Bismuth vanadate/chromium porphyrin/graphene quantum dot two-dimensional composite Z-type photocatalytic material, preparation method and application

A technology of graphene quantum dots and photocatalytic materials, applied in the directions of organic compound/hydride/coordination complex catalysts, catalyst activation/preparation, chemical instruments and methods, etc., to achieve mild preparation conditions, great application value and prospects, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

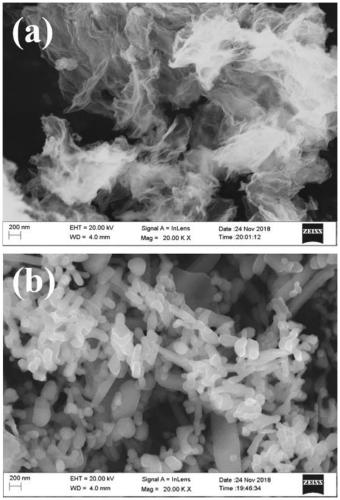

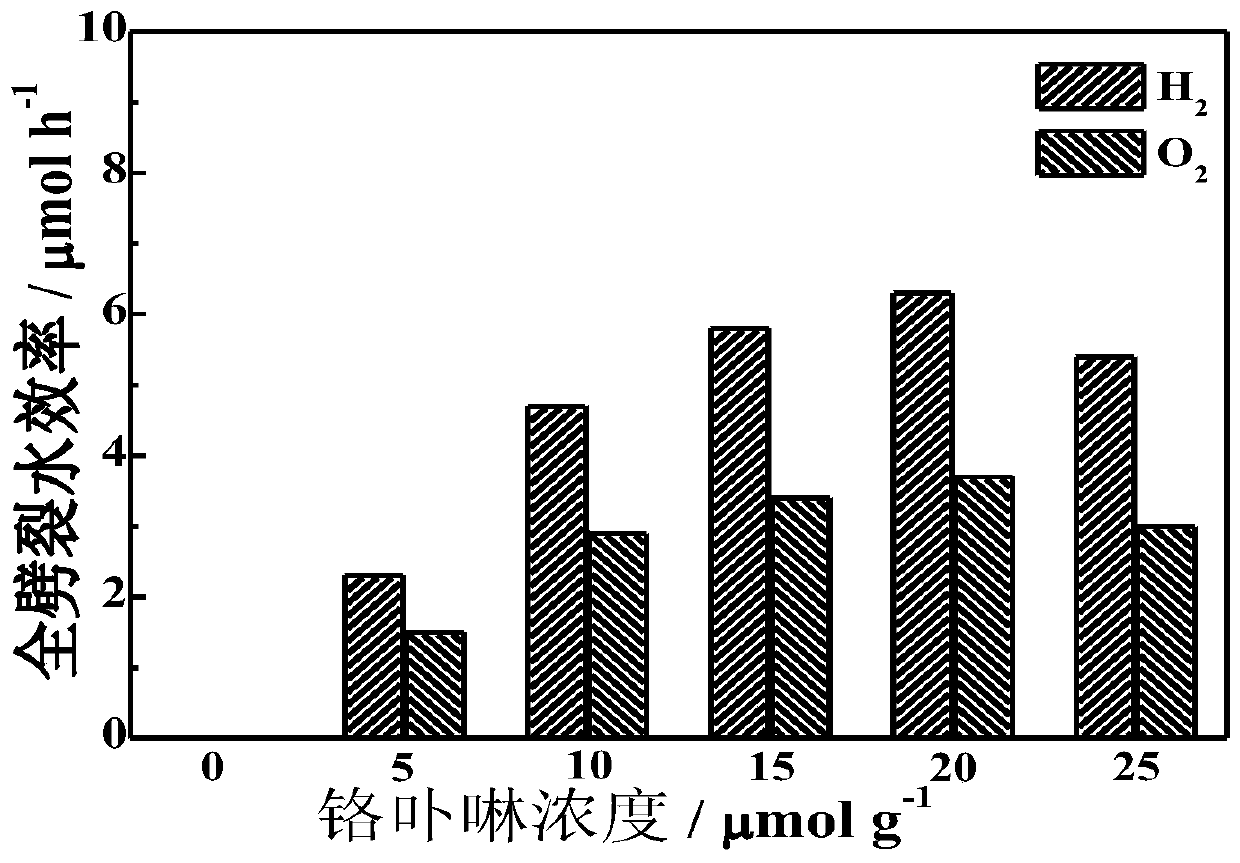

[0035] 0.5mmol Bi(NO 3 ) 3 ·5H 2 O dissolved in 35 mL HNO 3 (4M) formulated into Bi(NO 3 ) 3 solution, 0.5 mmol NH 4 VO 3 Dissolved in NaOH (2M) to make NH 4 VO 3 solution, 120mg of graphene quantum dots (GOD) was added to the above Bi(NO 3 ) 3 solution, after stirring for 30 min, add NH 4 VO 3 solution, adjust the solution to pH = 7.0, hydrothermally treat at 180°C for 3h, and wash the hydrothermal product with deionized water and ethanol to obtain BiVO 4 / GOD product. 0.1g BiVO 4 / GOD was added to 10mL (0.05mM) chromium porphyrin DMF solution, after stirring for 72h, the product was collected by rotary evaporation to obtain 5μmol g -1 Chromium porphyrin loaded BiVO4 / GOD / CrPyCl. To containing 4.0mg Pt (NH 3 ) 4 (NO 3 ) 2 0.2g BiVO4 / GOD / CrPyCl was added to the aqueous solution (40mL), stirred for 1h, the product was collected by rotary evaporation, and treated overnight at 120°C in air to obtain PtO with 1.0wt% platinum loading x -BiVO 4 / GOD / CrPyCl.

[0...

Embodiment 2

[0038] 0.5mmol Bi(NO 3 ) 3 ·5H 2 O dissolved in 35 mL HNO 3 (4M) formulated into Bi(NO 3 ) 3 solution, 0.5 mmol NH 4 VO 3 Dissolved in NaOH (2M) to make NH 4 VO 3 solution, 120mg of graphene quantum dots (GOD) was added to the above Bi(NO 3 ) 3 solution, after stirring for 30 min, add NH 4 VO 3 solution, adjust the solution to pH 7.0, hydrothermally treat at 180°C for 3h, and wash the hydrothermal product with deionized water and ethanol to obtain BiVO 4 / GOD product. 0.1g BiVO 4 / GOD was added to 10mL (0.1mM) chromium porphyrin DMF solution, stirred for 72h, and the product was collected by rotary evaporation to obtain 10μmol g -1 Chromium porphyrin loaded BiVO4 / GOD / CrPyCl. To containing 4.0mg Pt (NH 3 ) 4 (NO 3 ) 2 Add 0.2g BiVO4 / GOD / CrPyCl to an aqueous solution (40mL), stir for 1h, collect the product by rotary evaporation, and treat it overnight at 120°C in air to obtain PtO with 1.0wt% platinum loading x -BiVO4 / GOD / CrPyCl.

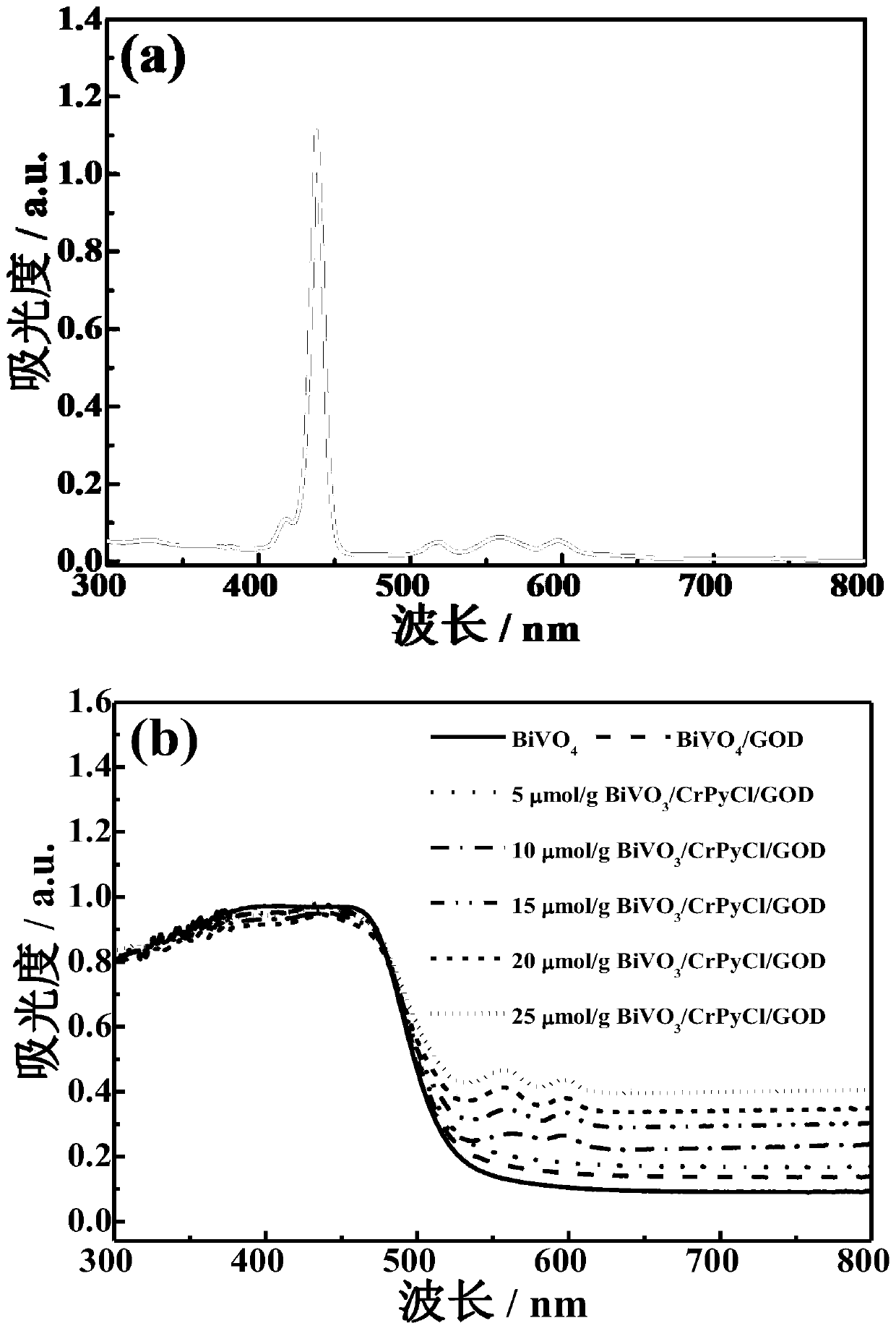

[0039] figure 2 b is Bi...

Embodiment 3

[0041] 0.5mmol Bi(NO 3 ) 3 ·5H 2 O dissolved in 35 mL HNO 3 (4M) formulated into Bi(NO 3 ) 3 solution, 0.5 mmol NH 4 VO 3 Dissolved in NaOH (2M) to make NH 4 VO 3 solution, 120mg of graphene quantum dots (GOD) was added to the above Bi(NO 3 ) 3 solution, after stirring for 30min, after adding NH 4 VO 3 solution, adjust the solution to pH 7.0, hydrothermally treat at 180°C for 3h, and wash the hydrothermal product with deionized water and ethanol to obtain BiVO 4 / GOD product. 0.1g BiVO 4 / GOD was added to 10mL (0.15mM) chromium porphyrin DMF solution, after stirring for 72h, the product was collected by rotary evaporation to obtain 15μmol g -1 Chromium porphyrin loaded BiVO4 / GOD / CrPyCl. To containing 4.0mg Pt (NH 3 ) 4 (NO 3 ) 2 0.2g BiVO4 / GOD / CrPyCl was added to the aqueous solution (40mL), stirred for 1h, the product was collected by rotary evaporation, and treated overnight at 120°C in air to obtain PtO with 1.0wt% platinum loading x - BiVO4 / GOD / CrPyCl p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com