Paper dry strength agent, preparation method of paper dry strength agent and application of paper dry strength agent

A technology of dry strength agent and paper, applied in the directions of paper, reinforcing agent addition, papermaking, etc., can solve the problems of decreased paper strength index, low paper stiffness, poor ring compressive strength, etc., and achieves increased paper strength and filler retention. The effect of improvement, water filtration improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

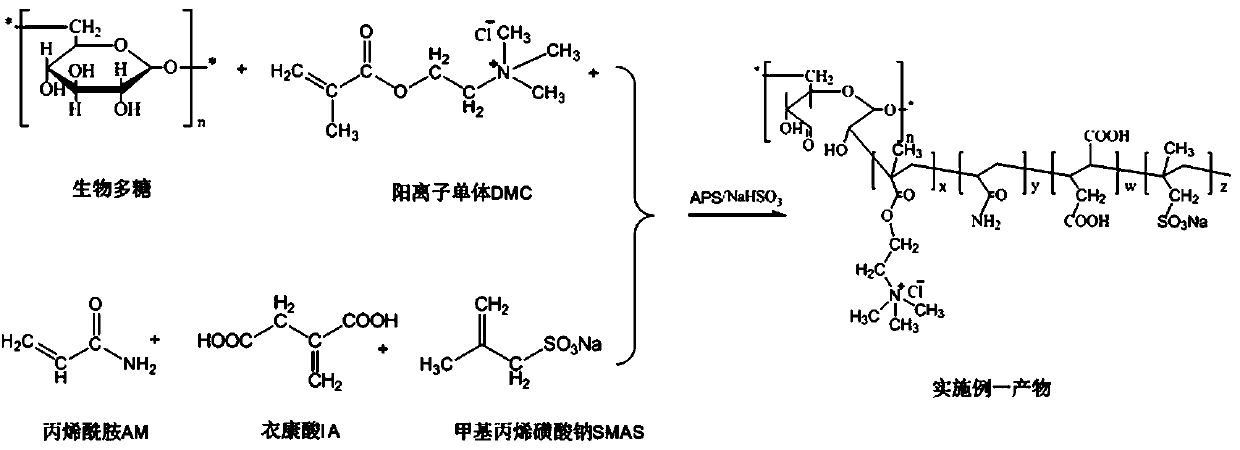

Embodiment 1

[0052] The radical initiator that embodiment 1, embodiment 4 and embodiment 5 adopt is the composition of ammonium persulfate / sodium bisulfite, and the mol ratio of ammonium persulfate and sodium bisulfite is respectively 1:1, 2:1 , 4:1;

[0053] The product can be used as paper dry strength agent for papermaking, etc.

[0054] Wherein, the reaction raw material that embodiment 1~embodiment 5 adopts is shown in Table 1:

[0055] The reaction raw materials that table 1 embodiment 1~embodiment 5 adopts

[0056]

[0057] The ratio between each raw material of embodiment 1~embodiment 5 is shown in Table 2:

[0058] The mass ratio between each raw material of table 2 embodiment 1~embodiment 5

[0059]

[0060] The preparation parameter of embodiment 1~embodiment 5 product is shown in Table 3:

[0061] The preparation parameter of the product that table 3 embodiment 1~embodiment 5 makes

[0062]

Embodiment 2

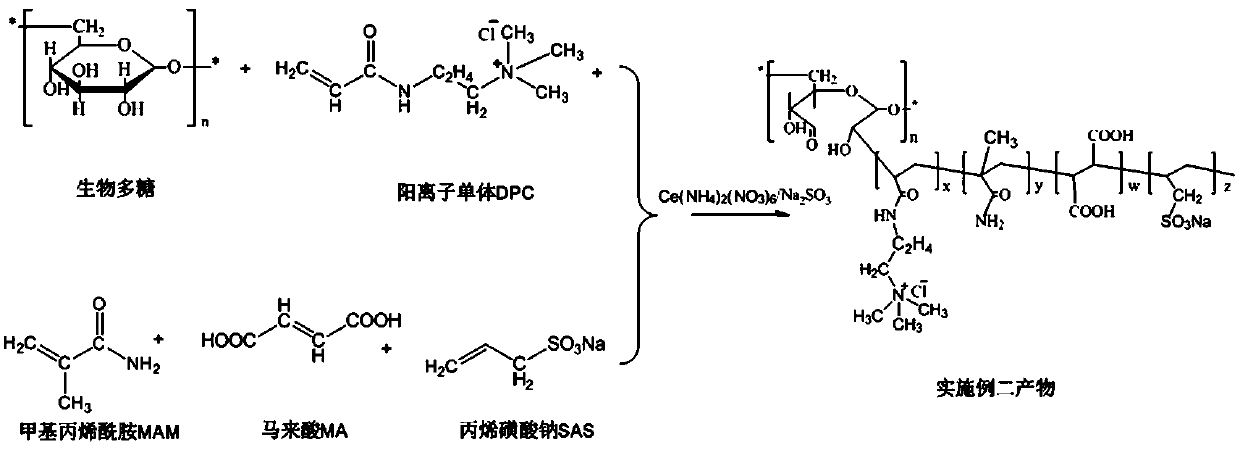

[0065] The reaction formula of embodiment 2 is as figure 2 shown;

[0066] The performance test method of paper dry strength agent is as follows:

[0067] (1) Sample preparation

[0068] 1. Experimental slurry: slurry without adding chemicals.

[0069] 2. Experimental drugs: ① dry strength agent prepared in Example 1 and Example 2, ② other products in the same industry: comparative example 1-paper dry strength agent from Arakawa, Japan, comparative example 2-paper dry strength agent from Japan Starlight, Comparative Example 3 - Zhejiang Xinyong T301.

[0070] 3. Dissolved concentration of experimental drugs: 2% and 10%.

[0071] 4. Experimental equipment: paper former, computer measurement and control paper breakage tester DCP-NPY 1200 and BTG DFR-05 dynamic water filter

[0072] (two), sample test

[0073] 1. Burst index test

[0074] Under the condition of selecting the same quantity and the same dosing amount, the burst index of the paper obtained in the experiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com