Liquid metal solidification in-situ observation device and observation method under microgravity state

A liquid metal, observation device technology, applied in the investigation phase/state change and other directions, can solve the problems of low loading accuracy and efficiency, improve accuracy and efficiency, avoid manual operation, and reduce the possibility of false touch and over-adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the embodiments and the drawings:

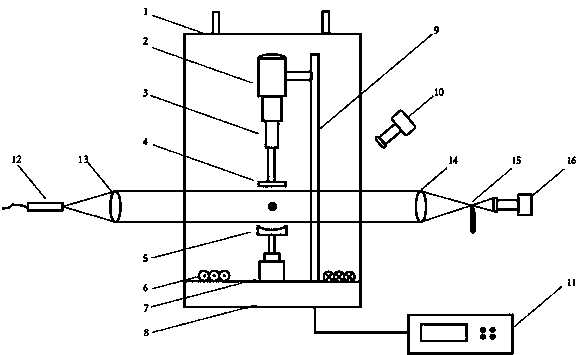

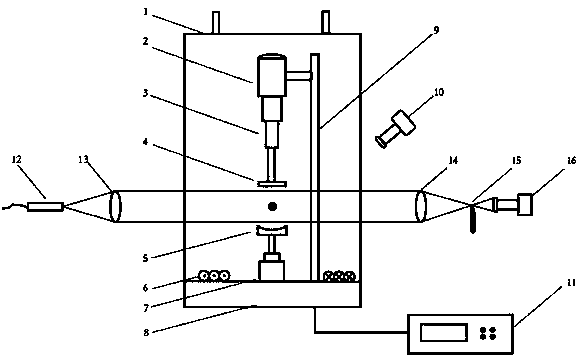

[0036] An in-situ observation device for solidification of liquid metal in a microgravity state of the present invention includes an ultrasonic levitation system and a sound field visualization system; the ultrasonic levitation system includes a transparent cover 1, an ultrasonic transducer 2, an horn 3, and an acoustic emission End 4, sound reflection end 5, cooling copper tube 6, electric adjustment support 7, support base 8, support rod 9, observation camera 10, ultrasonic generator 11; the sound field visualization system includes light source 12, front convex lens 13, rear Convex lens 14, knife edge 15, observation camera 16.

[0037] The transparent cover 1 is made of optically transparent quartz glass, and is connected to the support base 8 by a reinforced flexible gasket to form a closed cavity; in the cavity, the ultrasonic transducer 2 is fixed on the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com