Polyurethane-based spray-type photocurable hydrogel dressing precursor and preparation method

A technology of light curing and precursor liquid, applied in the field of medical materials, can solve the problems of large safety risks of organic solvents, limited use of dressings, limited clinical use, etc., to prolong the curing time, avoid potential safety hazards, and help wound healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 13.34g of isophorone diisocyanate and 24g of polytetrahydrofuran diol-2000 into a three-neck flask (100mL) equipped with a thermometer, a reflux condenser and a stirrer, add 2-3 drops of stannous octoate dropwise, Under the condition of nitrogen gas mixing and stirring for 3h. Then, the temperature was lowered to 50° C., 2.4 g of 2,2-dimethylolpropionic acid were respectively added into the above reaction system, and the temperature was kept and stirred for 2 h. Afterwards, the temperature was lowered to 57° C. and the stirring was continued for 0.5 to 1 hour to obtain a polyurethane prepolymer. Finally, 2.02 g of triethylamine was added to 97.44 g of deionized water to prepare an emulsified neutralization solution. At room temperature, slowly add the prepared polyurethane prepolymer into the neutralizing solution, and stir at a high speed for about 2 hours with a shear emulsifier to obtain an anionic polyurethane emulsion with a water content of 70 wt%. Emulsion ...

Embodiment 2

[0039] Add 13.34g of isophorone diisocyanate and 24g of polytetrahydrofuran diol-2000 into a three-neck flask (100mL) equipped with a thermometer, a reflux condenser and a stirrer, add 2-3 drops of stannous octoate dropwise, Under the condition of nitrogen gas mixing and stirring for 3h. Then, the temperature was lowered to 60° C., and a certain amount of 2.14 g of methyldiethanolamine was added to the above reaction system, and the temperature was kept and stirred for 2 hours. Afterwards, an appropriate amount of acetone (5-20 mL) was added to adjust the viscosity of the reaction system, the temperature was lowered to 57° C. and stirring was continued for 0.5-1 h to obtain a PU prepolymer. Finally, 2.3 g of acetic acid was added to 97.44 g of deionized water to prepare an emulsified neutralization solution. At room temperature, slowly add the prepared polyurethane prepolymer into the neutralizing solution, and stir at a high speed for about 2 hours with a shear emulsifier to...

Embodiment 3

[0043] Add 13.34g of isophorone diisocyanate and 24g of polytetrahydrofuran diol-2000 into a three-neck flask (100mL) equipped with a thermometer, a reflux condenser and a stirrer, add 2-3 drops of stannous octoate dropwise, Under the condition of nitrogen gas mixing and stirring for 3h. Then, the temperature was lowered to 50° C., 2.4 g of 2,2-dimethylolpropionic acid were respectively added into the above reaction system, and the temperature was kept and stirred for 2 h. Afterwards, the temperature was lowered to 57° C. and the stirring was continued for 0.5 to 1 hour to obtain a polyurethane prepolymer. Finally, 2.02 g of triethylamine was added to 97.44 g of deionized water to prepare an emulsified neutralization solution. At room temperature, slowly add the prepared polyurethane prepolymer into the neutralizing solution, and stir at a high speed for about 2 hours with a shear emulsifier to obtain an anionic polyurethane emulsion with a water content of 70 wt%.

[0044] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

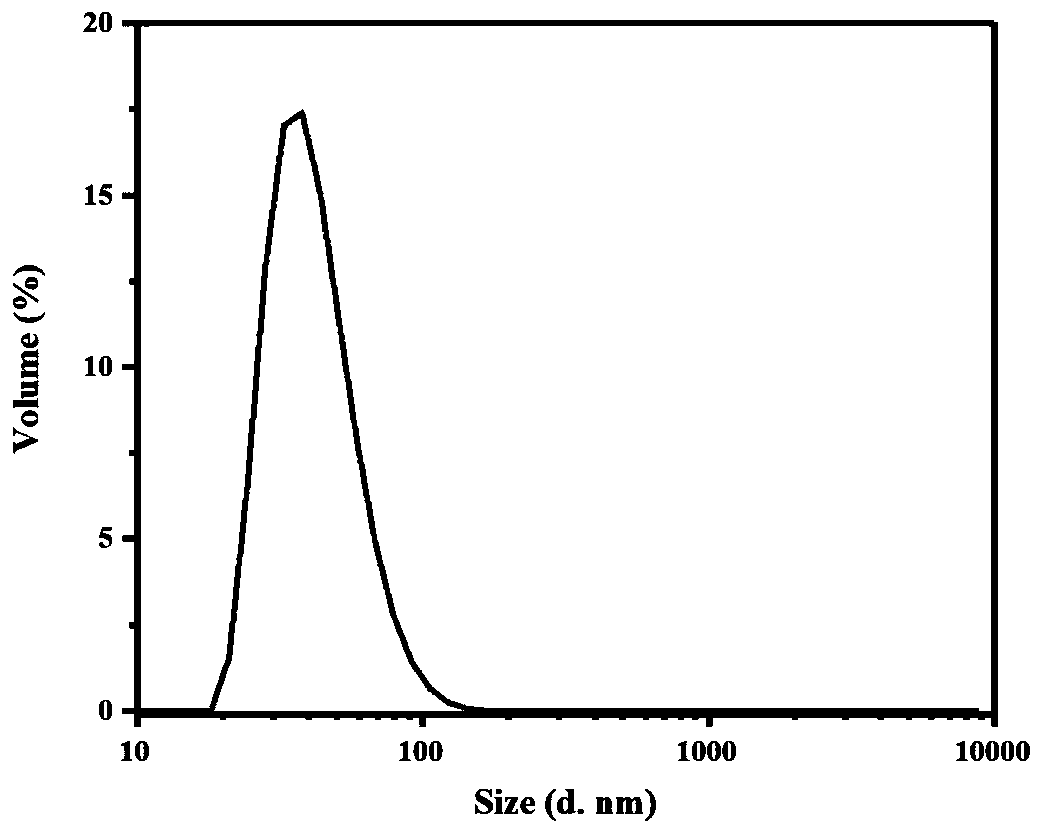

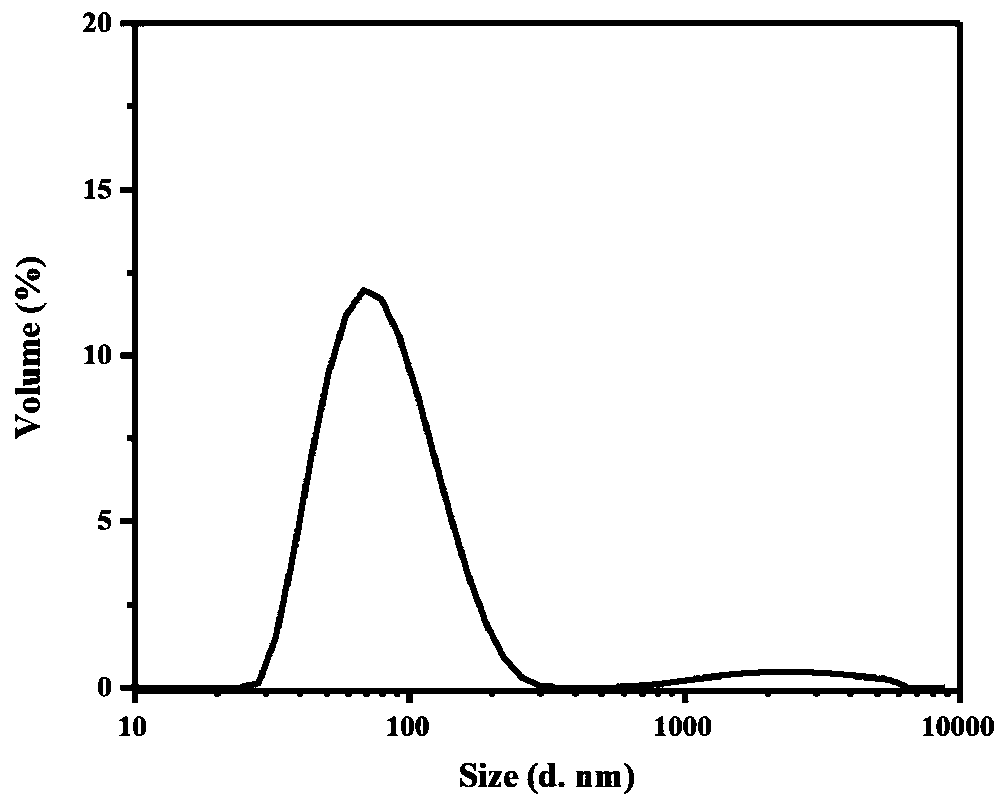

| Particle size distribution | aaaaa | aaaaa |

| Complex viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com