Method for preparing nano-spherical barium titanate through micro-channel continuous process

A continuous method, nano-scale technology, applied in the direction of titanate, nanotechnology, alkaline earth metal titanate, etc., can solve the problems of long reaction cycle, cumbersome feeding operation, etc., and achieve the effect of accelerating reaction efficiency and shortening reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

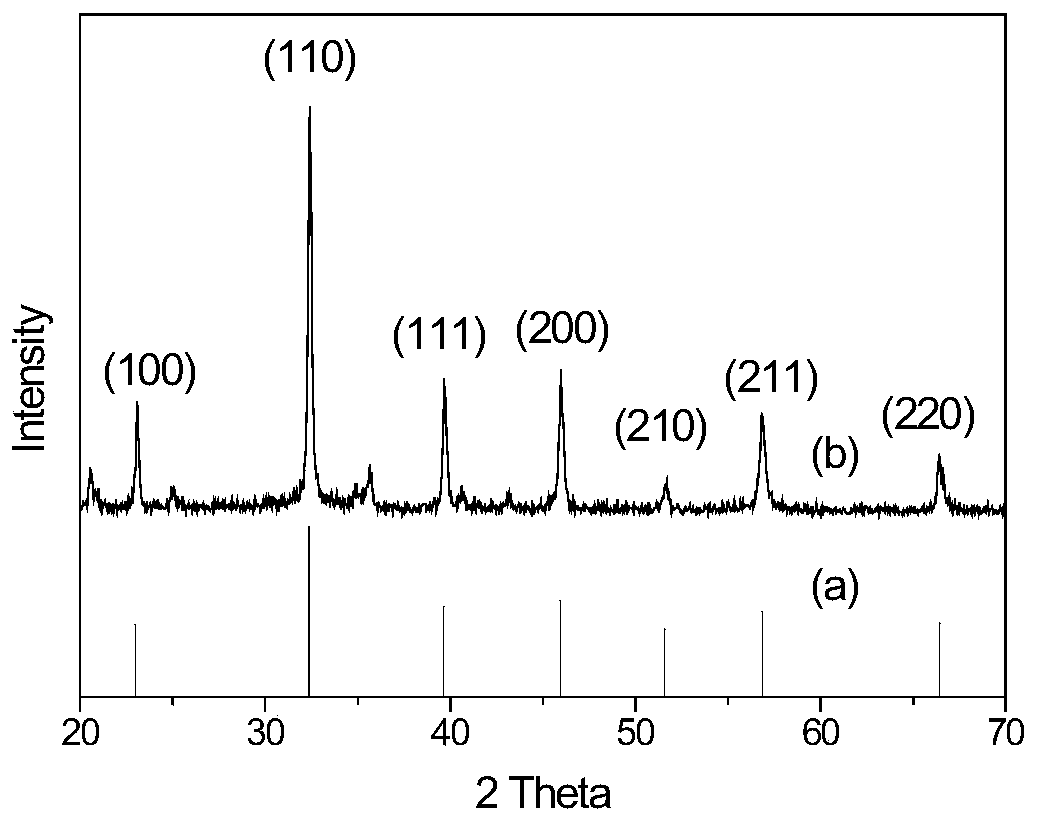

[0036] The experiment uses cheap soluble barium salt as BaCl 2 2H 2 O, analytically pure; soluble titanium salt is TiCl 4 , analytically pure; the precipitating agent used was NaOH, analytically pure; the constant temperature water bath was set to 90°C before the experiment.

example 1

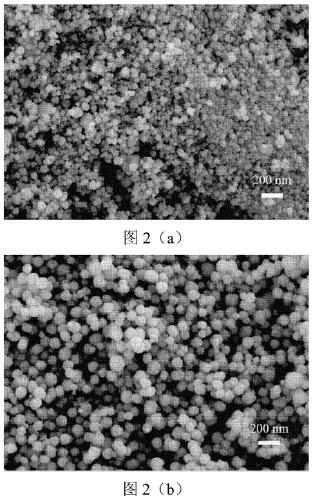

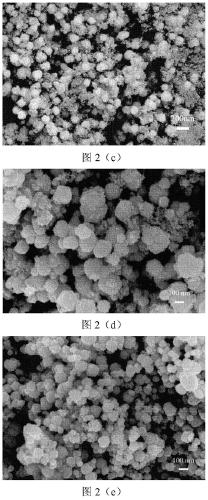

[0038] Stir the 3mol / L NaOH solution evenly and cool it down to room temperature as liquid A. At the same time, prepare 0.15mol / L BaCl 2 solution; according to the Ba / Ti molar ratio of 1.10, the TiCl 4 Add it dropwise into deionized water to obtain the same amount of Ti liquid, and then mix the two evenly to obtain B liquid. Put liquid A and liquid B at a flow rate of 1mL / min into the T-type mixer through a convection pump, flow through a microchannel pipeline with a length of 5m and an inner diameter of 1mm, centrifuge the white precipitate obtained at the outlet of the pipeline, and wash it several times After drying in an oven at 80°C for 12 hours, spherical BaTiO with an average particle size of 40 nm was obtained. 3 Powder.

example 2

[0040] Stir the 3mol / L NaOH solution evenly and cool it down to room temperature as liquid A. At the same time, prepare 0.15mol / L BaCl 2 solution; according to the Ba / Ti molar ratio of 1.0, the TiCl 4 Add it dropwise into deionized water to obtain the same amount of Ti liquid, and then mix the two evenly to obtain B liquid. Pour liquid A and liquid B into the T-type mixer through a convection pump at a flow rate of 2 mL / min, flow through a microchannel pipeline with a length of 5 m and an inner diameter of 0.5 mm, and centrifuge the white precipitate obtained at the outlet of the pipeline for several times. After washing, dry in an oven at 80°C for 12 hours to obtain spherical BaTiO with an average particle size of 100 nm 3 Powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com