Special catalyst for high-concentration organic wastewater treatment and wastewater treatment method

A technology for organic wastewater treatment and wastewater treatment, which is applied in the direction of physical/chemical process catalysts, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of easy separation of photocatalysts, low utilization rate of sunlight, and increased treatment costs. The effect is stable and reliable, the investment cost is low, and the water quality of the effluent is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

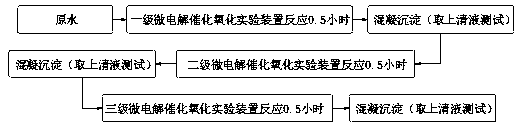

Method used

Image

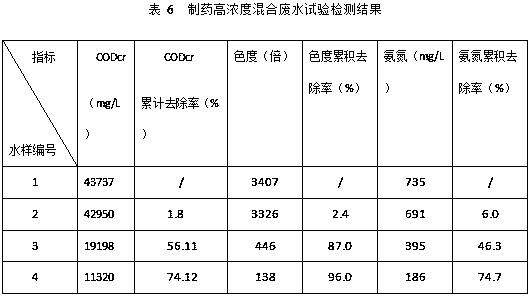

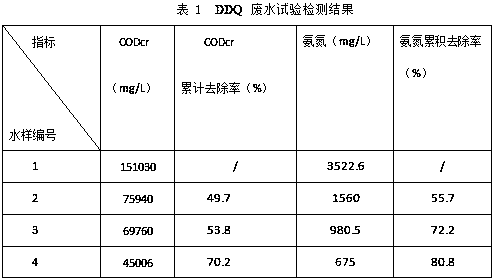

Examples

Embodiment 1

[0071] A special catalyst for high-concentration organic wastewater treatment, including the following metal elements in parts by mass: 10 parts of Ni, 10 parts of Rb, 5 parts of Mn, 5 parts of Zn, 15 parts of Ti, 15 parts of Co, 15 parts of Cu, and 15 parts of Fe , Mo 15 parts.

[0072] Based on the above raw material ratio, the catalyst uses activated carbon with high iodine value as the carrier, and the activated carbon is required to absorb iodine value not less than 1000mg / g, and Ni, Rb, Mn, Zn, Ti, Co, Cu, Fe, Mo, etc. are added Metal elements are formed by grinding, granulating, carbonizing, and activating. The specific preparation steps of the catalyst are as follows: Add Ni, Rb, Mn, Zn, Ti, Co, Cu, Fe, Mo metal elements and crush them. The grinding particle size is 200 At the same time, various metal elements are mixed and ground together, and then the binder is added. The granulator is used for granulation. The shape of the catalyst is cylindrical, the diameter of th...

Embodiment 2

[0074] A special catalyst for high-concentration organic wastewater treatment, including the following metal elements in parts by mass: 10 parts of Ni, 20 parts of Rb, 5 parts of Mn, 5 parts of Zn, 15 parts of Ti, 5 parts of Co, 15 parts of Cu, and 15 parts of Fe , Mo 15 parts.

[0075]Based on the above raw material ratio, the catalyst uses activated carbon with high iodine value as the carrier, and the activated carbon is required to absorb iodine value not less than 1000mg / g, and Ni, Rb, Mn, Zn, Ti, Co, Cu, Fe, Mo, etc. are added Metal elements are formed by grinding, granulating, carbonizing, and activating. The specific preparation steps of the catalyst are as follows: Add Ni, Rb, Mn, Zn, Ti, Co, Cu, Fe, Mo metal elements and crush them. The grinding particle size is 200 At the same time, various metal elements are mixed and ground together, and then the binder is added. The granulator is used for granulation. The shape of the catalyst is cylindrical, the diameter of the ...

Embodiment 3

[0077] A special catalyst for high-concentration organic wastewater treatment, including the following metal elements in parts by mass: 15 parts of Ni, 15 parts of Rb, 10 parts of Mn, 10 parts of Zn, 10 parts of Ti, 10 parts of Co, 10 parts of Cu, and 10 parts of Fe , Mo 10 parts.

[0078] Based on the above raw material ratio, the catalyst uses activated carbon with high iodine value as the carrier, and the activated carbon is required to absorb iodine value not less than 1000mg / g, and Ni, Rb, Mn, Zn, Ti, Co, Cu, Fe, Mo, etc. are added Metal elements are formed by grinding, granulating, carbonizing, and activating. The specific preparation steps of the catalyst are as follows: Add Ni, Rb, Mn, Zn, Ti, Co, Cu, Fe, Mo metal elements and crush them. The grinding particle size is 200 At the same time, various metal elements are mixed and ground together, and then the binder is added. The granulator is used for granulation. The shape of the catalyst is cylindrical, the diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com