Preparation method of polyaniline coated silver-loaded nano microcrystalline cellulose-based conductive ink

A nano-microcrystalline, cellulose-based technology, applied in ink, household utensils, applications, etc., can solve the problems of easy cracking of nano-silver, achieve the effect of improving process and formula, improving adhesion, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

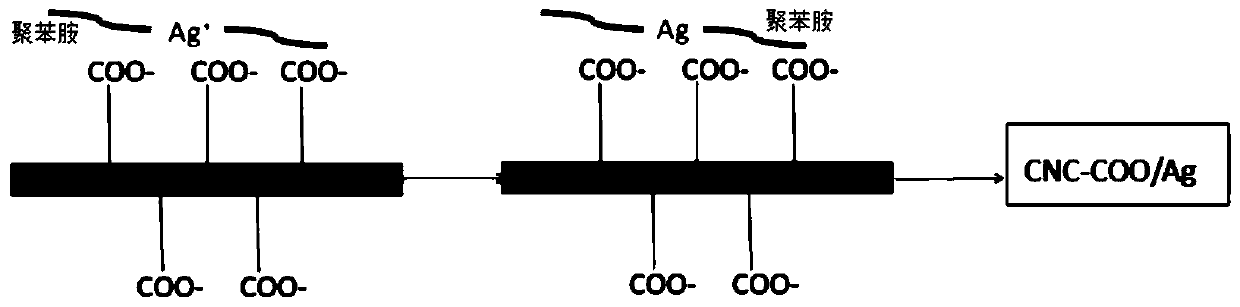

[0047] Example 1: A method for preparing polyaniline-coated silver-loaded nano-microcrystalline cellulose-based conductive ink, the principle of the method is as follows figure 1 shown, and follow the steps below:

[0048] a. Ultrasonic vibration of 48 mL of 0.3% nanocrystalline cellulose solution for 11 minutes to obtain a nanocrystalline cellulose suspension solution; then add 28 mL of a 0.1% silver nitrate solution to the nanocrystalline cellulose suspension solution, and ultrasonically disperse Stir for 5 minutes to make it evenly mixed;

[0049] b. Slowly add 25 mL of sodium borohydride solution with a concentration of 0.1% to the above mixed solution, stir for 5 minutes, and use an electric stirrer to mix it evenly to obtain a silver-loaded nano-microcrystalline cellulose mixed solution; Centrifuge for 10 min, add the obtained precipitate into deionized water and wash with ultrasonic vibration for 30 min, repeat the above process several times until the supernatant is ...

Embodiment 2

[0053] Embodiment 2: a kind of preparation method of polyaniline wrapping silver-loaded nano-microcrystalline cellulose base conductive ink, and carry out according to the following steps:

[0054] a. Ultrasonic vibration of 58 mL of 0.5% nanocrystalline cellulose solution for 18 minutes to obtain nanocrystalline cellulose suspension solution; then add 24 mL of 0.1% silver nitrate solution to the nanocrystalline cellulose suspension solution, and ultrasonically disperse Stir for 5 minutes to make it evenly mixed;

[0055] b. Slowly add 25mL of 0.1% sodium borohydride solution to the above mixed solution, stir for 5 minutes, and use an electric stirrer to mix it evenly to obtain the silver-loaded nano-microcrystalline cellulose mixed solution; Centrifuge for 10 minutes, add the obtained precipitate into deionized water and wash it with ultrasonic vibration for 30 minutes, repeat the above process several times until the supernatant is white, and then take the washed precipitate...

Embodiment 3

[0059] Embodiment 3: a kind of preparation method of polyaniline wrapping silver-loaded nano-microcrystalline cellulose-based conductive ink, and carry out according to the following steps:

[0060] a. 50mL concentration of 0.4% nanocrystalline cellulose solution was ultrasonically oscillated for 15min to obtain nanocrystalline cellulose suspension solution; then 25mL concentration of 0.15% silver nitrate solution was added to the nanocrystalline cellulose suspension solution, ultrasonically dispersed Stir for 5 minutes to make it evenly mixed;

[0061] b. Slowly add 25 mL of sodium borohydride solution with a concentration of 0.08% to the above mixed solution, stir for 5 minutes, and use an electric stirrer to mix it evenly to obtain a silver-loaded nano-microcrystalline cellulose mixed solution; Centrifuge for 10 minutes, add the obtained precipitate into deionized water and wash it with ultrasonic vibration for 30 minutes, repeat the above process several times until the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com