Cigarette cracking device and cigarette thermal cracking analysis method using same

A technology of cracking device and analysis method, applied in the field of cigarette testing equipment, can solve the problems of complex and small continuous adjustment of Curie point cracker temperature, generally tens of micrograms to several milligrams, and inability to thermally crack large samples, etc. The effect of avoiding the occurrence of temperature gradients inside the sample, fast heating, easy control and measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

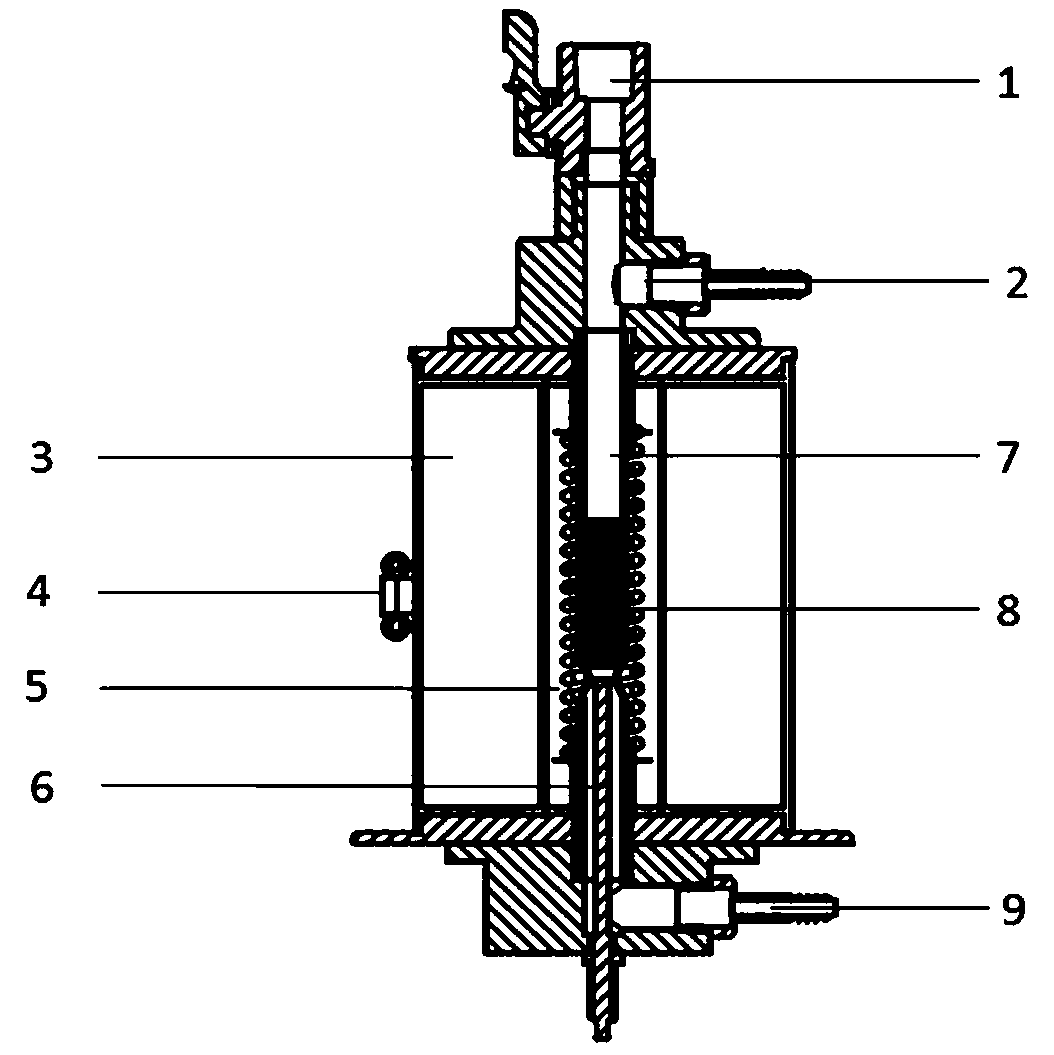

[0039] Such as Figure 1~Figure 3 As shown, the cigarette cracking device provided by the present application includes two parts, a furnace body and a control system;

[0040] Described body of furnace adopts vertical structure, comprises a cracking chamber 7 that is used to hold sample, and the outside of cracking chamber 7 is provided with electric furnace heating wire 5, and the upper end of cracking chamber 7 is connected with carrier gas inlet 2 simultaneously, and the end of cracking chamber is connected with There is a carrier gas outlet 9;

[0041] The heating wire 5 of the electric furnace is connected with a thermocouple 6, and the thermocouple 6 controls parameters such as heating time and heating temperature by a control system.

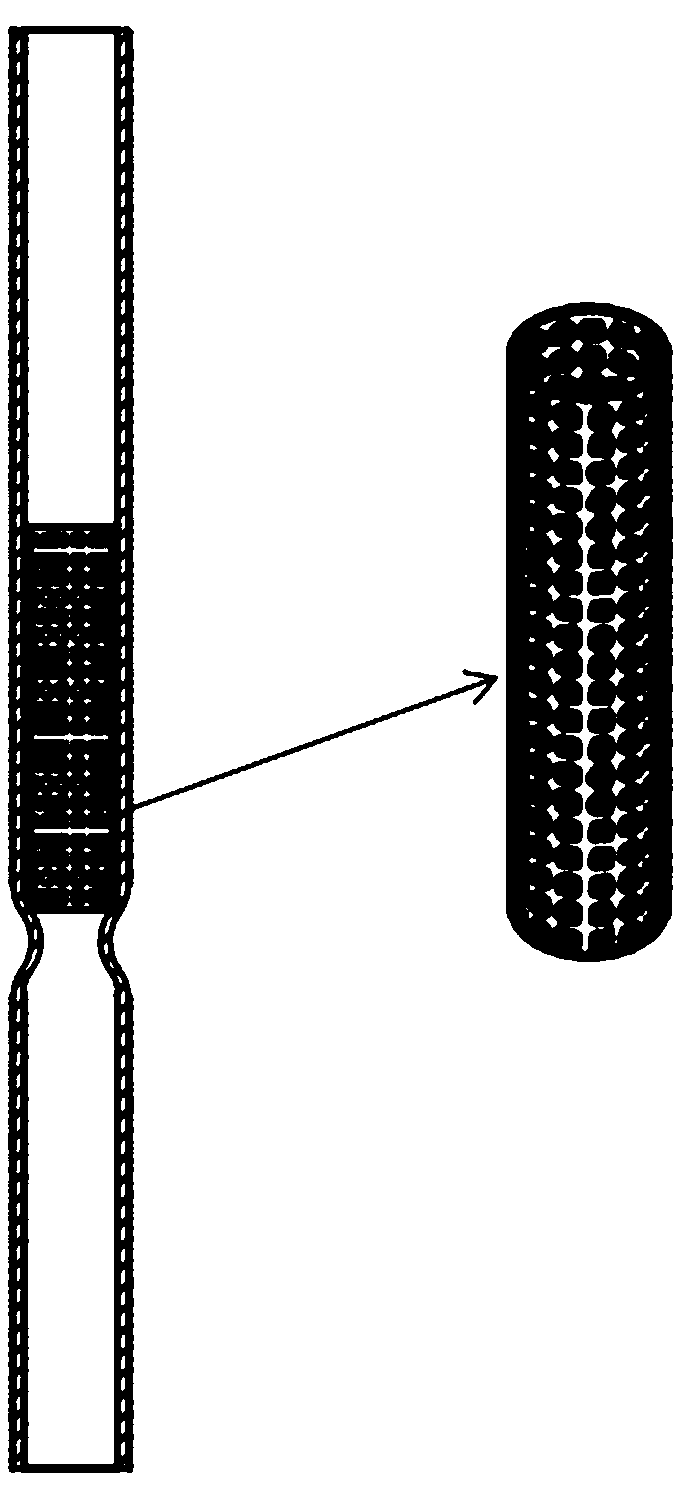

[0042] The cracking chamber 7 is used to hold the sample to be heated and cracked, and is specifically a quartz tube; the diameter of the quartz tube is matched with a sample holding cage 8, so that the sample to be heated and cracked ca...

Embodiment 2

[0055] With similar parameters of the three auxiliary materials, one cigarette sample of China Tobacco Henan Co., Ltd. with different specifications of high, medium and low tar (cigarette sample brands are: high tar soft big golden round, medium tar century-old Luzhou, low tar golden leaf Xuanshang , and numbered 1, 2, 3 respectively). According to the smoking parameters, draw out the burnt tobacco part, and then select 2 / 5 of the total burnt tobacco for pyrolysis analysis according to the distribution of mainstream smoke and sidestream smoke.

[0056] During pyrolysis analysis, the shredded tobacco sample is placed in a stainless steel mesh cage, the filter is placed in the holder, and connected to the gas outlet of the instrument.

[0057] Turn on the power of the instrument and set the cracking parameters:

[0058] The cracking gas compressed air flow rate is 20mL / min, the cracking gas flow rate is 46mL, the cracking temperature is 900°C, the heating rate is 100°C / ms, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com