to Table 5 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com